Preparation method and application of near-infrared light response type thin-layer carbon nitride photocatalytic material

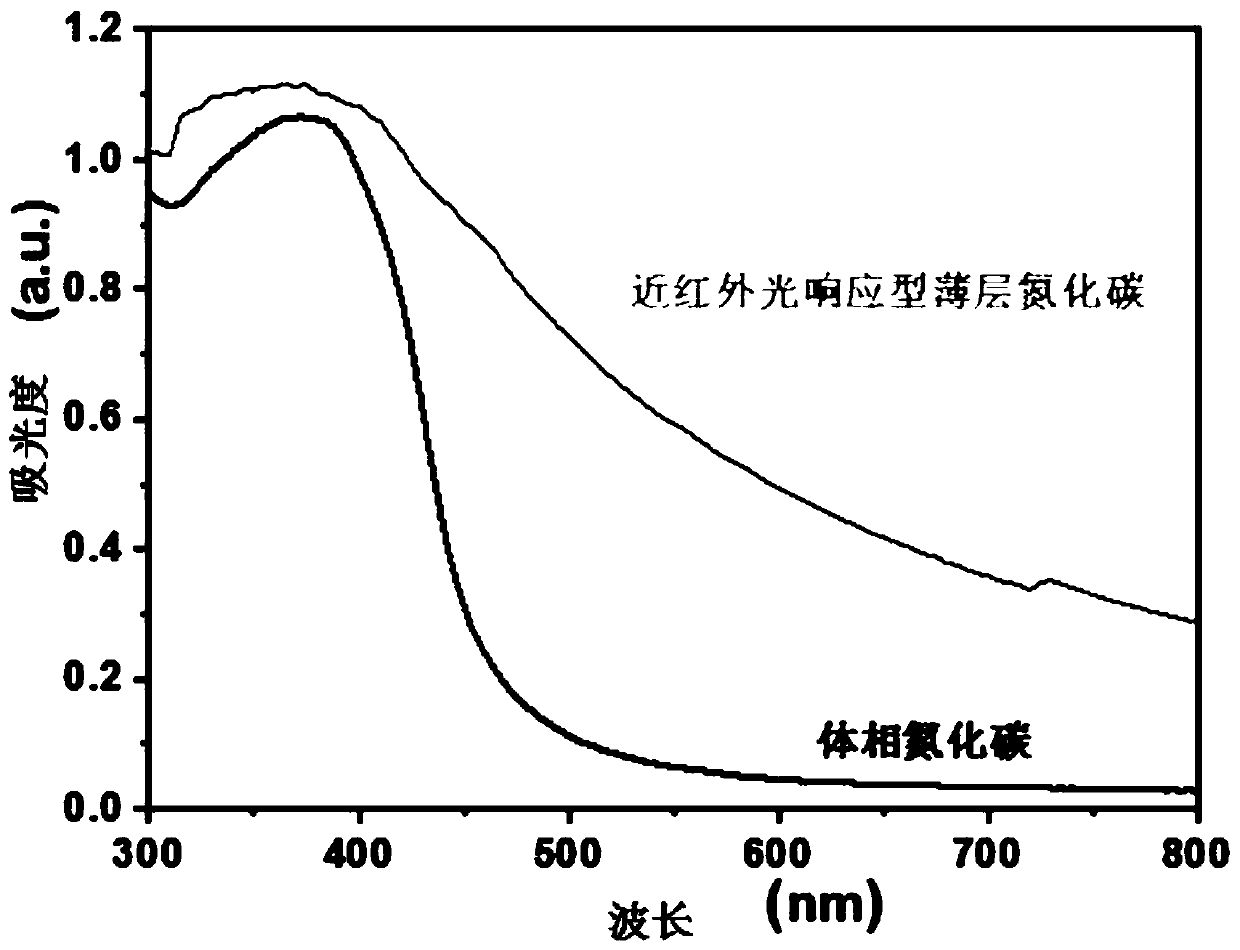

A technology of near-infrared photoresponsive and catalytic materials, which is applied in the field of preparation of near-infrared photoresponsive thin-layer carbon nitride photocatalytic materials, which can solve the problems of low utilization rate of sunlight and achieve high-efficiency photocatalytic degradation performance and simple raw materials , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

