Device for inhibiting coking of hydrocarbon-like steam cracking device and quenching boiler

A cracking device and quenching boiler technology, applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problems of polluting downstream products, cumbersome operating conditions, and industrial impossibility, etc., to achieve extended operating cycle, simple operation, and efficient operation method simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

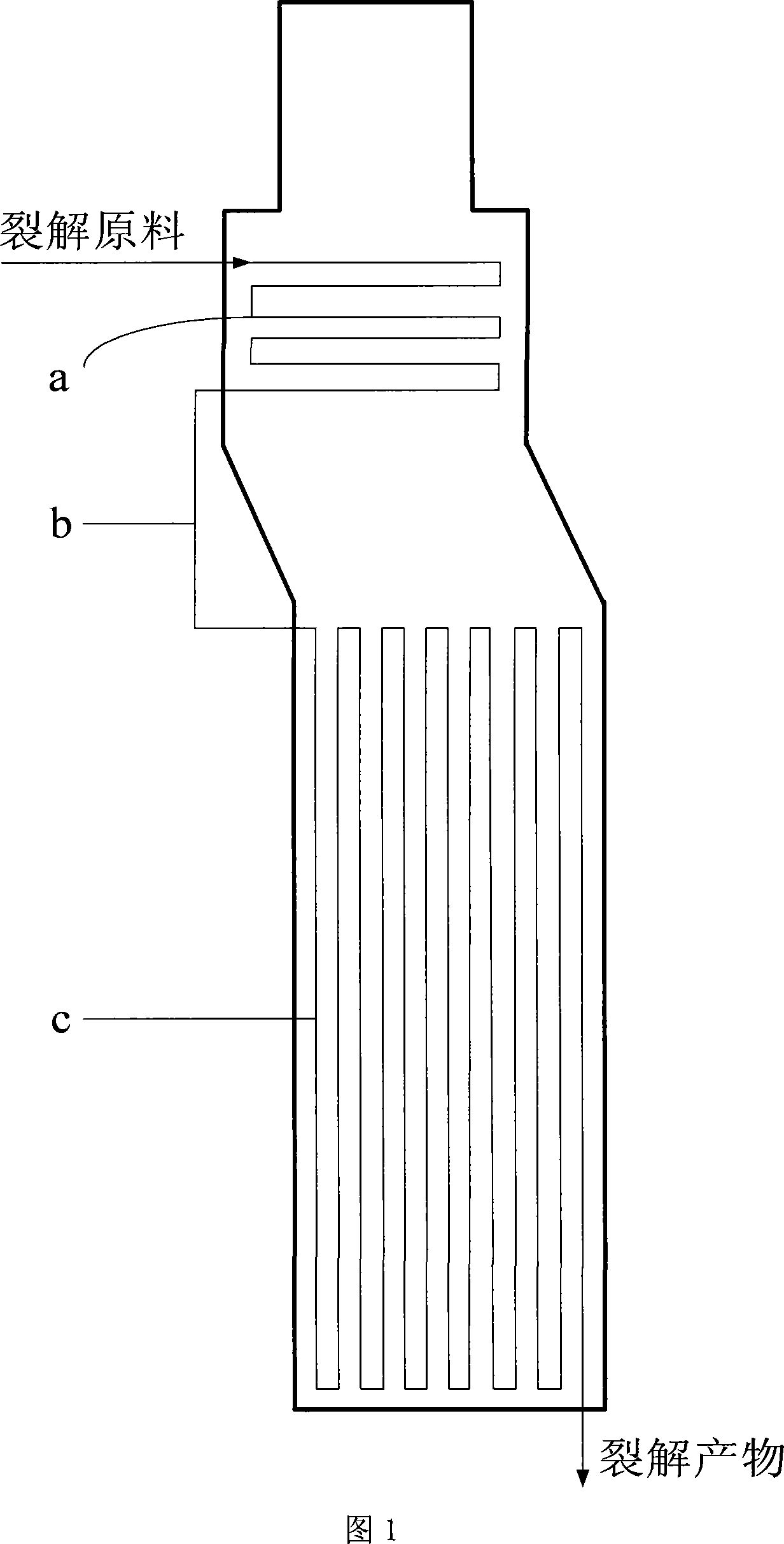

[0038] Embodiment 1 and embodiment 2 are the method that industrial cracking furnace is processed.

