Quality-divided and graded utilization method and system of coal-burning supercritical carbon dioxide power generation flue gas energy and working medium energy

A carbon dioxide and supercritical technology, applied in indirect carbon dioxide emission reduction, combustion methods, machines/engines, etc., can solve the problems of low boiler thermal efficiency, affecting the power generation efficiency of the unit, and unavailability of flue gas waste heat, so as to improve the cycle efficiency, high Cyclic power generation efficiency and the effect of increasing the average endothermic temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

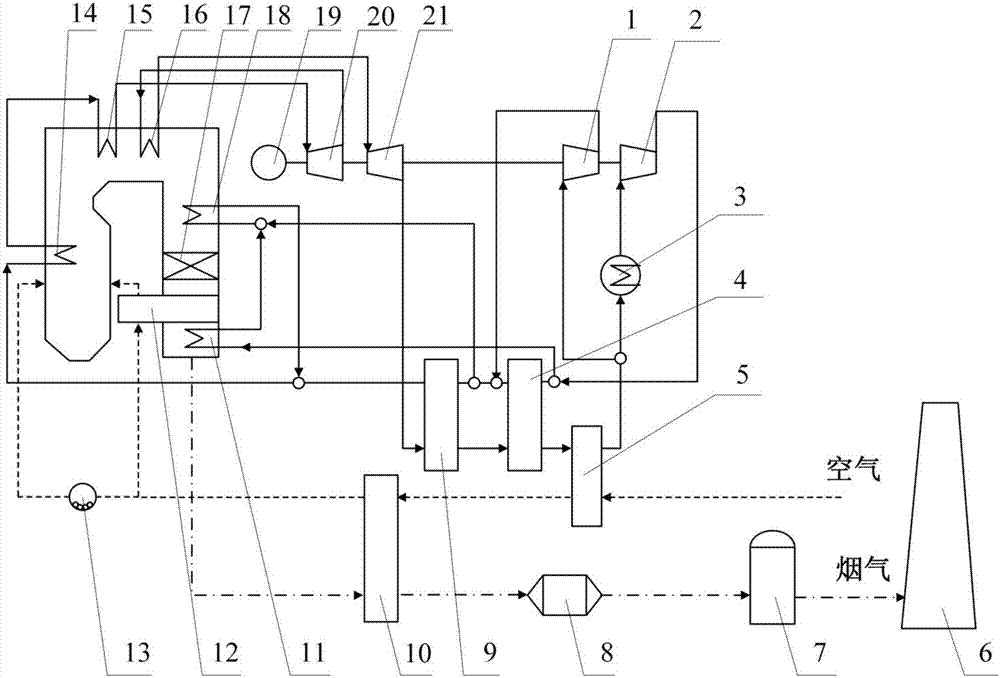

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] see figure 1 , the present invention includes a low-grade flue gas energy and working fluid energy graded heating cold air and fuel system, a medium-grade flue gas energy and working fluid energy coupling graded split flow reheating system, and a high-grade flue gas energy and working fluid energy multi-stage reheat expansion Power system;

[0023] The low-grade flue gas energy and working fluid energy can be graded to heat the cold air and the fuel system includes a primary working fluid air preheater 5 and a secondary flue gas air preheater 10 connected in sequence, and the primary working fluid The inlet of the air preheater 5 is connected to the air side, and the outlet of the secondary flue gas air preheater 10 is respectively connected to the third stage air preheater 12 installed in the flue gas channel of the boiler and the coal mill 13, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com