Self-decoking coating as well as preparation method and application thereof

A coating and self-cleaning technology, which is applied in coatings, metal material coating processes, solid-state diffusion coatings, etc., can solve the problems of lack of inhibition methods for condensation coking and free radical coking, decline in the protective effect of composite coatings, co-silicon-aluminum coatings, etc. Low permeation efficiency and other issues can be achieved to shorten the preparation time, good anti-coking effect, and inhibit inward migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

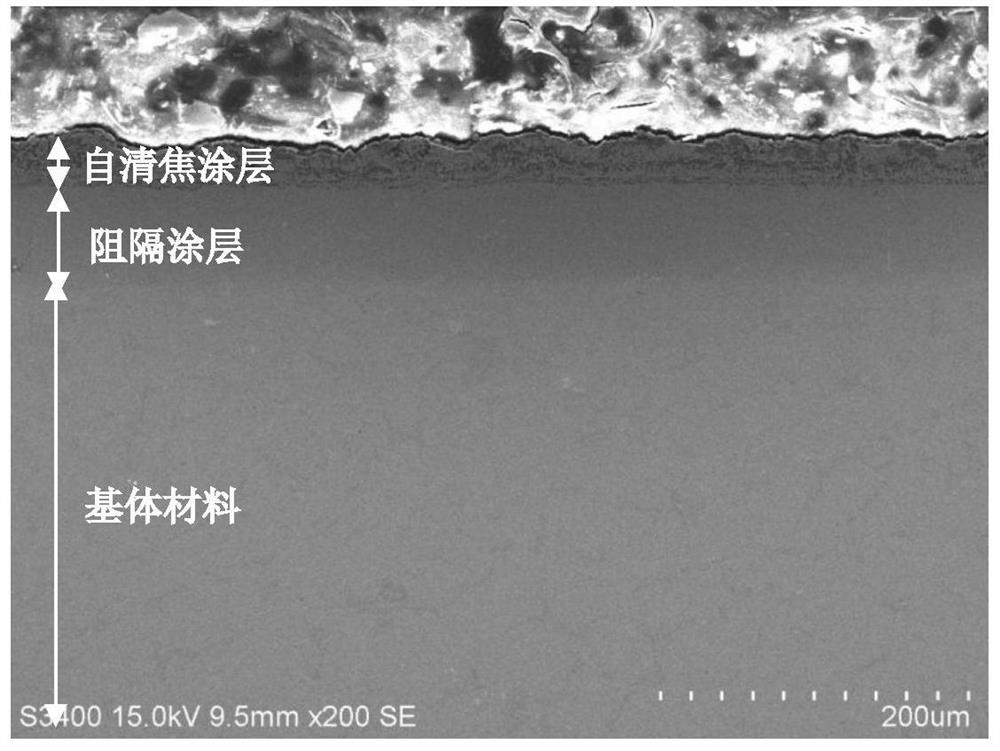

[0048] Take a Cr25Ni35 substrate sample in Comparative Example 1, embed it in an inert container filled with a barrier coating penetrating agent, compact the substrate sample and the barrier coating penetrating agent material, and seal the inert container. The composition of the barrier coating penetrating agent is calculated by mass percentage: 22% of chromium powder, 0.5% of chromium fluoride, 5% of silicon powder, 1.0% of zirconium chloride, 3.0% of ammonium chloride, and 68.5% of aluminum oxide. Put the inert container into the muffle furnace for chemical heat treatment, raise the temperature in the muffle furnace from room temperature to 700°C at a rate of 10°C / min, and then from 700°C to 1030°C at a rate of 5°C / min, and keep the temperature constant 7h. After cooling, remove the penetrating agent powder, grind and polish, and control the coating thickness.

[0049] Embed the ground and polished base material in an inert container containing the penetrating agent for the...

Embodiment 2

[0052] Take a Cr25Ni35 substrate sample in Comparative Example 1, embed it in an inert container filled with a barrier coating penetrating agent, compact the substrate sample and the barrier coating penetrating agent material, and seal the inert container. The composition of the barrier coating penetration agent is calculated by mass percentage: 19% of chromium powder, 0.1% of chromium fluoride, 2% of silicon powder, 0.1% of zirconium oxide, 3.8% of ammonium chloride, and 75% of aluminum oxide. Put the inert container into the muffle furnace for chemical heat treatment, raise the temperature in the muffle furnace from room temperature to 700°C at a rate of 5°C / min, and then from 700°C to 1080°C at a rate of 1°C / min, and keep the temperature constant 9h. After cooling, remove the penetrating agent powder, grind and polish, and control the coating thickness.

[0053] Embed the ground and polished base material in an inert container containing the penetrating agent for the clear...

Embodiment 3

[0056] Take a Cr25Ni35 substrate sample in Comparative Example 1, embed it in an inert container filled with a barrier coating penetrating agent, compact the substrate sample and the barrier coating penetrating agent material, and seal the inert container. The composition of the barrier coating penetration agent is calculated by mass percentage: 20% of chromium powder, 0.3% of chromium fluoride, 3% of silicon powder, 0.5% of zirconium chloride, 1.3% of ammonium chloride, and 74.9% of aluminum oxide. Put the inert container into the muffle furnace for chemical heat treatment, raise the temperature in the muffle furnace from room temperature to 700°C at a rate of 10°C / min, and then from 700°C to 1050°C at a rate of 5°C / min, keep the temperature constant 4h. After cooling, remove the penetrating agent powder, grind and polish, and control the coating thickness.

[0057] Embed the ground and polished base material in an inert container containing the penetrating agent for the cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com