Cracking furnace tube for inhibiting catalytic coking of hydrocarbon cracking furnace tube, and manufacturing method thereof

A hydrocarbon cracking furnace tube and a cracking furnace tube technology are applied to the cracking furnace tube and its manufacturing field for inhibiting coking during the cracking of petroleum hydrocarbons, and can solve the problems of weak binding force, affecting the performance of an oxide film protective layer, and being difficult to obtain. Achieve the effect of satisfying long-term use, inhibiting catalytic coking, and increasing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

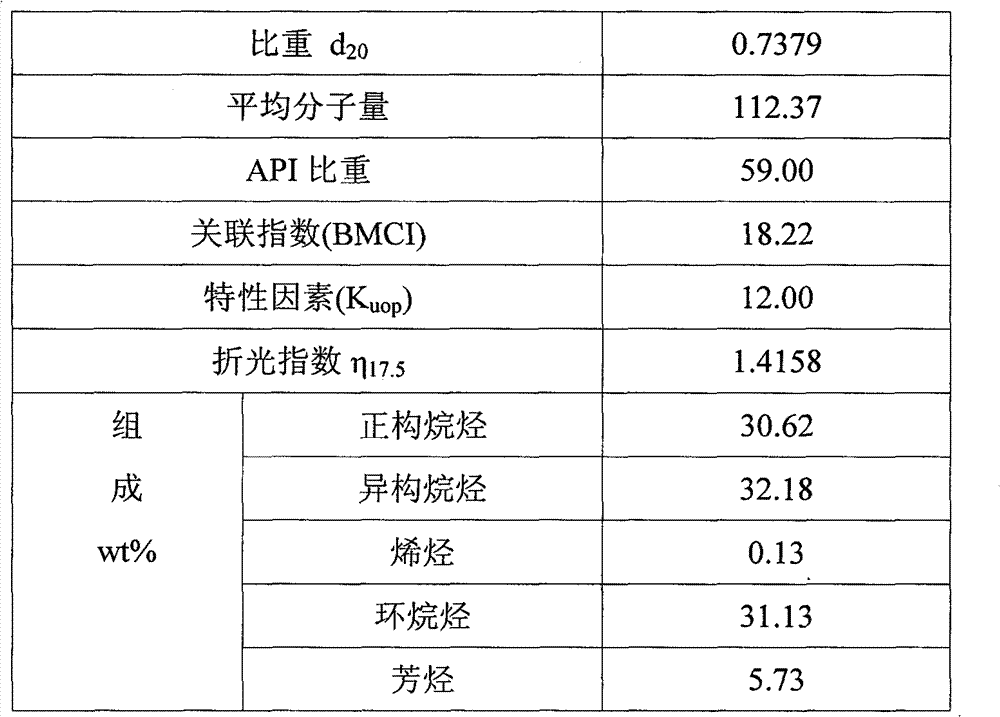

[0044] The inner surface of the 2520 nickel-chromium alloy furnace tube with a size of φ14×2×800 is bright and free of scale after machining, and the surface composition of the furnace tube is analyzed by X-ray energy dispersive spectrometer (Energy Dispersive Spectrometer, referred to as EDS). The results are shown in Table 1.

[0045] Use this furnace tube to carry out low oxygen partial pressure atmosphere treatment on a self-made laboratory device with a feed rate of 200g / h. Use H 2 、CH 4 and H 2 A gas mixture of O is used as a low oxygen partial pressure atmosphere treatment gas, where H 2 The volume percentage of O is adjusted between 0.6% and 1.2%, CH 4 8% by volume, the rest is H 2 , the flow rate of the mixed gas is 300mL / min. Specific steps are as follows:

[0046] (1) Let the furnace tube be at H 2 、CH 4 and H 2 In the atmosphere of O;

[0047] (2) Raise the temperature of the furnace tube to 600°C at a heating rate of 60°C / h, the heating process H 2 The...

Embodiment 2

[0070] The 2520 nickel-chromium alloy furnace tube in embodiment 1 is replaced with 2535 nickel-chromium alloy furnace tube, and the low oxygen partial pressure atmosphere treatment is carried out on the laboratory device in embodiment 1. Using pure H 2 As a low oxygen partial pressure atmosphere treatment gas, the whole treatment process, H 2 The volume percentage of O was kept at 1.2%, and the gas flow rate was 300ml / min. Specific steps are as follows:

[0071] (1) Let the furnace tube be at H 2 and H 2 In the atmosphere of O;

[0072] (2) Raise the furnace tube temperature to 650°C at a heating rate of 60°C / h;

[0073] (3) The furnace tube is kept at 650°C for 6 hours;

[0074] (4) Raise the furnace tube temperature to 850°C at a heating rate of 30°C / h;

[0075] (5) The furnace tube is kept at a constant temperature of 850°C for 20 hours;

[0076] After cooling, the surface composition was analyzed with a scanning electron microscope and an energy dispersive spectro...

Embodiment 3

[0084]The 2520 nickel-chromium alloy furnace tube in Example 1 was replaced with a 3545 nickel-chromium alloy furnace tube, and the low oxygen partial pressure atmosphere treatment was carried out on the laboratory device in Example 1. Use H 2 、C 2 h 6 and H 2 A gas mixture of O is used as a low oxygen partial pressure atmosphere treatment gas, where H 2 The volume percentage of O is 0.6%~1.2%, C 2 h 6 2% by volume, the rest is H 2 , the flow rate of the mixed gas is 300ml / min. Specific steps are as follows:

[0085] (1) Let the furnace tube be at H 2 、C 2 h 6 and H 2 In the atmosphere of O;

[0086] (2) Raise the temperature of the furnace tube to 750°C at a heating rate of 60°C / h, the heating process H 2 The volume percentage of O is 1.2%;

[0087] (3) The furnace tube is kept at 750°C for 6 hours, and the constant temperature process is H 2 The volume percentage of O is 1.2%;

[0088] (4) Raise the temperature of the furnace tube to 950°C at a heating rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com