Steel sheet for hot stamping, manufacturing method thereof, and hot stamped formed body

一种制造方法、热冲压的技术,应用在热冲压用钢板及其制造、以及热冲压成型体领域,能够解决附着在加热炉内、钢板强度高、钢板强度下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

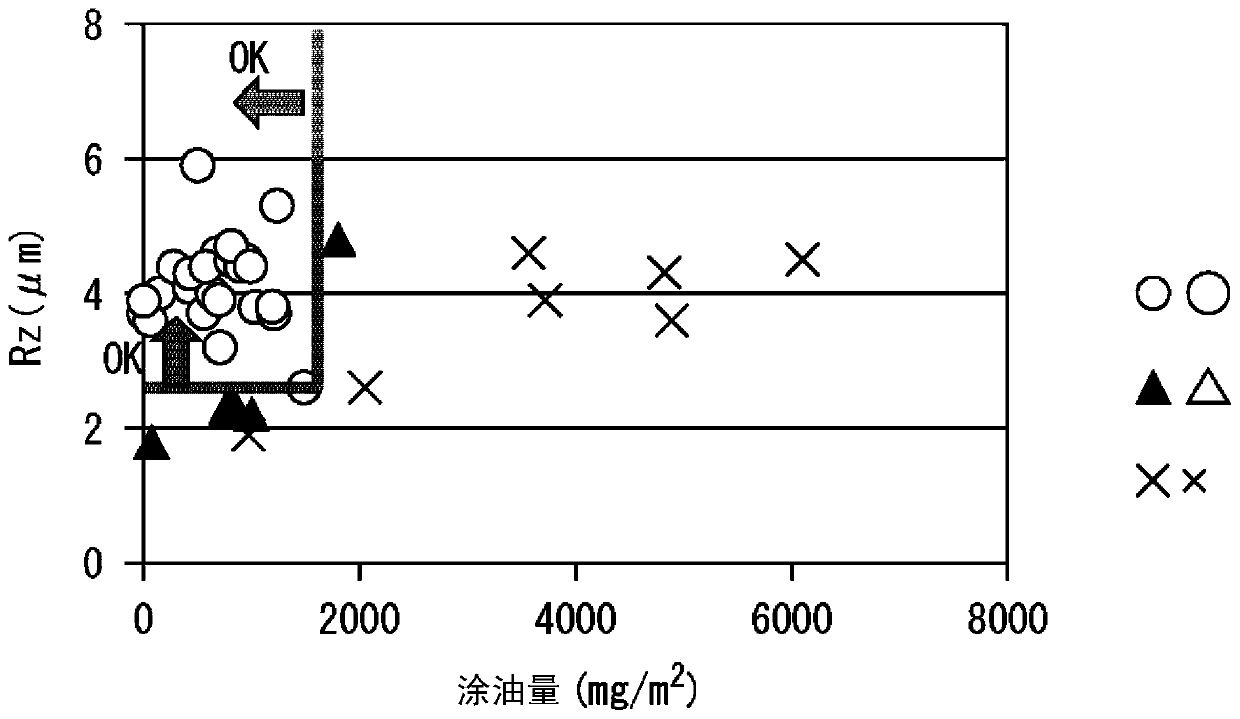

[0147] The amount of oiling can be measured by any method as long as it can be measured, but the inventors of the present invention measured it by the following method. First, the steel plate coated with the antirust oil was cut into 150 mm squares, and then a tape was attached so that an area of 100 mm×100 mm was exposed. Then, the weight of the oiled and sealed steel sheet (including the weight of the strip) is measured in advance. Next, degreasing was performed by wiping off the antirust oil on the surface of the steel plate with a cloth containing acetone, the weight of the degreased steel plate was measured, and the amount of oil applied per unit area was calculated by comparing the weights before and after degreasing. Each steel plate was carried out at 3 places, and the average value of the coating amount was taken as the oil coating weight of each steel plate.

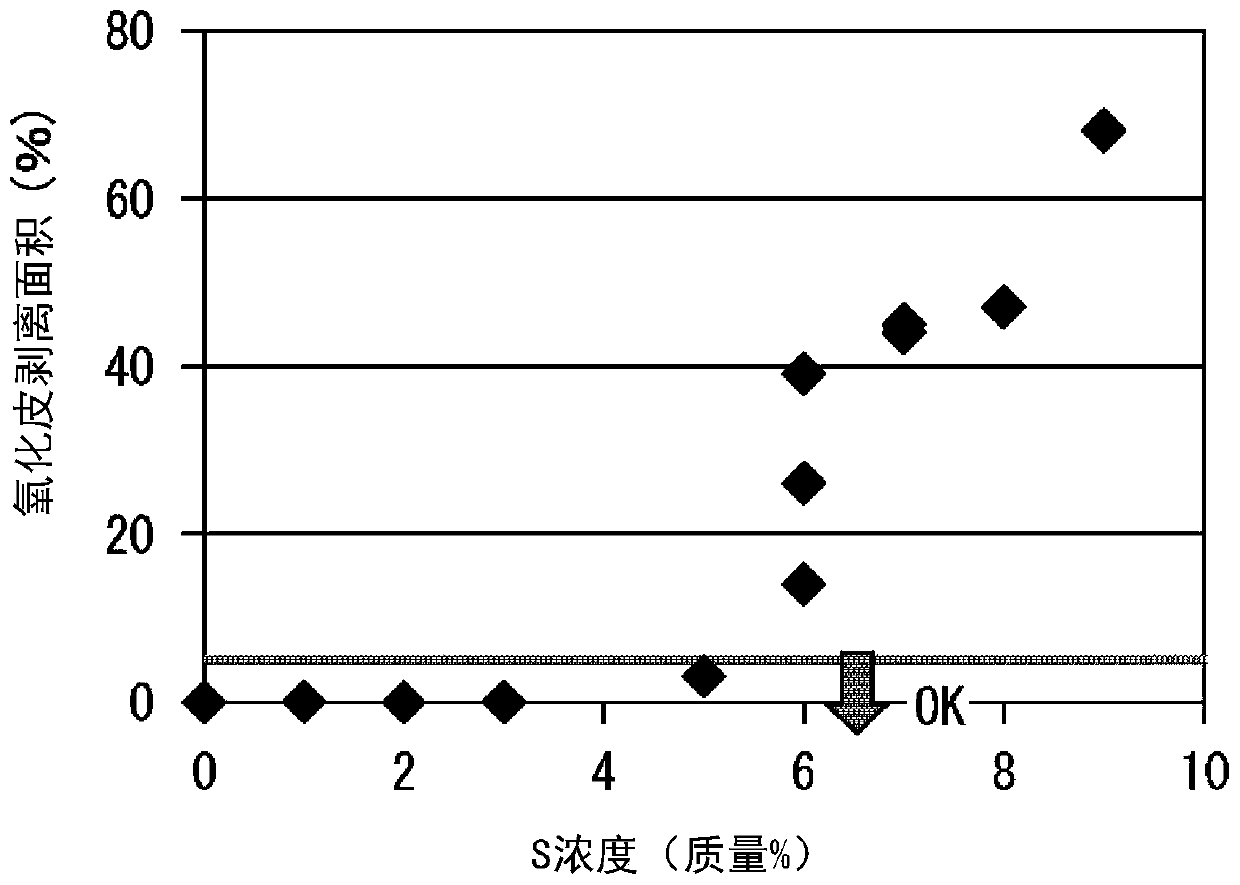

[0148] It is preferable to limit the S content contained in the antirust oil to 5% by mass or less. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com