AgBr/ZVO catalyst with visible light catalytic activity as well as preparation method and application thereof

A technology for catalysts and composite catalysts, applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited application, low utilization of sunlight, etc., to achieve high-efficiency photocatalytic degradation performance, improve The effect of visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

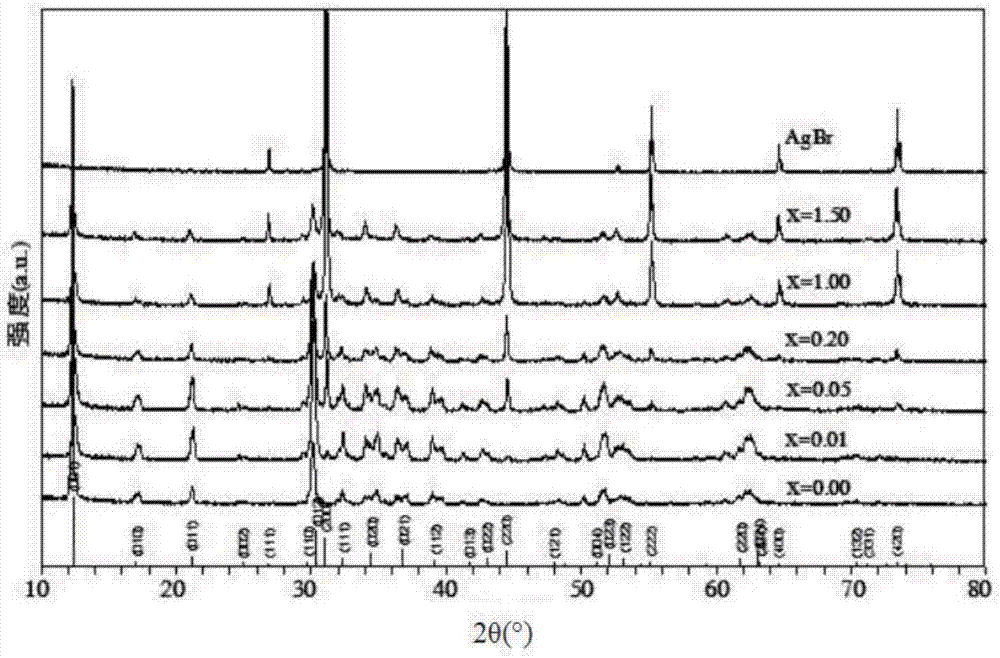

[0028] The preparation process of AgBr / ZVO composite catalyst is as follows:

[0029] Step 1, press Zn: V=3: 2 (mol ratio), take by weighing a certain amount of Zn (NO 3 ) 2 ·6H 2 O and NaVO 3 2H 2 O was dissolved in distilled water, NaVO 3 After the solution was ultrasonically dispersed, Zn(NO 3 ) 2 In the solution, continue magnetic stirring to obtain the precursor solution;

[0030] Step 2. Use concentrated ammonia water to adjust the pH of the precursor solution obtained in step 1 to 6-10 (the specific pH is 6, 8, and 10), stir evenly, transfer to the reaction kettle, and seal it well;

[0031] Step 3. Heat the precursor solution in the reactor in step 2 at 70-160°C (the specific temperatures are 70°C, 90°C, 120°C, 140°C, and 160°C) for 2-20h (the specific time is 2h, 10h, and 20h respectively) );

[0032] Step 4. After the reaction kettle in step 3 is naturally cooled to room temperature, filter, wash with distilled water several times, and dry to obtain zinc pyr...

Embodiment 2

[0042] In order to test the effect of the pH value of the precursor solution on the visible light activity of AgBr / ZVO, AgBr / ZVO composites were prepared under different pH values of the precursor solution when the hydrothermal temperature was 120 °C, the hydrothermal time was 10 h, and the composite ratio of AgBr was 0.05. catalyst. The results showed that when the pH value of the precursor solution was 10, the decolorization rate of AgBr / ZVO to methylene blue was the highest, and when the pH value of the precursor solution was acidic, the decolorization effect was poor. When the pH of the precursor solution was 6, the decolorization rate of AgBr / ZVO to methylene blue was 54.9%; when the pH of the precursor solution was 8, the decolorization rate of AgBr / ZVO to methylene blue was 65.5%; The decolorization rate of ZVO to methylene blue was 71.8%. Overall, the decolorization ability of AgBr / ZVO gradually increases with the increase of the pH value of the synthetic catalyst p...

