Surface color treatment of alloys with micro-arc oxidation process

A surface treatment, aluminum alloy surface technology, applied in the field of micro-arc oxidation treatment process, can solve the problems of inefficiency, undesired color and dissatisfaction on the treated surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1: Black MAO treatment on aluminum alloy

[0028] Samples made from commercial grade aluminum alloy 7075 were used in these experiments. By way of example, Figure 6A Table 600 in shows the chemical composition of aluminum alloy 7075. In one example embodiment, those skilled in the art will appreciate that other aluminum alloys comprising at least 90% aluminum will also be suitable for use in these experiments.

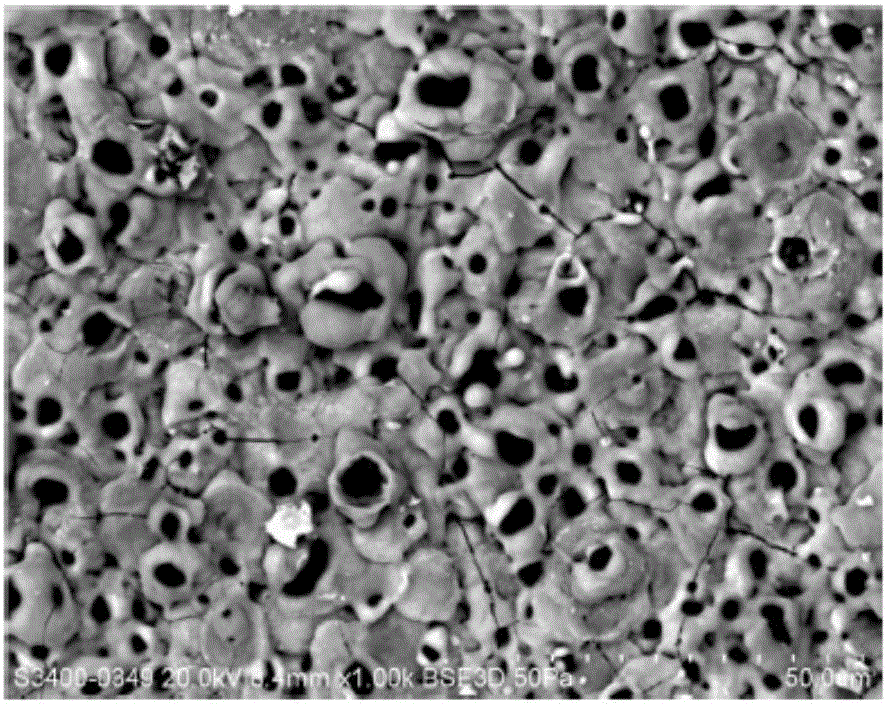

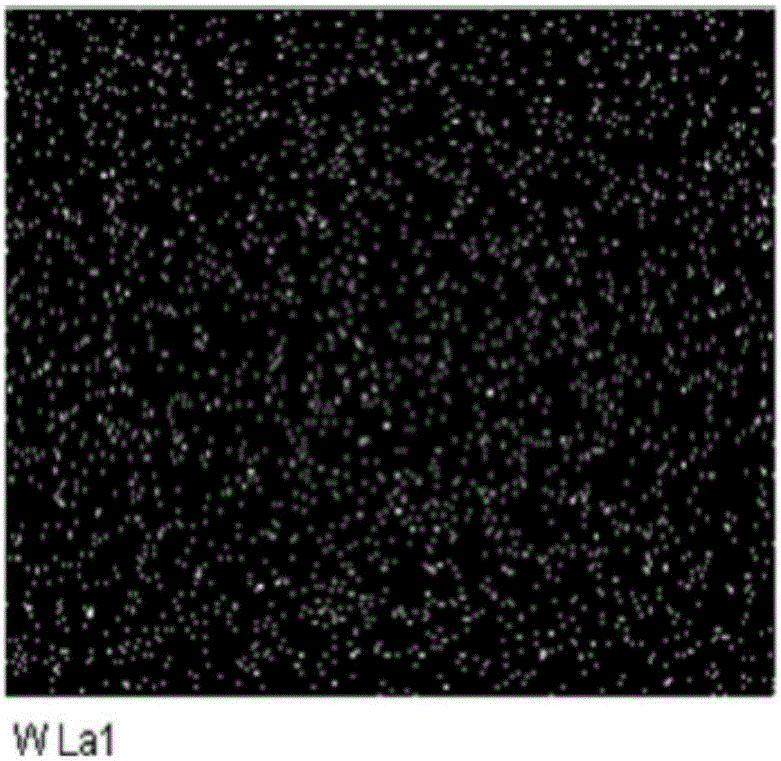

[0029] Aluminum alloy samples were treated using the micro-arc oxidation (MAO) method. First, the electrolyte for MAO treatment was prepared by dissolving 10–30 g / L silicate and 3–6 g / L hydroxide into deionized (DI) water in a stainless steel bath. Subsequently, an additive of 8-40 g / L tungstate is added to the electrolyte. With 0.03-0.17A / cm 2 A current with a current density and a pulse frequency of 500-2600 Hz is applied to the aluminum alloy immersed in the electrolyte for a period of 100-720 seconds. A chemically and mechanically protective a...

