Sulfur injection method for continuous reforming apparatuses

A reforming device, sulfur content technology, applied in the field of petrochemical industry, can solve the problems of not mentioning the need for sulfur injection, potential safety hazards, no pre-passivation sulfur injection speed, etc., and achieve the effect of inhibiting metal catalytic coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

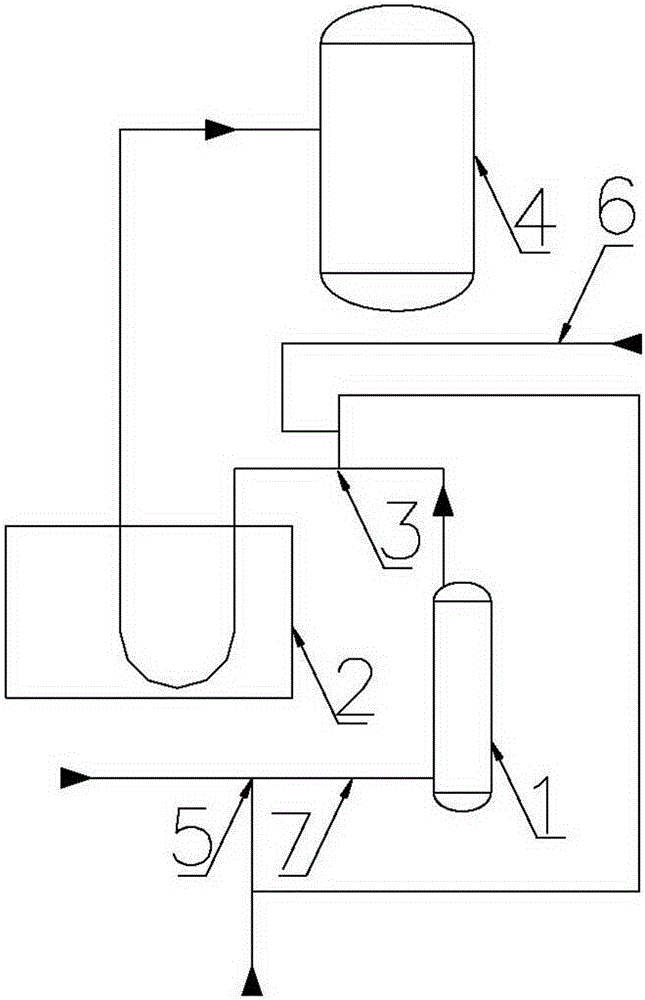

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, a method for injecting sulfur into a continuous reforming unit includes replacing the reaction system packed with a platinum reforming catalyst with hydrogen-containing gas. When the circulating hydrogen concentration in the reaction system reaches 70-99.5% (volume percentage), Establish hydrogen-containing gas circulation, then the temperature of the reaction system rises, when the reactor inlet temperature rises to 300-480°C, preferably at a certain temperature point of 370-460°C, open the gap between the reforming mixed feed heat exchanger 1 and the feed heating furnace 2 The pre-injection sulfur inlet 3 injects sulfide, and the catalyst loading amount in the first reactor 4 is used as the base, and the sulfur injection amount is determined according to the catalyst sulfur content of 100-200 μg / g, and the pre-injection sulfur is set acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com