Rolling bearing fault diagnosis method based on convolutional neural network

A convolutional neural network and rolling bearing technology, which is applied in the field of mechanical equipment fault diagnosis, can solve the problems of easy submersion and difficulty in extracting feature components, and achieve the effect of preventing network overfitting, large sample size, and guaranteed sample diversity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

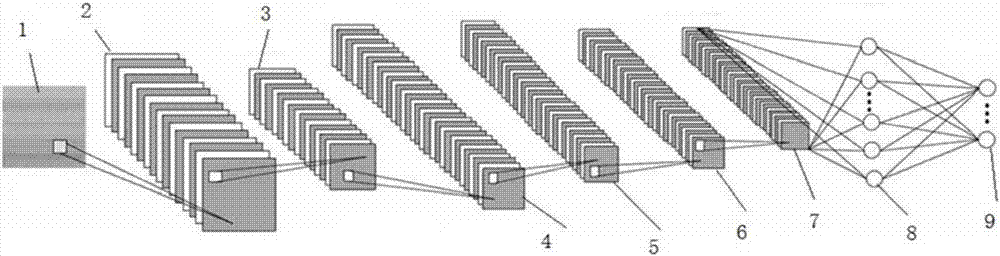

Method used

Image

Examples

Embodiment Construction

[0030] The application of the present invention in actual rolling bearing fault diagnosis will be further described in detail below in conjunction with the accompanying drawings.

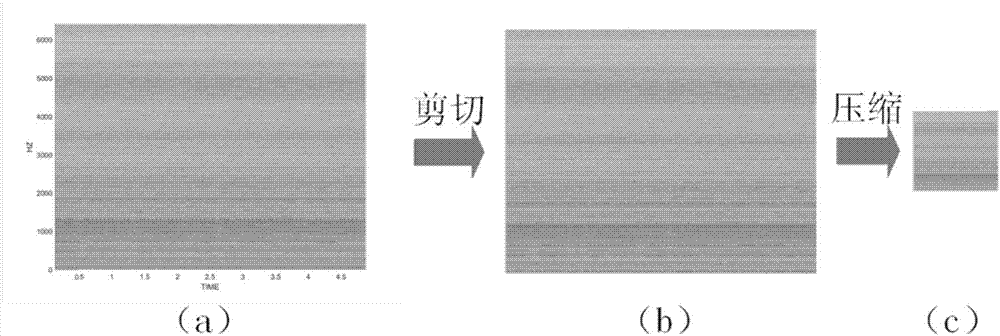

[0031] (1) Data collection and preprocessing

[0032] The power transmission system test bench used in the diagnostic method of the present invention is composed of a motor, a two-stage planetary gearbox, a fixed-axis gearbox and a magnetic powder brake. The sensor is installed on the right end cover of the fixed-axis gearbox. Different fault types, the specific fault types are shown in Table 1, where 5000 sets of time-domain signals were collected for each type of fault under the same working conditions, the sampling frequency was 5.12kHz, and the duration of each set of signals was 5s.

[0033] Table 1 Five types of failure types of bearings

[0034]

[0035] In order to improve the diversity of samples, the load size is adjusted during data collection, so that the data samples of the same fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com