example 2

[0042] Example 2: Black MAO treatment on magnesium alloy

[0043] Specimens made from commercial grade magnesium alloys AZ31B or AZ91D were used in these experiments. By way of example, Figure 6B Table 602 in shows the chemical composition of magnesium alloy AZ31B and magnesium alloy AZ91D. In one example embodiment, those skilled in the art will appreciate that other magnesium alloys comprising at least 90% magnesium will also be suitable for use in these experiments.

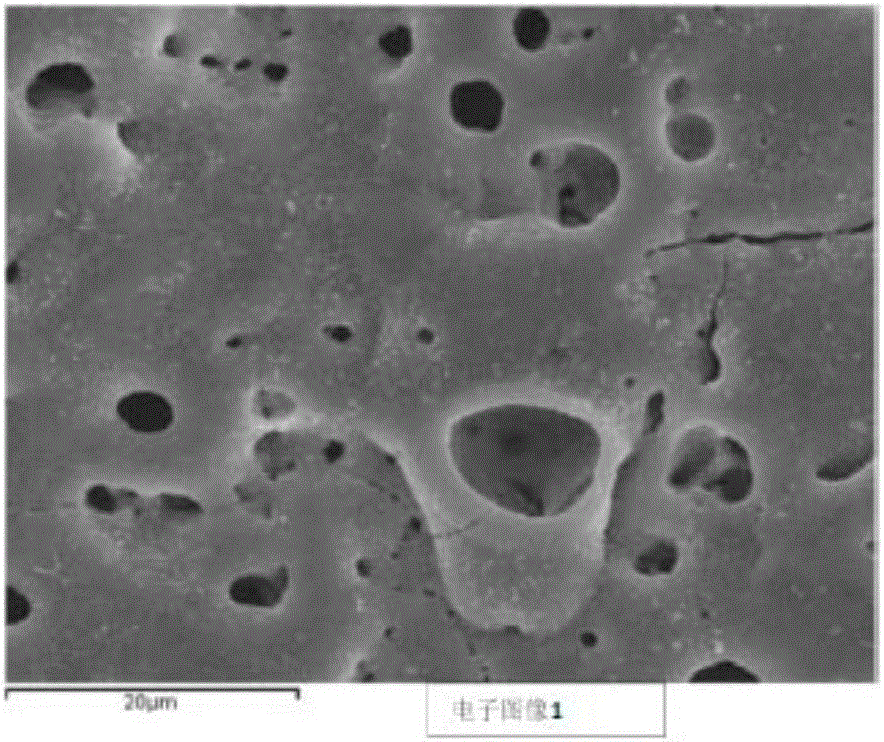

[0044] Magnesium alloy samples were processed using the MAO method. First, the electrolyte for MAO treatment was prepared by dissolving 20–30 g / L silicate, 5–20 g / L phosphate, and 3–6 g / L hydroxide into DI water in a stainless steel bath. Subsequently, add 5-10g / L glycerin, 0.5-2g / L tungstate and 5-15g / L TiO 2 Nanoparticles are added to the electrolyte. By way of example, the added TiO 2 The nanoparticles are rutile titanium dioxide with a particle size of 30 nm. With 0.03-0.17A / cm 2 A current with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com