[0039] Example 1

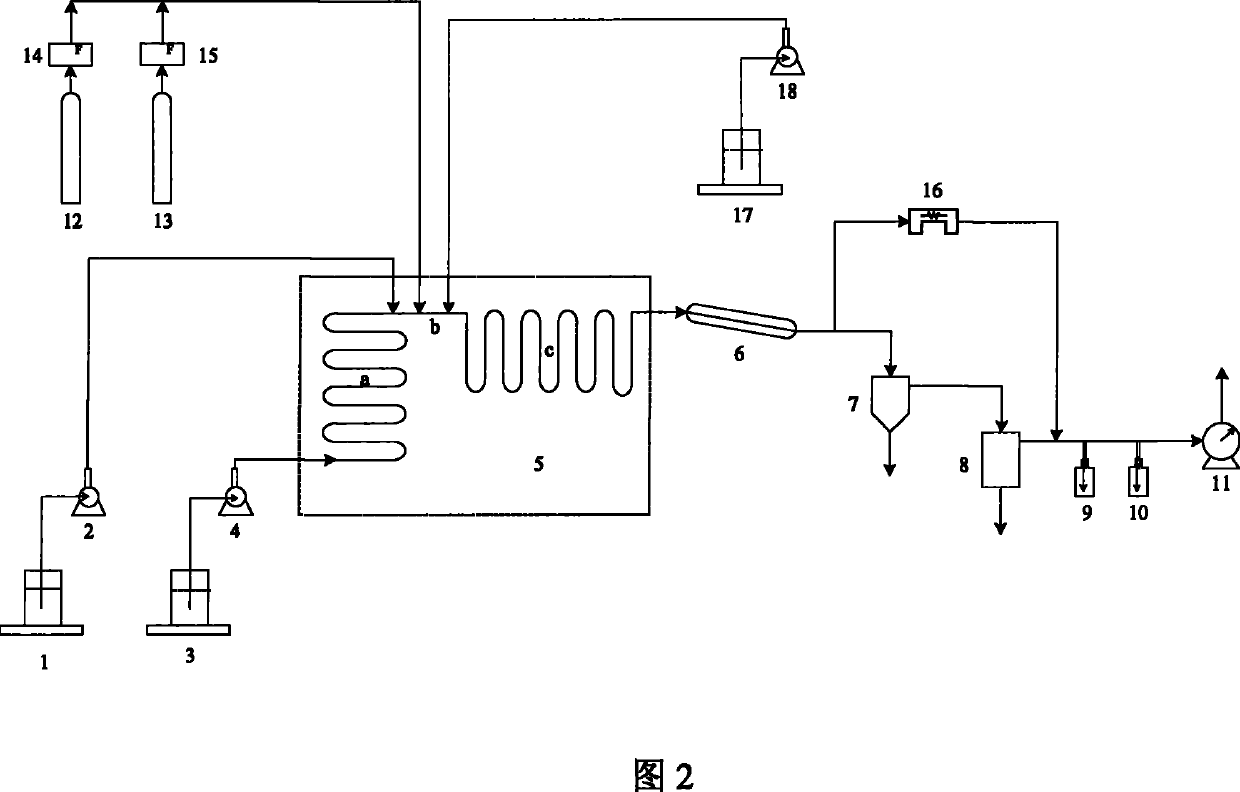

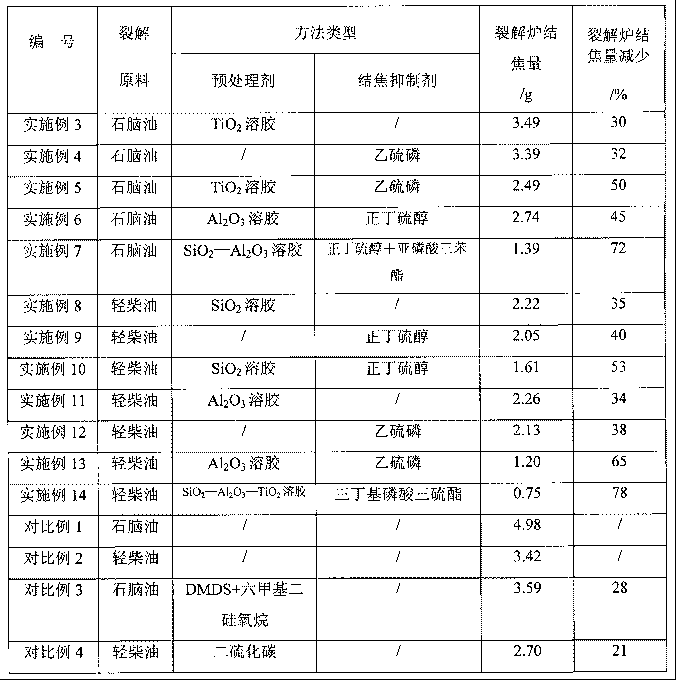

[0040] SiO 2 The mass concentration is 20%, and the neutral silica sol that pH is 6.5~7.5 is diluted with water to be pure oxide mass concentration and is the silica sol aqueous solution of 1.0%. ~850°C, under the operating pressure of 0.4Mpa, inject the diluted silica sol aqueous solution into the cracking furnace from the convection section of the cracking furnace under the accompaniment of carrier gas water vapor. The sol aqueous solution accounts for 18wt% of the total weight of the carrier gas. The injection time is 3 hours; Then, during the oiling operation of the cracking furnace, n-butanethiol is continuously injected into the cracking furnace from the convection section of the cracking furnace under the companionship of the carrier gas steam, and the n-butylmercaptan accounts for the total weight of the carrier gas 16wt%, the weight ratio of carri...

Embodiment 2

[0042] Set the solid content to 20%, SiO 2 / Al 2 o 3 =8, PH is that the aluminum silicate sol of 3~4 is diluted with water to be the SiO that pure oxide mass concentration is 2.0% 2 -Al 2 o 3 Aqueous sol solution, in which SiO 2 : Al 2 o 3 =8: 1 (molar ratio), during the thermal preparation after the cracking furnace burnt, the outlet temperature of the cracking furnace is 700~850 ℃, under the operating pressure of 0.3Mpa, the diluted SiO 2 -Al 2 o 3 The sol aqueous solution is injected into the cracking