Guardrail used for underground complex and having submersion-resistant water drainage function

A complex and guardrail technology, applied to drainage structures, sewer pipe systems, water supply devices, etc., can solve the problems of personal and property injury, harm, life-threatening, etc., achieve industrialized dismantling convenience, increase escape time, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

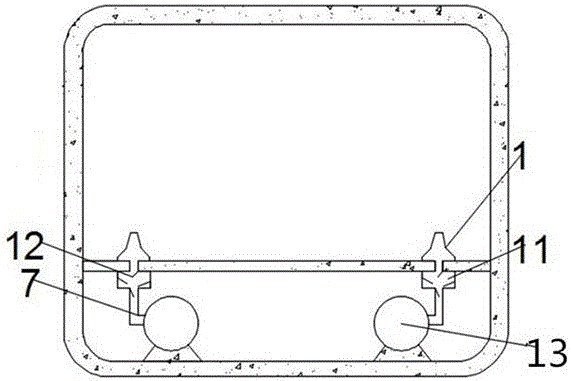

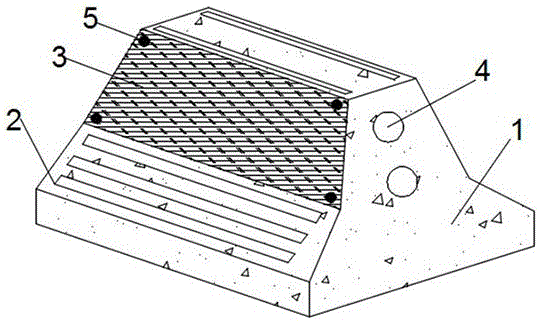

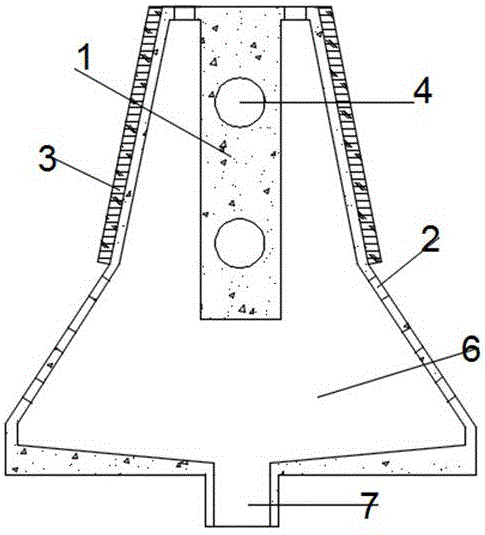

[0029] Such as Figure 1-Figure 8 As shown, the guardrail with flood prevention and drainage function for underground complexes includes concrete main body 1, drainage outlet 2, silicone sponge assembly 3, guardrail installation opening 4, bolts 5, drainage groove 6, drainage pipe 7, and spring net 8. Sponge pad 9, silica gel pad 10, buffer 11, energy-reducing plate 12, rainwater pipe 13, the main body of the guardrail with flood prevention and drainage function for the underground complex is composed of concrete main body 1, two sides of the lower side of concrete main body 1 Drain outlets 2 are provided on both sides of the side and the upper part, and silicone sponge assemblies 3 are provided on both sides of the upper side of the concrete main body 1; a guardrail installation port 4 is provided at the middle of the upper part of the concrete main body 1, and the guardrail installation port 4 runs through the entire concrete. Main body 1; fixed with bolts 5 between the sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com