Low-carbon-emission composite cycle power generation system and operation method thereof

A technology of compound cycle power generation and operation method, which is applied in the directions of machines/engines, steam engine devices, gas turbine devices, etc., to achieve the effects of high thermal efficiency, solving carbon emission reduction problems, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

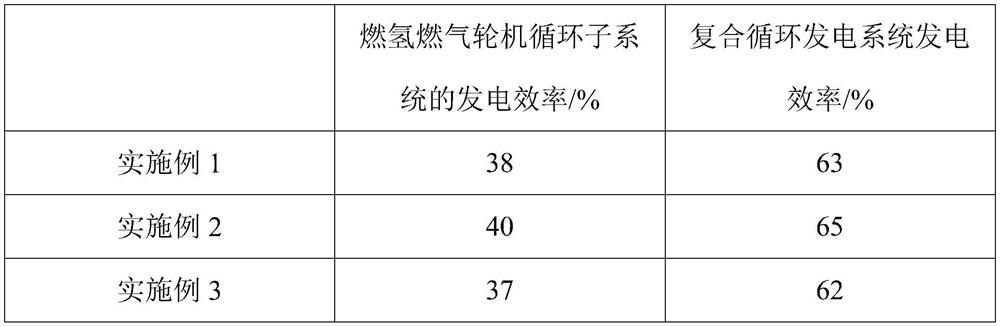

Embodiment 1

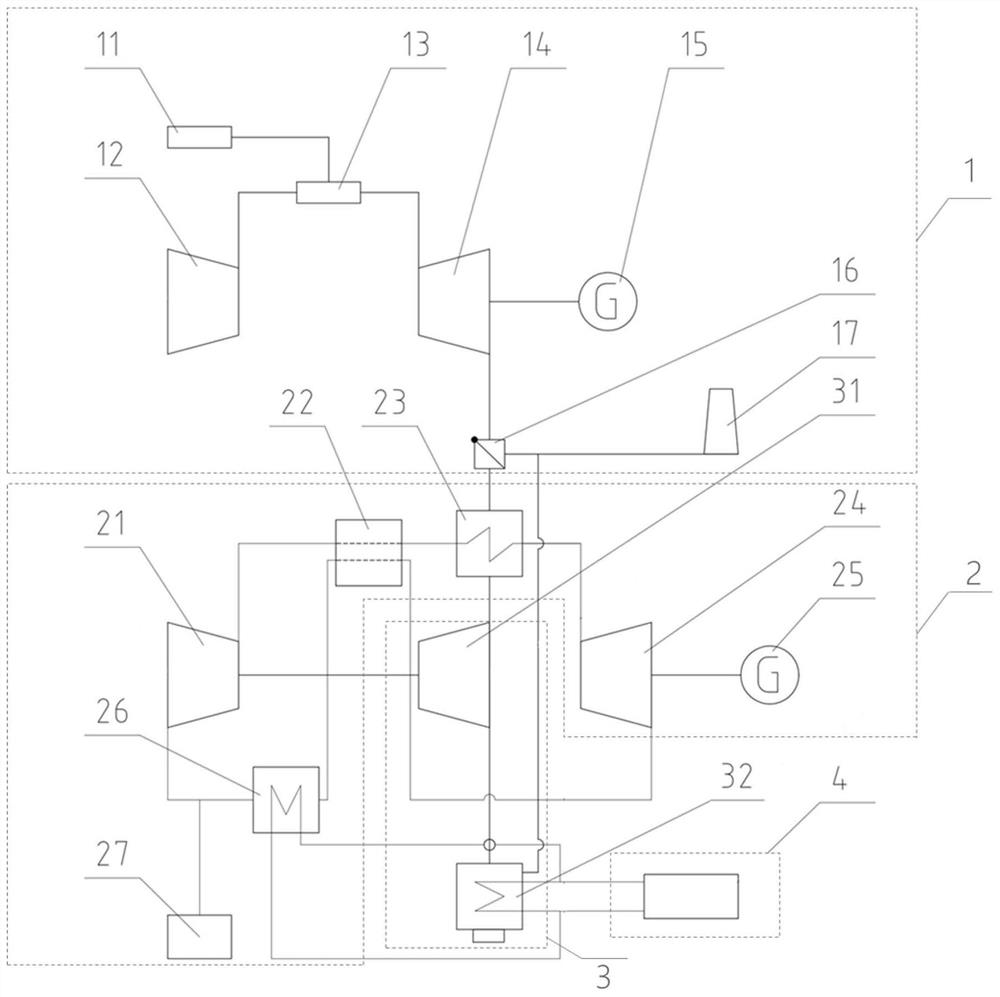

[0069] This embodiment provides a low-carbon emission compound cycle power generation system and its operation method. The flow chart of the compound cycle power generation system is as follows figure 1 shown.

[0070] The combined cycle power generation system includes a hydrogen-fired gas turbine cycle subsystem 1, a supercritical carbon dioxide cycle subsystem 2, a waste heat recovery subsystem 3, and a circulating cooling water subsystem 4 connected in sequence;

[0071] The hydrogen gas turbine cycle subsystem 1 is an open cycle; the supercritical carbon dioxide cycle subsystem 2 is a closed cycle.

[0072] The hydrogen-burning gas turbine cycle subsystem 1 includes a hydrogen fuel supply unit 11, a hydrogen-burning combustion chamber 13, a gas turbine 14, an exhaust flap door 16, and an exhaust gas discharge device 17 connected in sequence; the hydrogen-burning gas turbine cycle subsystem 1 also includes an air compressor 12 connected to the hydrogen combustion chamber ...

Embodiment 2

[0085] This embodiment provides a low-carbon emission compound cycle power generation system and its operation method, and the compound cycle power generation system is the same as the compound cycle power generation system in Embodiment 1.

[0086] The operation method comprises the following steps:

[0087] (1) After the hydrogen fuel is processed by the hydrogen fuel supply unit 11, it is supplied to the hydrogen combustion chamber 13, where it reacts with the compressed air (compression ratio 20) provided by the air compressor 12 to generate high-temperature gas at 1450°C. Expansion work in the turbine 14 drives the gas generator 15 to generate electric energy; the relative internal efficiency of the gas turbine 14 reaches 92%;

[0088] (2) In step (1), the gas exhaust after expanding and doing work enters the carbon dioxide heater 23, heats the carbon dioxide working medium from the carbon dioxide regenerator 22, and makes it reach 550 ° C, and the heated carbon dioxide wor...

Embodiment 3

[0093] This embodiment provides a low-carbon emission compound cycle power generation system and its operation method, and the compound cycle power generation system is the same as the compound cycle power generation system in Embodiment 1.

[0094] The operation method comprises the following steps:

[0095] (1) The hydrogen fuel is supplied to the hydrogen combustion chamber 13 after being processed by the hydrogen fuel supply unit 11, and undergoes a combustion reaction with the compressed air (compression ratio 17) provided by the air compressor 12 to generate high-temperature gas at 1350°C. Expansion work in the turbine 14 drives the gas generator 15 to generate electric energy; the relative internal efficiency of the gas turbine 14 reaches 89%;

[0096] (2) In step (1), the gas exhaust after expanding and doing work enters the carbon dioxide heater 23, heats the carbon dioxide working medium from the carbon dioxide regenerator 22, and makes it reach 510 ° C, and the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com