furnace from the spanning section of the cracking furnace under the companionship of the carrier gas water vapor. The sol aqueous solution accounts for 10wt% of the carrier gas gross weight, and the injection time is 2 hours; Phosphorus compound tributyl phosphate trithioester (wherein the atomic molar ratio of sulfur element to phosphorus element is S:P=3:1), accompanied by carrier gas and water vapor, is continuously injected from the spanning section of the crackin...

Embodiment 3

[0047] To simulate the SRT-III cracking furnace, when the outlet temperature of the cracking furnace is 800°C, the TiO 2 TiO with a mass concentration of 30% 2 The sol was diluted with water to obtain TiO with a mass concentration of 0.5% pure oxide 2 The sol aqueous solution is injected into the cracking furnace from the spanning section of the cracking furnace for pretreatment, the treatment time is 1 hour, and the injection rate is 200g / h; then, naphtha cracking is carried out when the outlet temperature of the cracking furnace is 840°C. The physical properties of raw naphtha are: distillation range 48-211°C, specific gravity D 15.6 0.7287, sulfur content 165PPM; cracking conditions: cracking temperature 840°C, feed oil 800g / h, water 400g / h, residence time 0.37 seconds, water-oil ratio 0.5, reaction time 6 hours. The amount of coking in the simulated cracking furnace is 3.49g, which is 30% less than that of the untreated furnace tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com