Apparatus for manufacturing shadow mask using laser patterning and method for manufacturing shadow mask using laser patterning

A shadow mask and patterning technology, which is applied in the manufacture/processing of organic light-emitting devices, manufacturing tools, laser welding equipment, etc., can solve the problems of mask depression, small shadow mask thickness, difficulty in controlling and processing metal films, etc. Achieve the effect of simplifying the manufacturing process, reducing the time spent, preventing the use and elimination of harmful chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

best mode

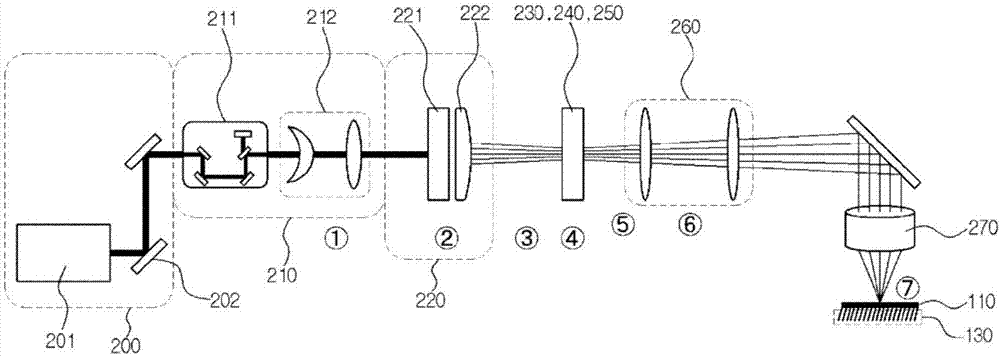

[0049] The present invention relates to a laser device that can use a mask projection optical system appropriately designed according to the size and gap of a desired pattern by directly forming a pixel-shaped pattern on a base without going through a series of processes. Create a shadow mask.

[0050] In addition, the present invention relates to a method of manufacturing a shadow mask by forming a fine mask pattern on a submount using a laser, which can simplify the manufacturing process by photolithography, as compared with the prior art method. Therefore, it is possible to reduce the time it takes to manufacture the shadow mask compared to the method of manufacturing the mask in the related art.

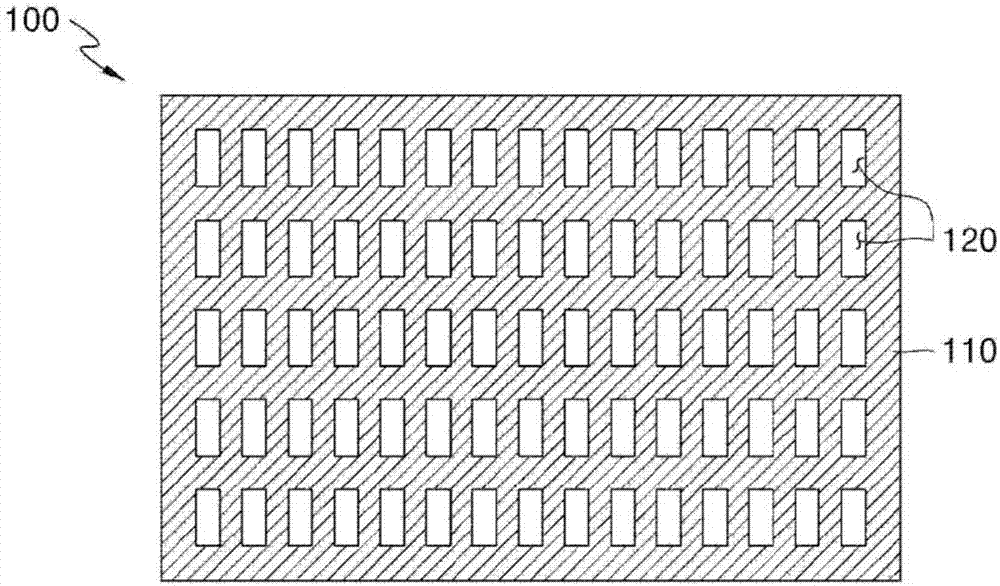

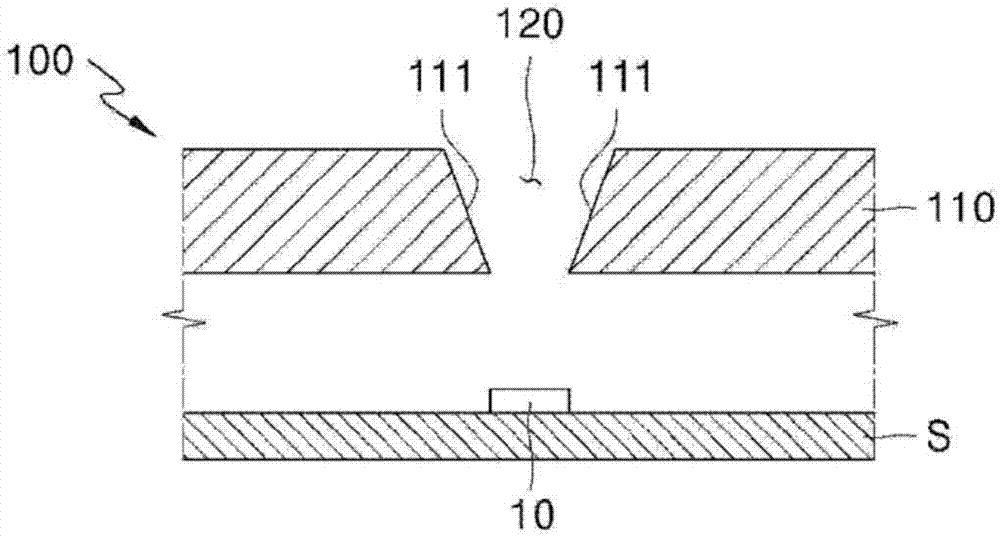

[0051] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. figure 1 is a plan view of a shadow mask fabricated by a method according to an embodiment of the invention, figure 2 yes figure 1 A cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com