Steel Sheet For Hot Pressing And Method For Producing Same

A steel sheet for hot pressing and a manufacturing method technology, which are applied in manufacturing tools, chemical instruments and methods, metal rolling, etc., can solve the problems of easy disappearance of zinc coating and oxidation of steel surface, and achieve the goal of inhibiting oxidation and disappearance of zinc coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

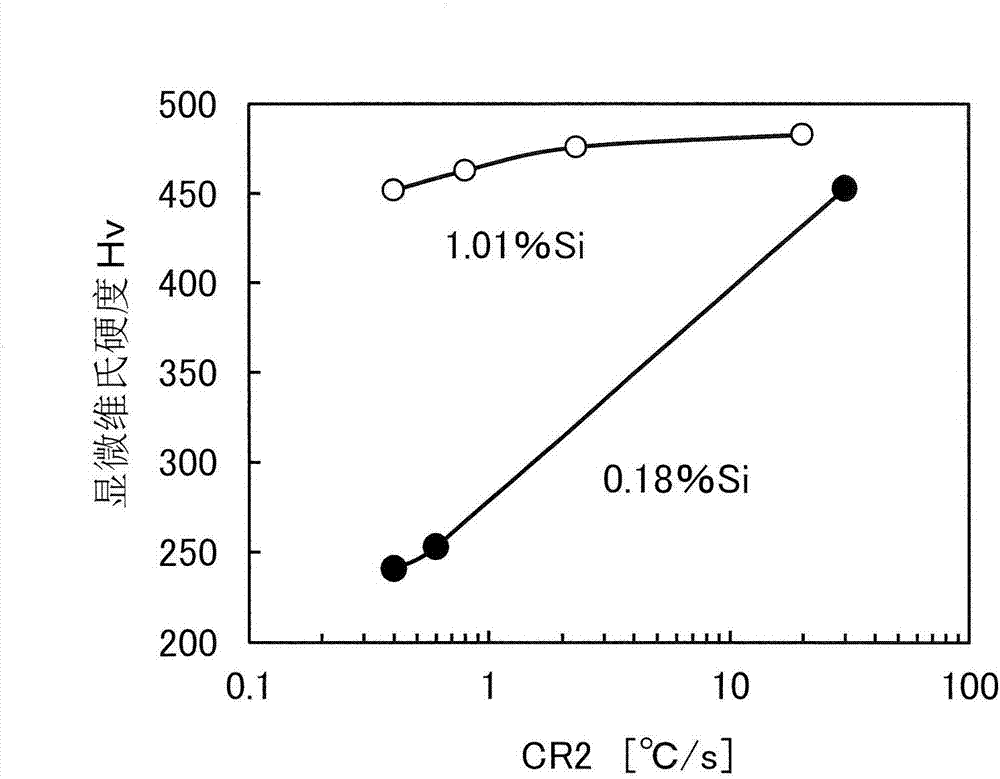

[0113] In Example 1, the influence of the amount of Si in the steel sheet on the "relationship between the cooling rate during hot pressing and the hardness of the steel sheet" was examined.

