Method for preparing regenerated sintered NdFeB magnet by double-sided grinding of NdFeB sludge waste

A technology of neodymium iron boron and oil sludge, which is applied in the fields of magnetic objects, solid waste removal, inductance/transformer/magnet manufacturing, etc., can solve the problems of long production cycle, high cost, serious environmental pollution, etc. Short, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

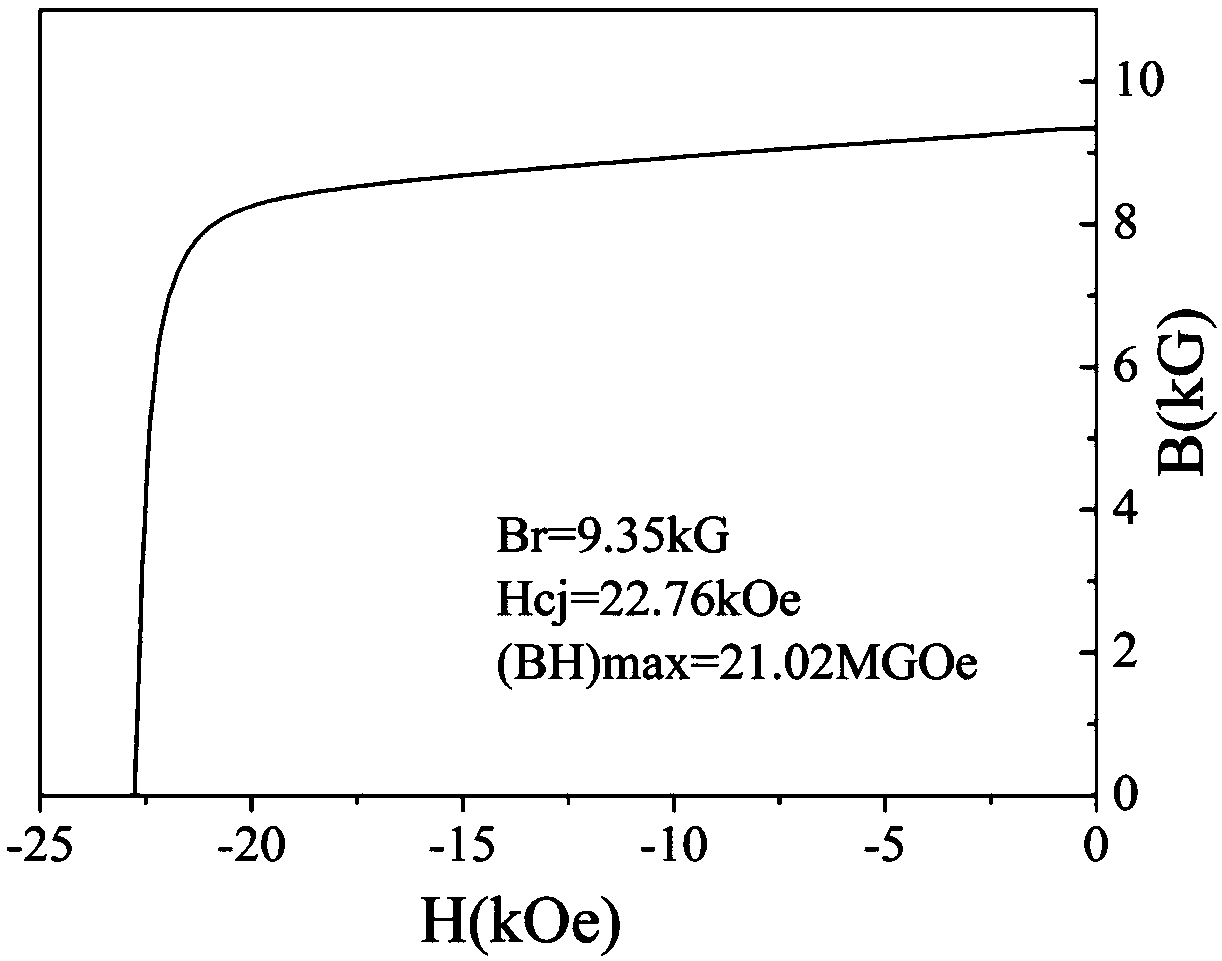

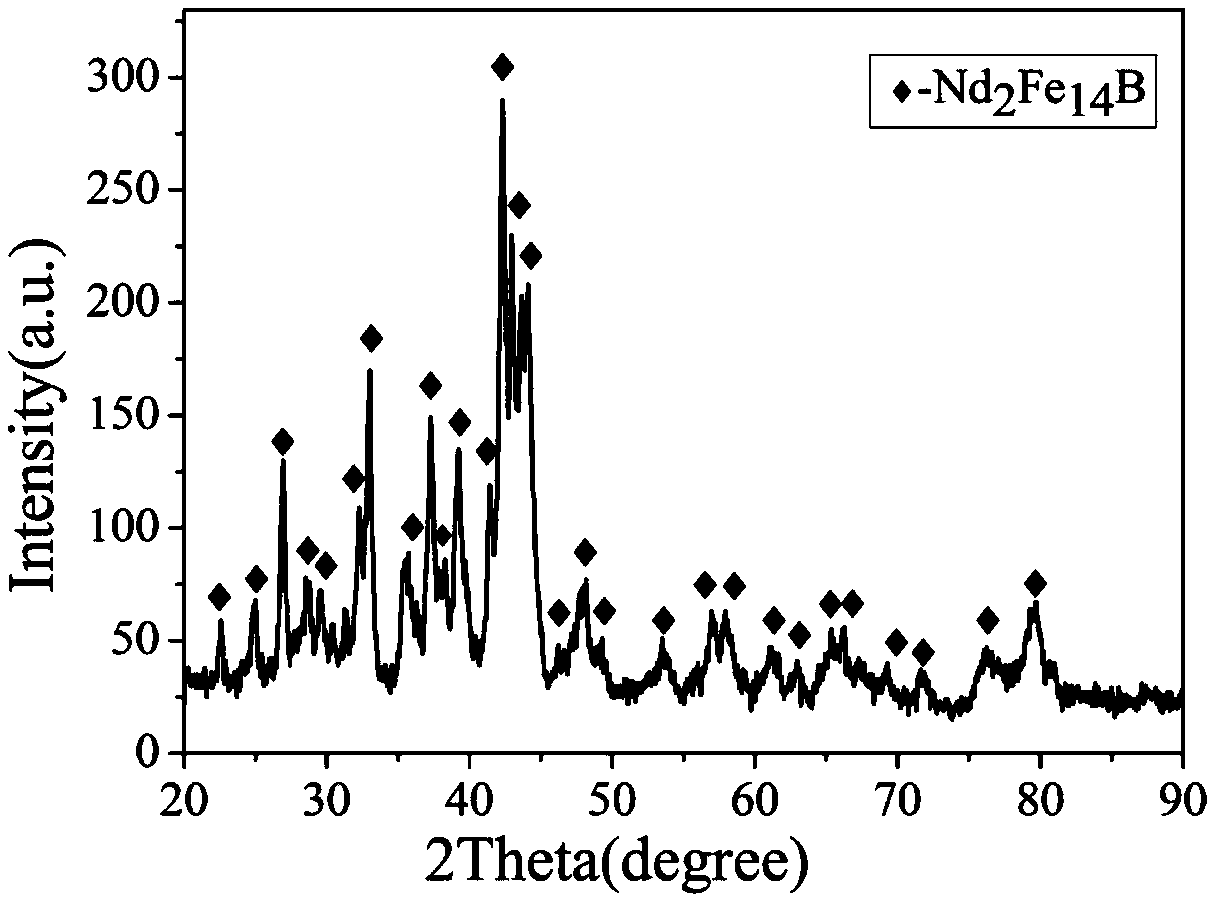

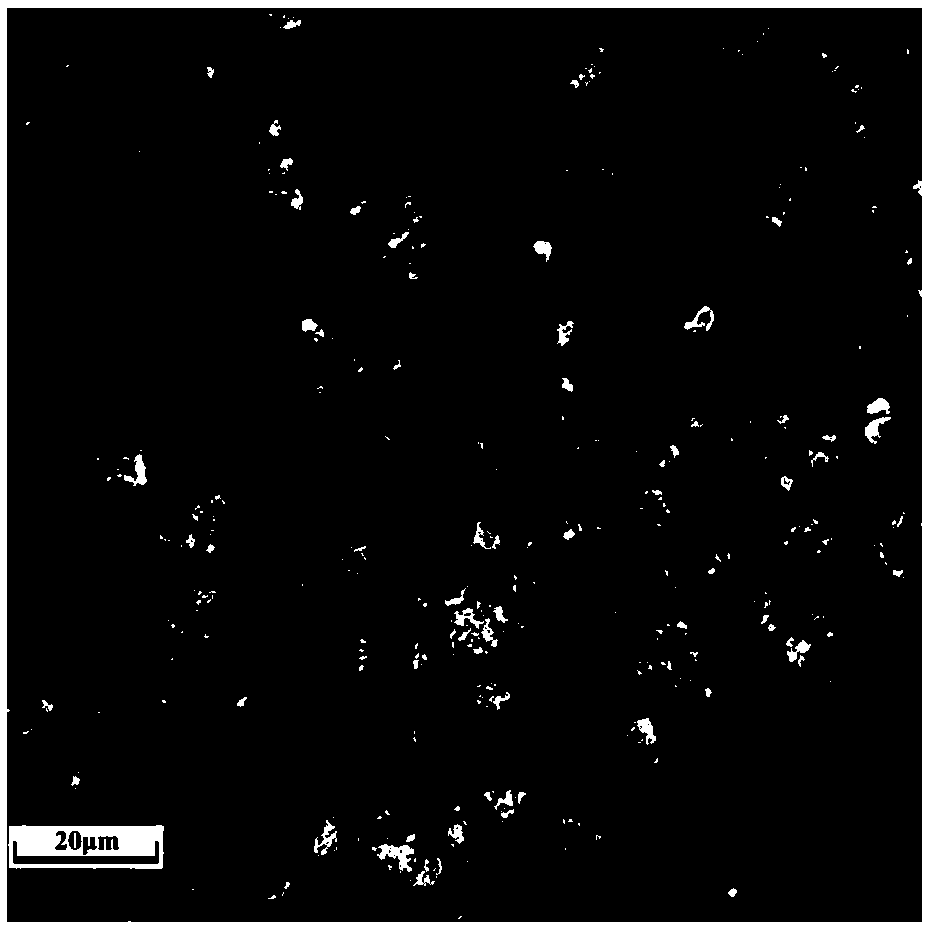

[0024] Nd in the sintered NdFeB sludge waste from double-sided grinding ① No. 2 Fe 14 Phase B and Nd 2 o 3 Phase, the rare earth content is 31.72%, the carbon content is 0.55%, the oxygen content is 8.73%, the saturation magnetization is 96.76emu / g, and the coercive force is 0.92kOe. Take 30ml of double-sided grinding sludge and put it in a flask, add 150ml of absolute ethanol as a solvent, and vacuum distill at 80°C. After the liquid is evaporated to dryness, repeat the operation 5 times to obtain 25.32g of distilled powder. Distill the obtained distilled powder Put in a beaker. Prepare a dilute nitric acid aqueous solution with a concentration of 1vol.