Three-phase jet-flow fire-fighting monitor system for gas-powder separation

An air-powder separation and fire monitor technology, applied in separation methods, dispersed particle separation, spray devices, etc., can solve the problems of reducing the fire monitor range, speeding up the atomization speed of jet water beams, and increasing the cost of nitrogen fire extinguishing, so as to reduce fire extinguishing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

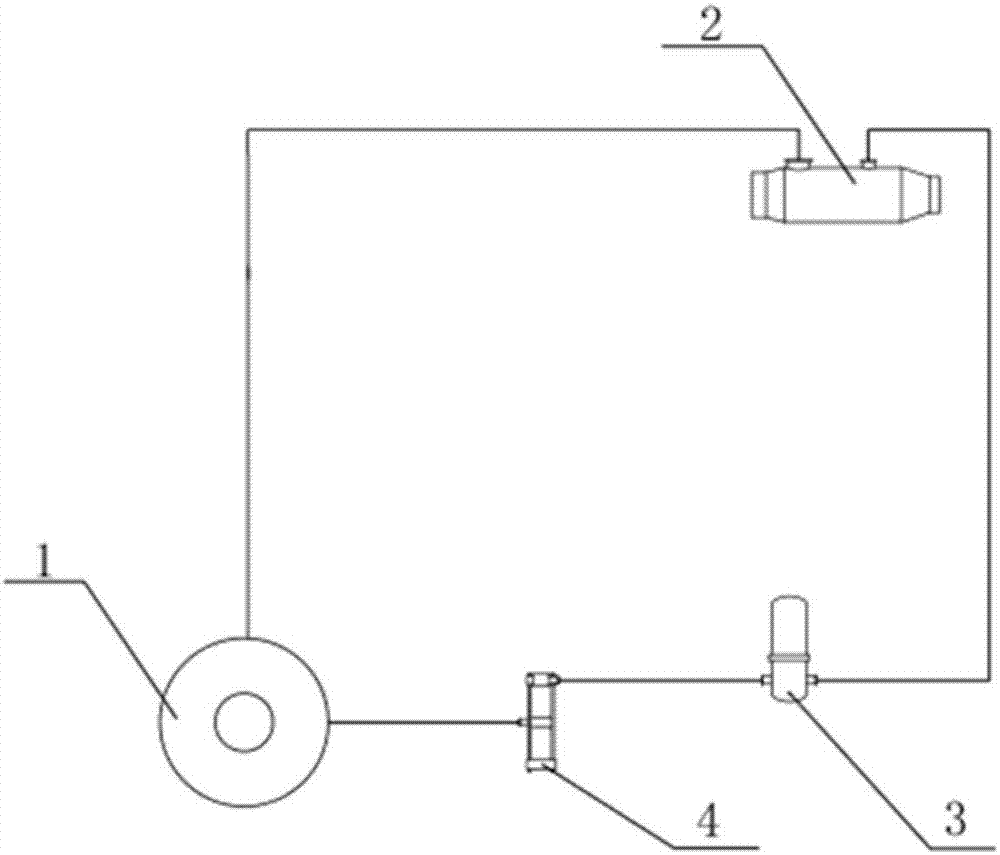

[0025] Embodiment 1: as Figure 1-5 As shown, the present embodiment provides a three-phase jet fire monitor system, which specifically includes: a dry powder tank 1, a gas-powder separation three-phase fire monitor head 2, a gas filter 3 and a nitrogen compression device 4, and the dry powder tank 1 passes through the pipeline Connected to the powder inlet pipe of the fire monitor head 2, the water tank and the water pump are connected to the water inlet pipe of the water monitor through the water delivery pipe, and the gas filter 3 and the nitrogen booster device 4 are installed on the nitrogen outlet pipe of the fire monitor head and the dry powder tank between.

