Bi-directional motion telescopic mechanical arm

A two-way motion and robotic arm technology, applied in the field of robotic arms, can solve the problems of limited working environment and fewer robots with flexible arms, and achieve the effects of wide development range, light and compact overall structure, and exquisite control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

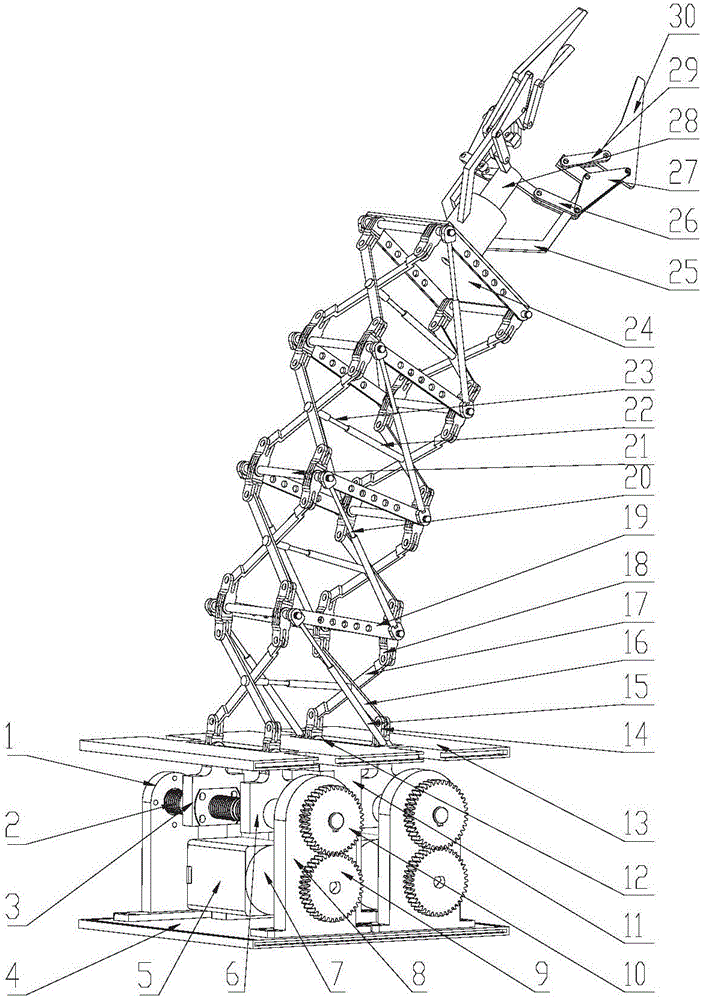

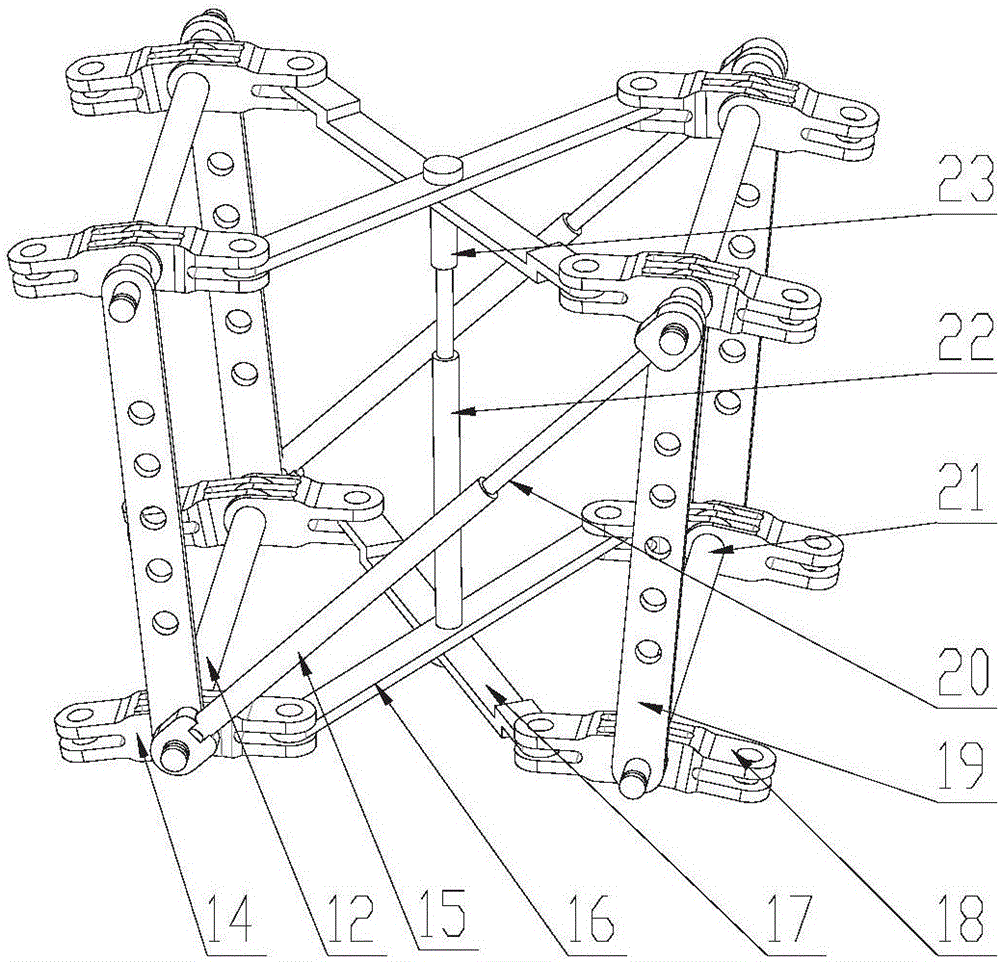

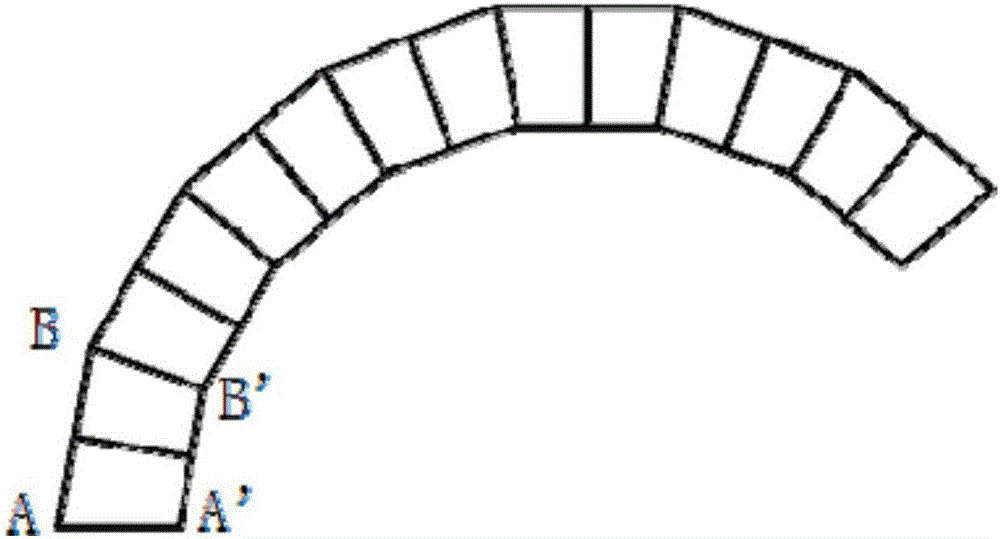

[0028] figure 1 Is a schematic diagram of the structure of the present invention; figure 1 As shown, the two-way motion telescopic mechanical arm provided by the present invention includes a base, a control system, an intermediate support plate 13, a mechanical arm, an upper support plate 24, and a manipulator. The control system is installed in the base, and the intermediate support plate 13 is installed above the base, the robot arm is installed on the middle support plate 13 and connected to the control system, the upper support plate 24 is installed at the end of the robot arm, and the robot arm is installed on the upper support plate 24 on. The control system drives the robot arm to produce lateral bending or telescopic deformation, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com