%, pour 127ml of dilute nitric acid solution into the oil sludge for ultrasonic cleaning, and keep stirring. During each cleaning process, the mixture is subjected to 10s ultrasonic treatment, and the above process is repeated 10 times. 120ml absolute ethanol sonicated once, 120ml acetone sonicated once. After removing the...

Embodiment 2

[0028] Nd in the sintered NdFeB sludge waste from double-sided grinding ② No. 2 Fe 14 Phase B and Nd 2 o 3 Phase, the rare earth content is 32.61%, the carbon content is 1.56%, the oxygen content is 4.40%, the saturation magnetization is 108.88emu / g, and the coercive force is 0.80kOe. Take 30ml of double-sided grinding sludge and put it in a flask, add 300ml of absolute ethanol as a solvent, and vacuum distill at 100°C. After the liquid is evaporated to dryness, repeat the operation 10 times to obtain 23.84g of distilled powder. Distill the obtained distilled powder Put in a beaker. Prepare a dilute nitric acid aqueous solution of 5vol.% concentration, pour 120ml of dilute nitric acid solution into the oil sludge for ultrasonic cleaning, and keep stirring, carry out 120s ultrasonic treatment to the mixture during each cleaning process, repeat the above process 15 times, and obtain the product using 120ml absolute ethanol was ultrasonicated 5 times, and 120ml acetone was ul...

Embodiment 3

[0031] Nd in the sintered NdFeB sludge waste from double-sided grinding ② No. 2 Fe 14 Phase B and Nd 2 o 3 Phase, the rare earth content is 32.61%, the carbon content is 1.56%, the oxygen content is 4.40%, the saturation magnetization is 108.88emu / g, and the coercive force is 0.80kOe. Take 30ml of double-sided grinding oil sludge and put it in a flask, add 240ml of absolute ethanol as a solvent, and vacuum distill at 90°C. After the liquid is evaporated to dryness, repeat the operation 8 times to obtain 24.20g of distilled powder. Distill the obtained distilled powder Put in a beaker. Prepare a dilute nitric acid aqueous solution of 3vol.% concentration, pour 121ml of dilute nitric acid solution into the oil sludge for ultrasonic cleaning, and keep stirring, carry out 60s ultrasonic treatment to the mixture during each cleaning process, repeat the above process 12 times, and obtain the product using 120ml absolute ethanol was ultrasonicated 3 times, and 120ml acetone was u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com