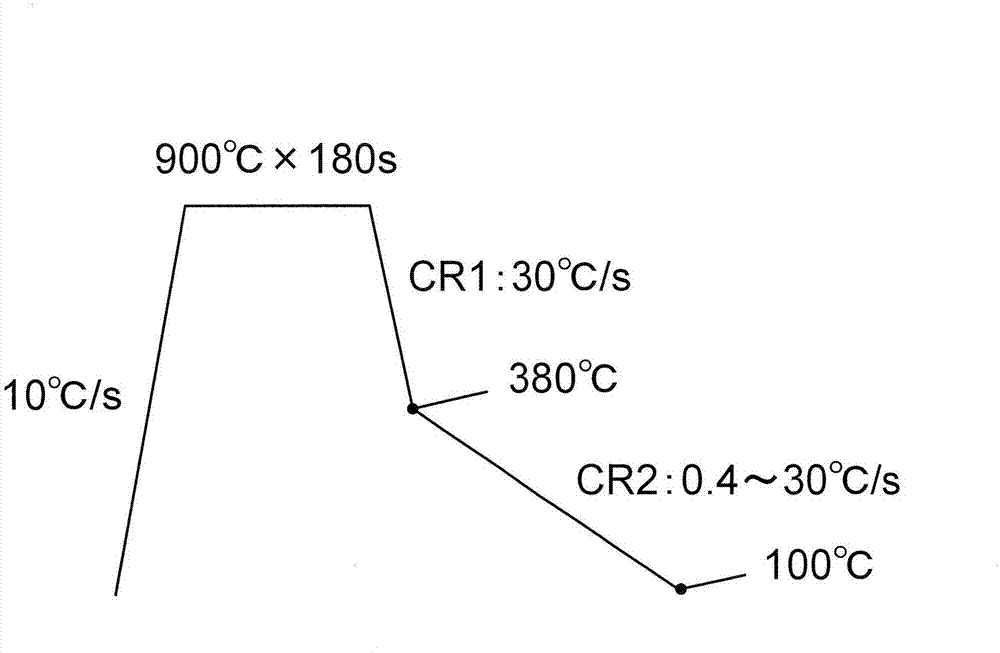

[0114] A 50 kg steel ingot satisfying the composition shown in Table 1 was melted, heated to 1150° C., and rough rolled to produce a 30 mm thick steel plate. In addition, "sol.Al amount" in Table 1 means the Al amount prescribed|regulated in this invention. In addition, in Table 1 and Table 3 described later, "-" is indicated in the column of an element not added. The said steel plate was heated again to 1250 degreeC, it hot-rolled, and the hot-rolled steel plate of thickness 2.3mm was produced. At this time, the finishing temperature is 920°C, and after the hot rolling, it is water-cooled to 650°C, and then put into a holding furnace with an inner temperature of 650°C for 30 minutes in order to simulate the cooling state after coiling in the actual production line. . After the holdin...

Embodiment 2

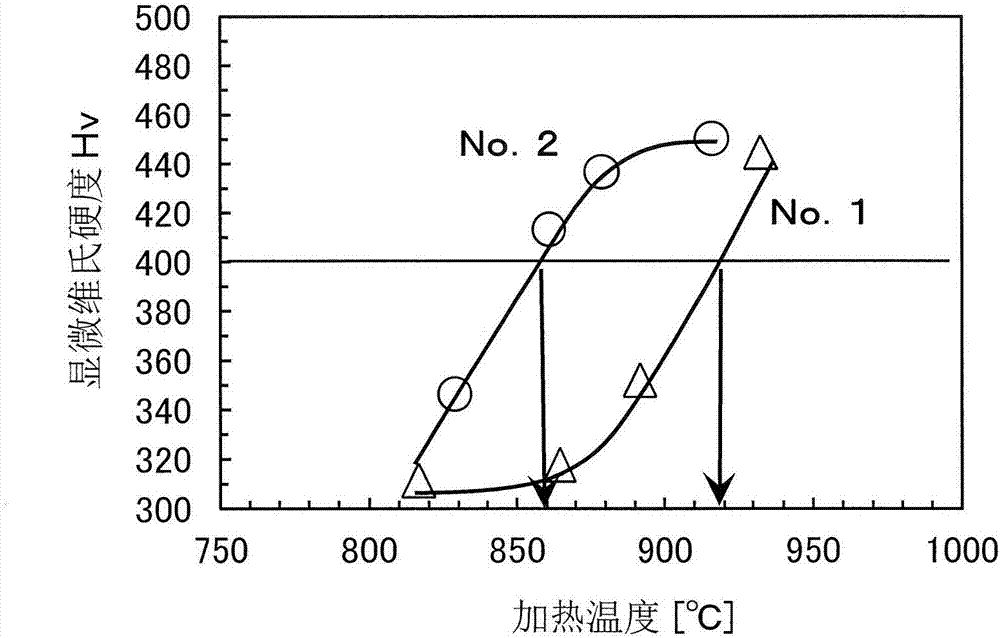

[0121] In Example 2, the influence of the dislocation density of the steel sheet on the heating temperature during hot pressing was examined. Specifically, the influence of the dislocation density of the steel sheet on the heating temperature required to ensure a strength equal to or higher than a predetermined value by hot pressing, that is, the minimum heating temperature was considered.

[0122] For Nos. 1 and 2 in Table 2, cold-rolled steel sheets were prepared as follows. Under the same conditions as in Example 1, a hot-rolled steel sheet having a thickness of 3.2 mm as the steel type A shown in Table 1 was produced, and after removing scale generated during hot rolling with hydrochloric acid, it was implemented at the cold rolling rate shown in Table 2. Cold rolled steel sheets with various dislocation densities were prepared. In addition, for Nos.3 to 7 in Table 2, hot rolling was carried out at a finishing temperature of 920° C., and coiling was carried out at a coili...

Embodiment 3

[0135] In Example 3, the effects of the production conditions of the steel sheet on the microstructure and dislocation density, and the resulting steel sheet tensile strength and minimum heating temperature were examined.

[0136] Use steel blocks of steel type AA that are basically the same composition as steel type A in Table 1 or steel type C in Table 3, and steel blocks of steel types C~J in Table 3. In actual production equipment, the heating temperature is 1200 ℃, hot-rolled at the finishing temperature shown in Table 4, and coiled at the coiling temperature shown in Table 4, to manufacture steel strips of hot-rolled steel sheets with various thicknesses shown in Table 4, wherein the The composition of steel type AA contains C: 0.22%, Si: 1.14%, Mn: 2.25%, P: 0.010%, S: 0.005%, sol.Al: 0.038%, N: 0.0035%, B: 0.0022%, and Ti: 0.021%, and the balance is iron and unavoidable impurities. No. 1 in Table 4 is a hot-rolled steel sheet.

[0137] After the hot rolling, pickling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com