Automatic transferring device of carbon fiber composite material production line and transferring method of automatic transferring device

A composite material and transfer device technology, applied in transportation and packaging, manipulators, program-controlled manipulators, etc., can solve the problems of insufficient stability of materials, large turnover errors, and complicated coordination, so as to improve the turnover accuracy, improve production efficiency, and move quickly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The core of the present invention is to provide a 180-degree overturning device, which is used for automatic overturning of carbon fiber parts during the automatic transfer process of a carbon fiber composite material production line, and the overturning device can realize automatic overturning of parts.

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

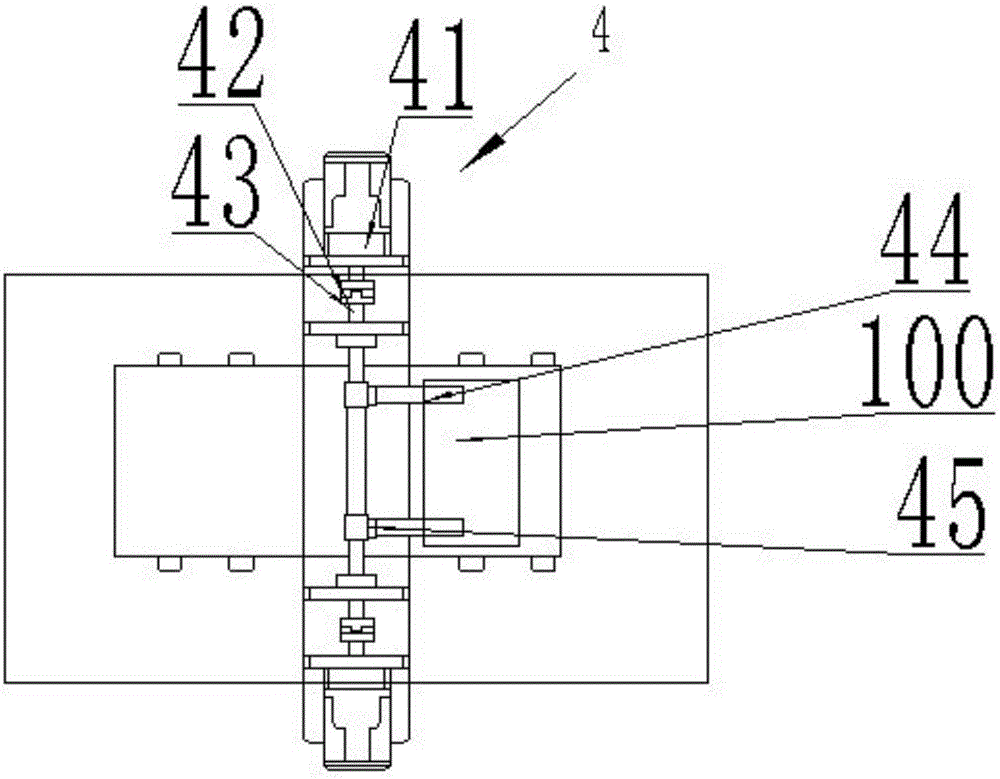

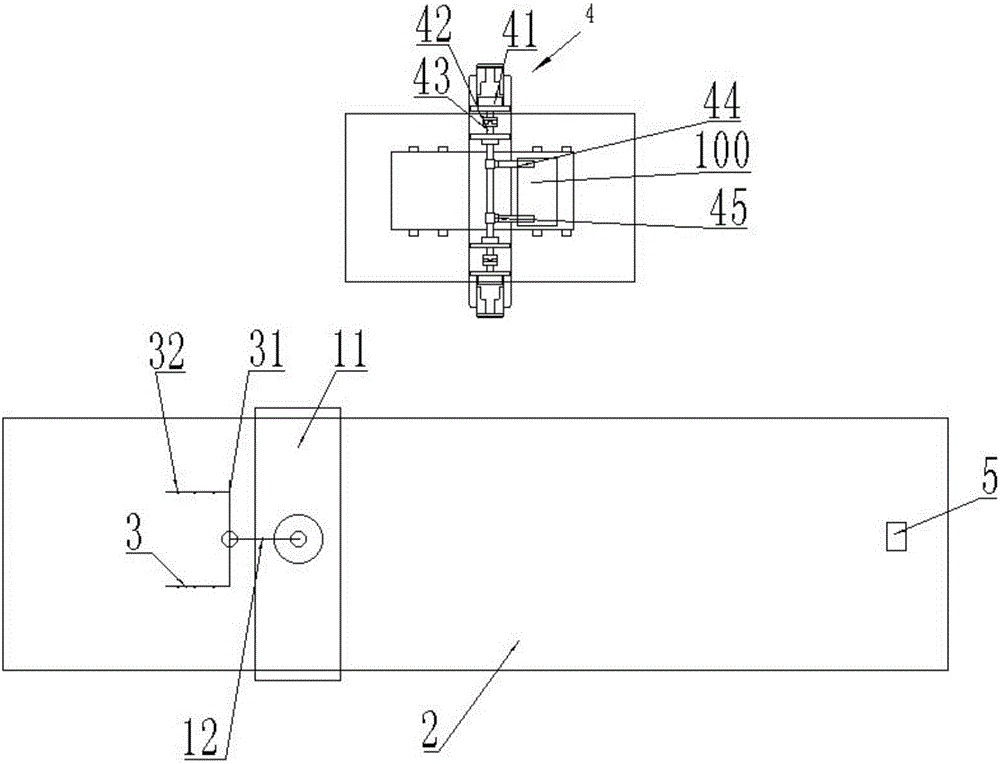

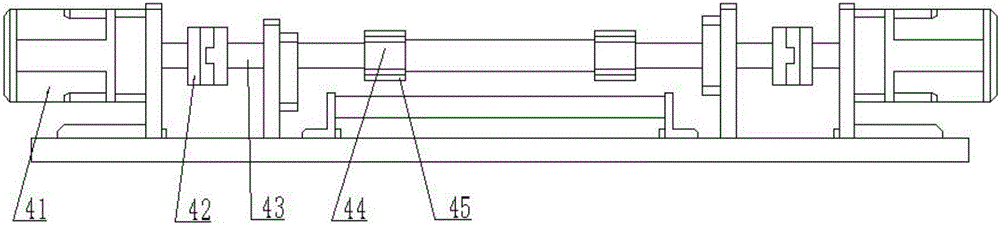

[0037] see Figure 1-6 , an automatic transfer device for a carbon fiber composite material production line, including a traveling mechanism (1), a horizontal moving track (2), a vacuum suction cup set (3) and a turning table (4); the traveling mechanism (1) includes a walking base (11 ) and the robot (12); the walking base (11) walks on the horizontal moving track (2), the robot (12) is fixed on the walking base (11), and the free end of the robot (12) is equipped with a vacuum suction cup group (3), The vacuum suction cup group (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com