System and method for controlling temperature of hydraulic oil

A hydraulic system and hydraulic oil technology, which is applied in the field of hydraulic oil temperature control system, can solve the problem of single control mode, achieve good cooling effect and improve precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

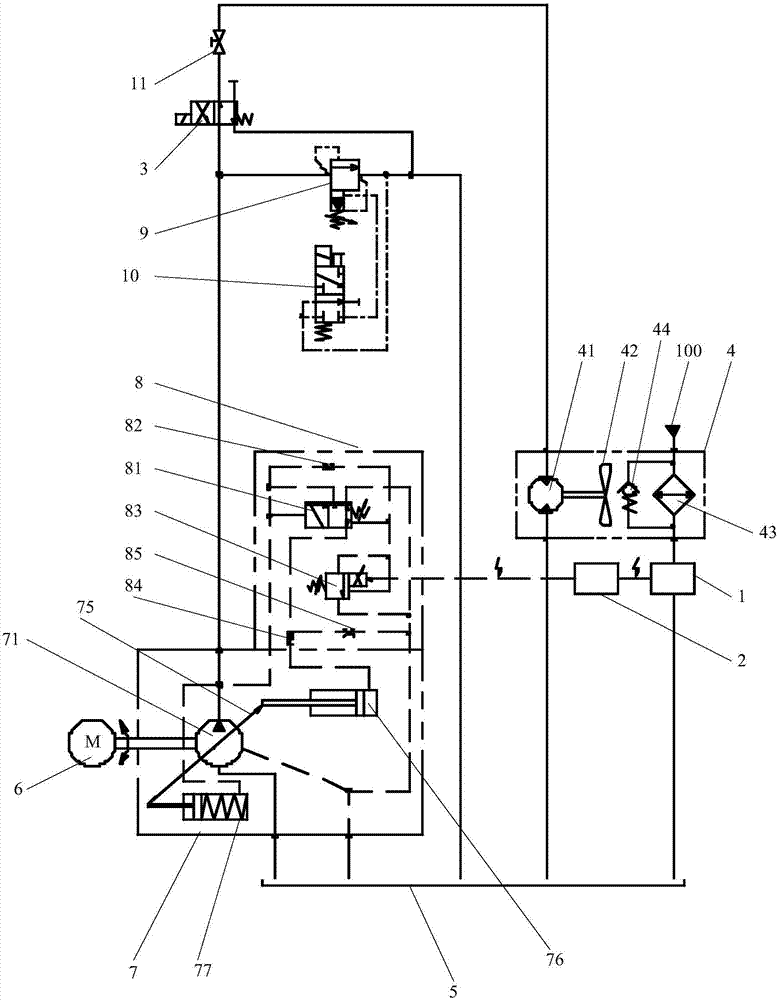

[0034] The embodiment of the present invention provides a system for controlling the temperature of hydraulic oil, see figure 1 , the system includes a temperature sensor 1, a controller 2, a first electromagnetic reversing valve 3, an air cooler 4 and an oil tank 5, the oil tank 5 is used to provide hydraulic oil for the hydraulic system, and the temperature sensor 1 is arranged at the oil outlet of the hydraulic system On the oil path between 100 and the fuel tank 5, the controller 2 is electrically connected to the temperature sensor 1.

[0035] It is easy to know that the hydraulic oil flows in the oil circuit when the oil circuit is turned on, and is stored in the oil circuit when the oil circuit is closed, so there is always hydraulic oil in the oil circuit, and the temperature sensor can detect the temperature of the hydraulic oil at any time .