Embodiment 3

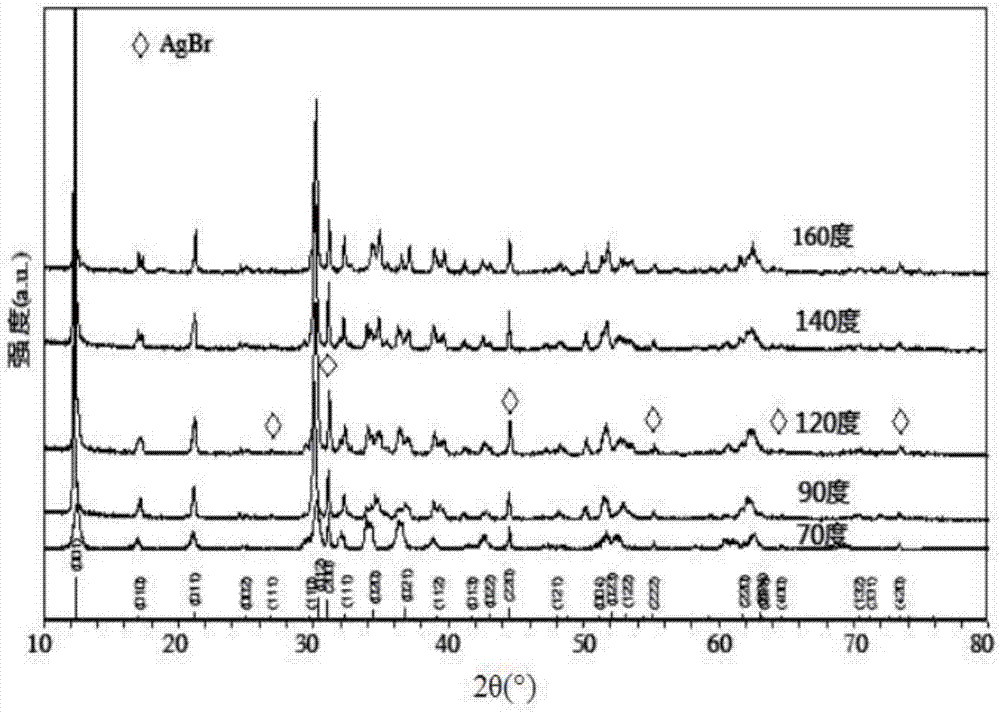

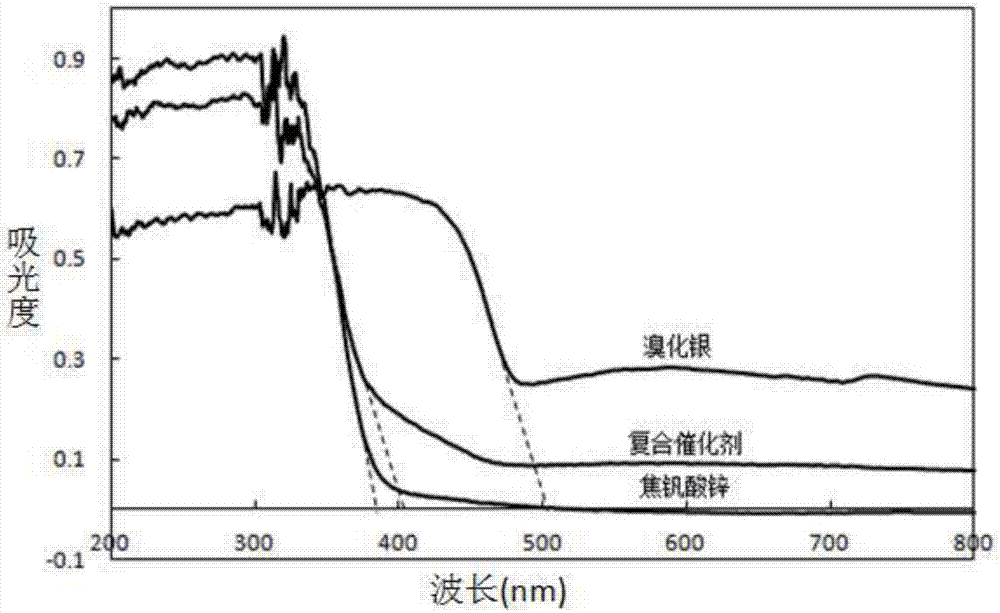

[0044] In order to examine the effect of hydrothermal temperature on the visible light activity of AgBr / ZVO, AgBr / ZVO composite catalysts were prepared at different hydrothermal temperatures when the precursor solution pH was 10, the hydrothermal time was 10 h, and the composite ratio of AgBr was 0.05. When the hydrothermal temperature was 70°C, 90°C, 120°C, 140°C, 160°C, the decolorization rate of AgBr / ZVO to methylene blue was 61.9%, 64.3%, 71.8%, 70.6%, 70.9%. The results showed that the decolorization rate of methylene blue was the highest when the hydrothermal temperature was 120°C. Combined with the XRD patterns of the composite catalysts prepared at different hydrothermal temperatures, it can be seen that the crystal form of the catalyst gradually becomes better with the increase of the hydrothermal temperature, which can improve the photocatalytic activity of the catalyst to a certain extent; but with the increase of the crystallinity , the particle size of the catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com