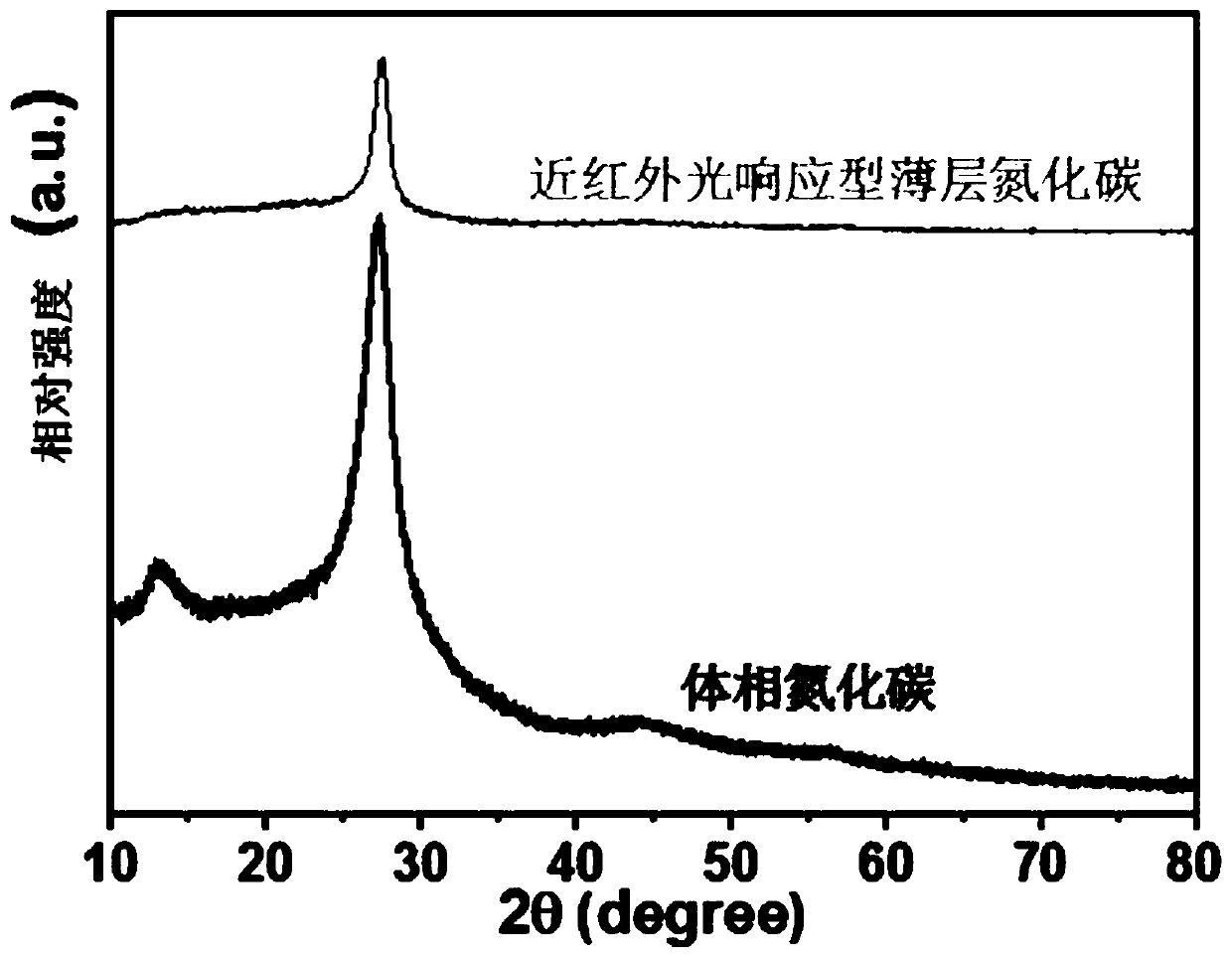

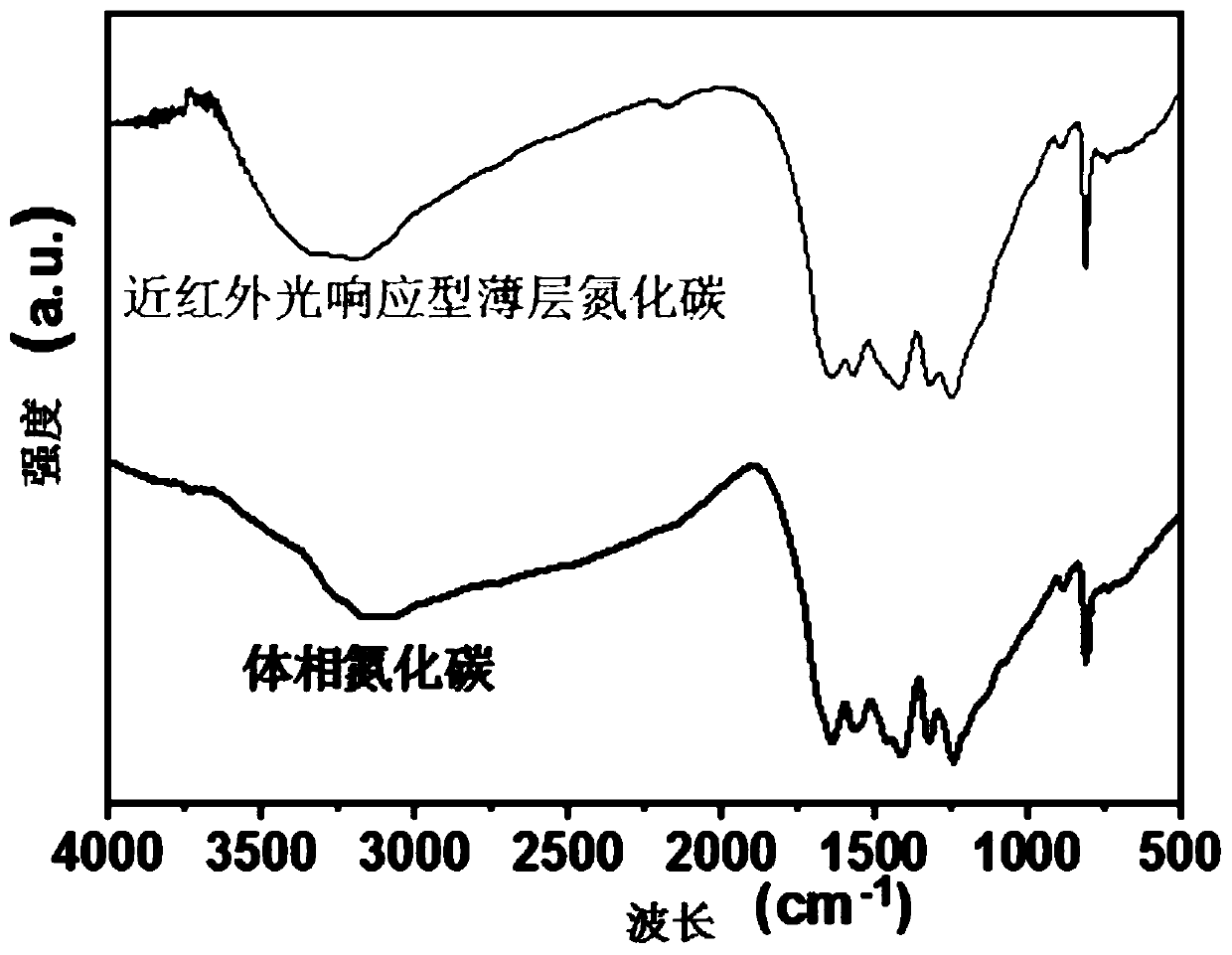

[0026] A method for preparing a near-infrared photoresponsive thin-layer carbon nitride photocatalytic material, comprising the following steps:

[0027] The first step (the first calcination): Weigh nine portions of 2.5 g melamine and place them in nine crucibles (the crucibles need to be covered), and place the nine crucibles (arranged in 3×3) in the central temperature of the muffle furnace. Calcination was carried out in a controlled area; the heating parameters were as follows: set the temperature from room temperature to 600 °C at a uniform speed after 220 min, and at 600 °C ◦ C for 4 hours; then cooled naturally, the obtained solid is near-infrared photoresponsive multilayer carbon nitride (non-commercial, prepared by the above steps), and the next stage of operation was carried out after grinding.

[0028] The second step (the second calcination): Weigh six parts of 0.4 g ground near-infrared light-responsive multilayer carbon nitride and place them in six arks, and pl...

Embodiment 2

[0030] A method for preparing a near-infrared photoresponsive thin-layer carbon nitride photocatalytic material, comprising the following steps:

[0031] The first step (the first calcination): Weigh nine portions of 2.8 g melamine and place them in nine crucibles (the crucibles need to be covered), and place the nine crucibles (arranged in 3×3) in the central temperature of the muffle furnace. Calcination was carried out in a controlled area; the heating parameters were as follows: set the temperature from room temperature to 620 °C at a constant speed for 250 min, and keep it at 620 °C for 3 hours; Non-commercial, prepared by the above steps), after grinding, proceed to the next stage of operation.

[0032] The second step (the second calcination): Weigh six parts of 0.5 g ground near-infrared light-responsive multilayer carbon nitride and place them in six arks, and place the six arks (in a 3×2 arrangement) Calcination was carried out in the central temperature control zon...

Embodiment 3

[0034] A method for preparing a near-infrared photoresponsive thin-layer carbon nitride photocatalytic material, comprising the following steps:

[0035] The first step (the first calcination): Weigh nine parts of 3 g melamine and place them in nine crucibles (the crucibles need to be covered), and put the nine crucibles (arranged in 3×3) in the central temperature of the muffle furnace. Calcination was carried out in a controlled area; the heating parameters were as follows: set the temperature from room temperature to 650 °C at a uniform rate after 300 min, and set the temperature at 650 °C ◦ C for 2 hours; then cooled naturally, the obtained solid is near-infrared photoresponsive multilayer carbon nitride (non-commercial, prepared by the above steps), and the next stage of operation was carried out after grinding.

[0036] The second step (the second calcination): Weigh six parts of 0.6 g of ground near-infrared light-responsive multilayer carbon nitride and place them in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com