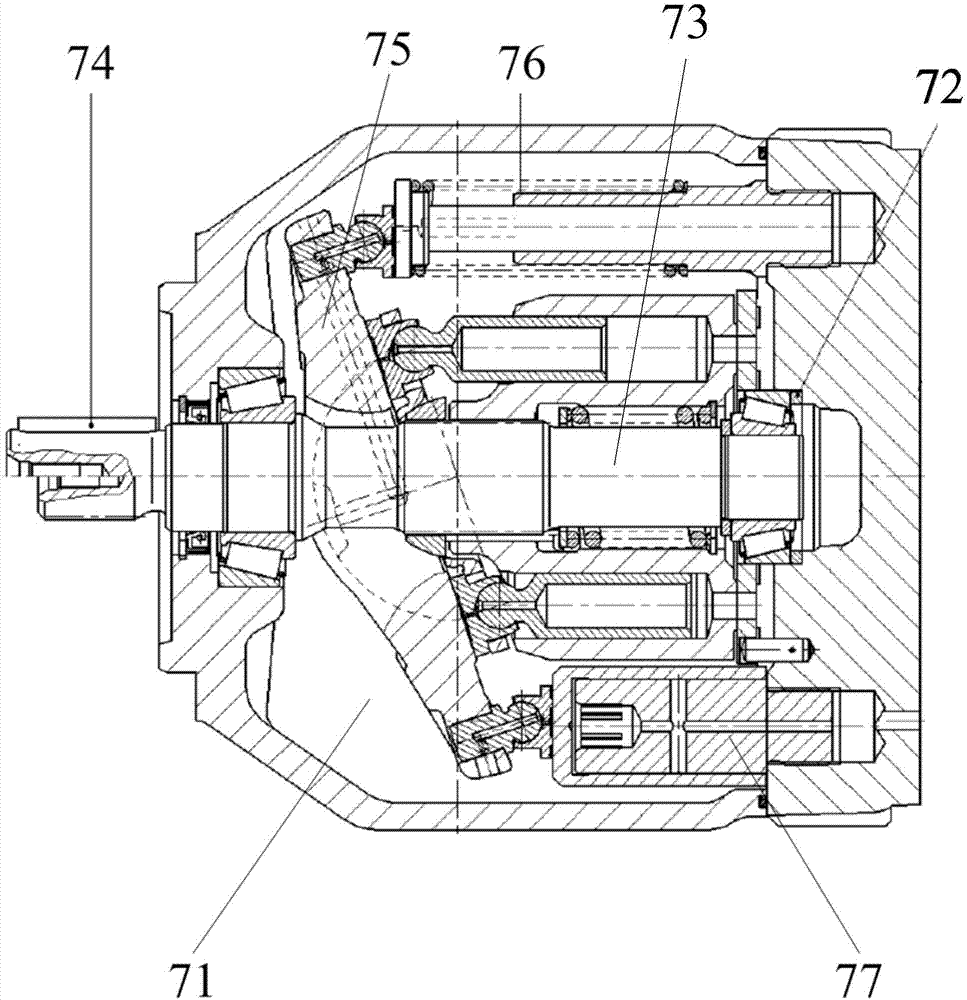

[0036] In this embodiment, the system also includes a motor 6, a variable plunger pump 7, a control valve group 8, and a pil...

Embodiment 2

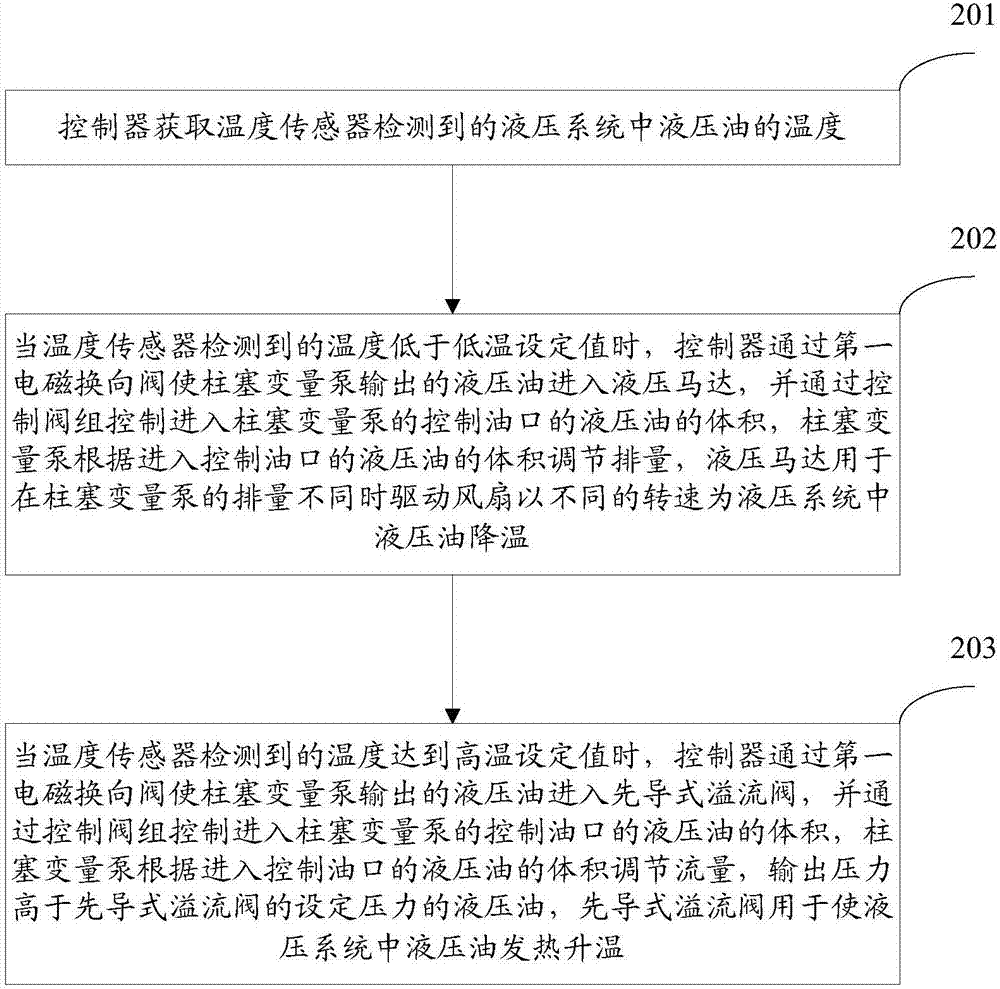

[0070] The embodiment of the present invention provides a method for controlling the temperature of hydraulic oil implemented by the system provided in Embodiment 1, see image 3 , the method includes:

[0071] Step 201: The controller acquires the temperature of the hydraulic oil in the hydraulic system detected by the temperature sensor.

[0072] Step 202: When the temperature detected by the temperature sensor reaches the high temperature setting value, the controller makes the hydraulic oil output by the plunger variable pump enter the hydraulic motor through the first electromagnetic reversing valve, and enters into the plunger variable pump through the control valve group The volume of hydraulic oil in the control oil port, the plunger variable pump adjusts the displacement according to the volume of hydraulic oil entering the control oil port, and the hydraulic motor is used to drive the fan at different speeds for hydraulic pressure when the displacement of the plunger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com