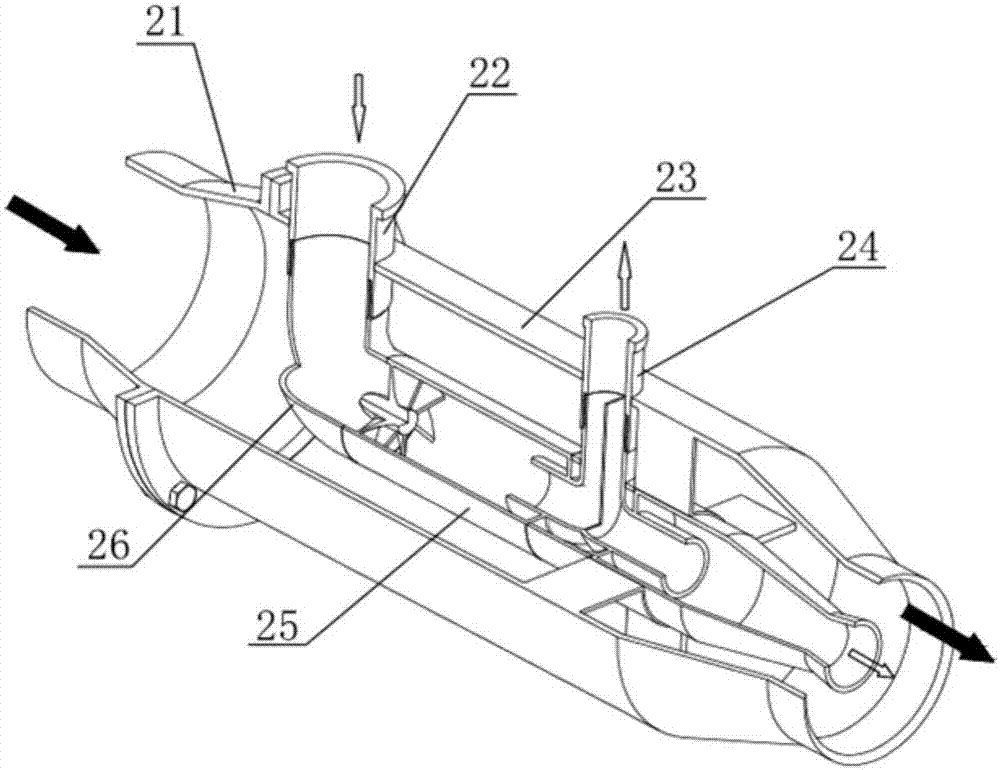

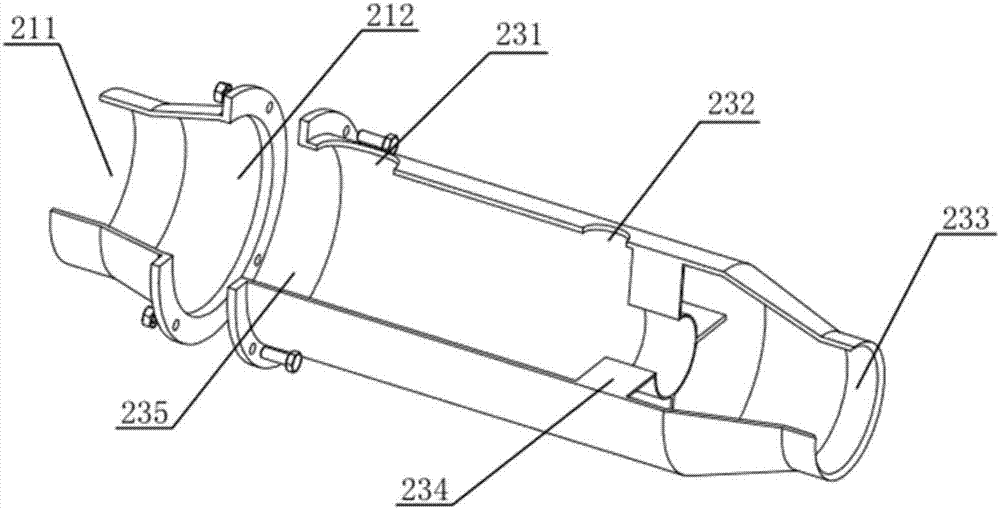

[0026] The three-phase fire monitor head includes a water monitor tube and a gas-powder separation dry powder tube. The water monitor tube is composed of a water monitor inlet pipe 21 and a water monitor tube main body 23. The water monitor inlet pipe 21 is round in shape. Platform-shaped structure, a water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com