Alkaline cell with improved reliability and discharge performance

A technology for alkaline batteries and battery cells, which is applied in the direction of alkaline batteries, alkaline battery electrodes, aqueous electrolyte batteries, etc., and can solve problems such as electrolyte leakage of battery cells, inhibition of discharge performance, impracticality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

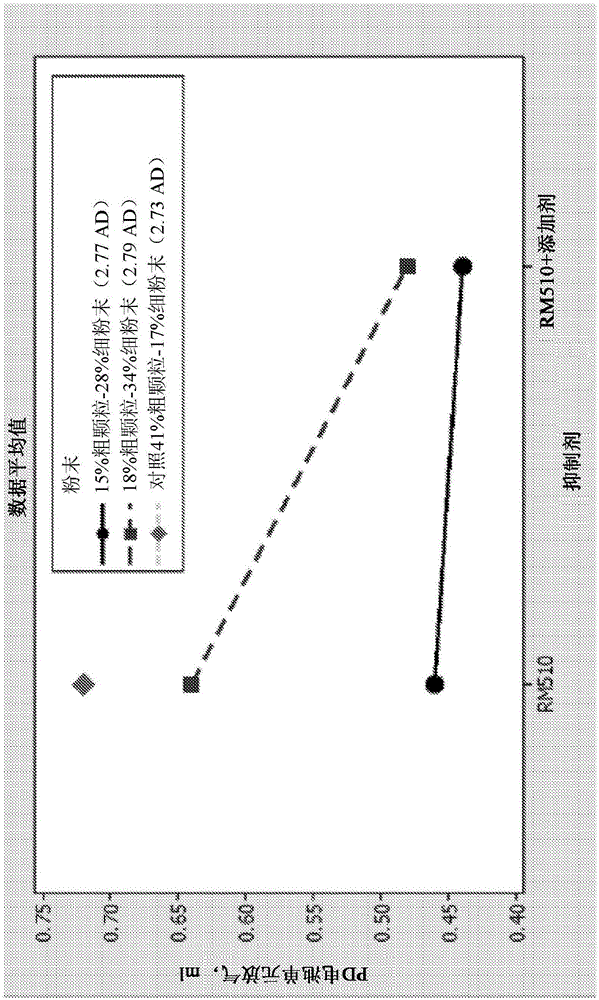

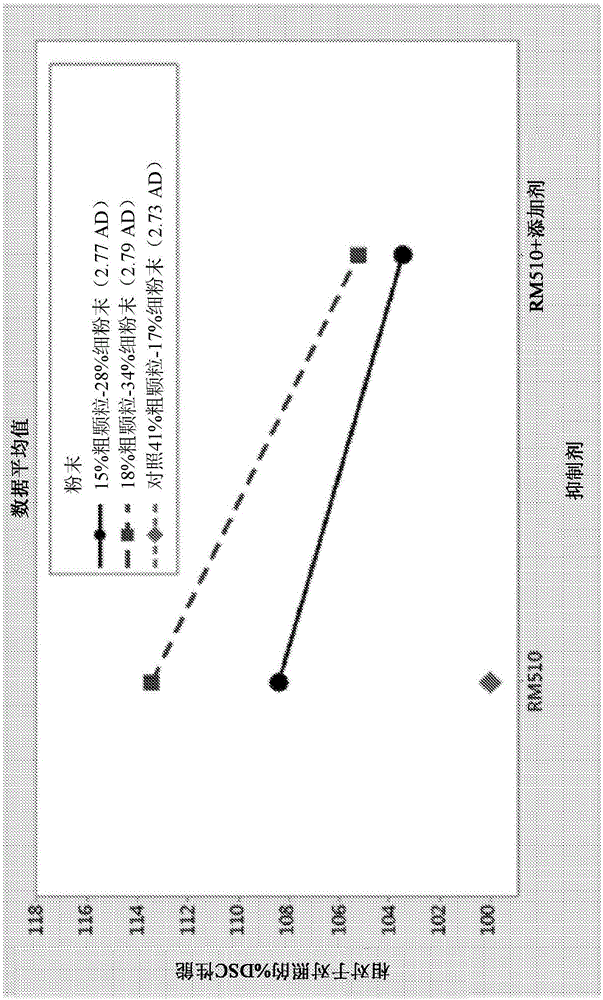

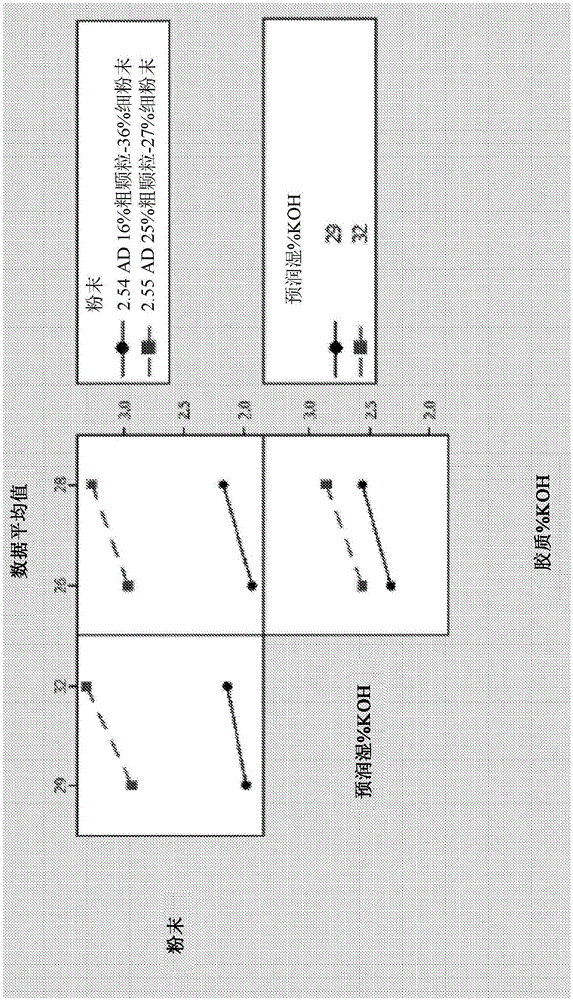

[0075] In the examples given below, electrochemical cells of the present disclosure were tested for DSC performance, drop test amperage (before and after drop), gassing of partially discharged cells, gassing of undischarged cells, and state after storage . Gel anodes were prepared according to modifications of the present disclosure.

[0076] Gel viscosity was measured using a Brookfield digital viscometer and Teflon coated spindle #06 at 4 rpm. When measuring, allow the reading to stabilize for more than 5 minutes before recording the viscosity value.

[0077] For yield stress value measurement, colloidal viscosity values were measured at 1.0rpm (R1) and 0.5rpm (R2), and the yield stress value was calculated using the following formula: yield stress value=(R2-R1) / 100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com