Seawater composite liquid fertilizer, preparation method and application thereof

A technology of compound liquid and sea water, applied in application, nitrogen fertilizer, ammonium salt fertilizer and other directions, can solve the problems of lack of medium and trace mineral elements, solid fertilizer is not easy to dissolve, and fertilizer crystallization temperature is high, so as to improve the lack of mineral elements and reduce the price. , the effect of low acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of boron-containing seawater compound liquid fertilizer:

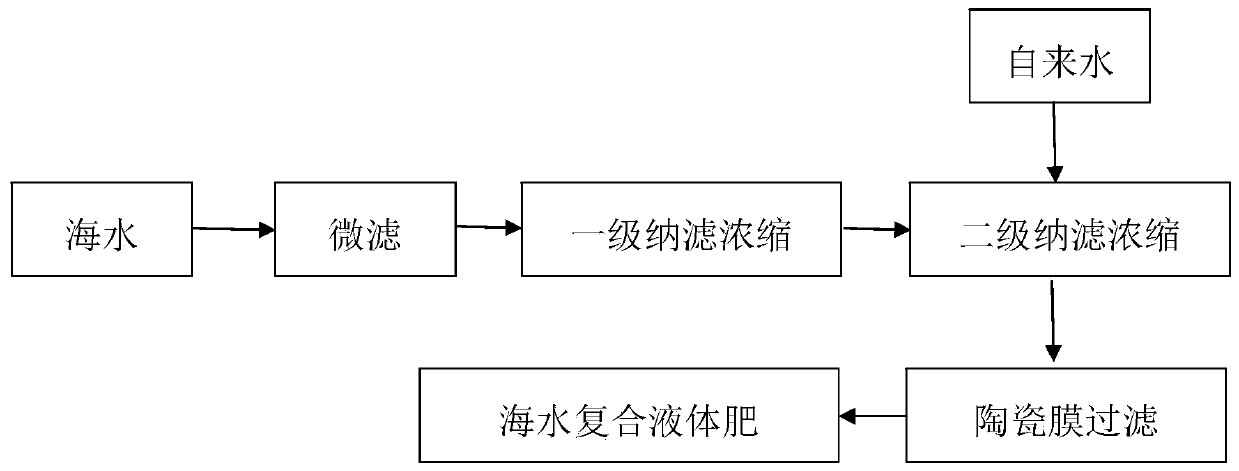

[0029] (1) Using the second-class seawater in the Bohai Bay sea area as raw material, the organic organisms and impurities in the seawater are filtered through a microfiltration membrane with a pore size of 0.5 μm. The operating pressure of the microfiltration membrane is 0.01MPa;

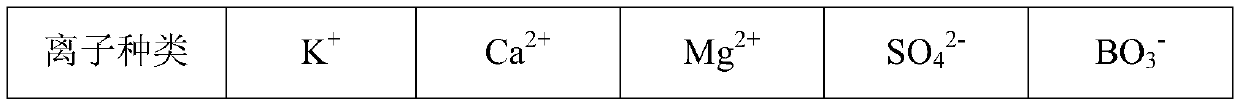

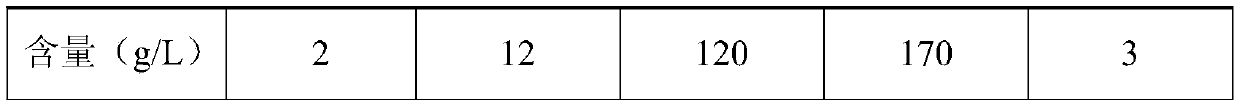

[0030] (2) The seawater discharged from the microfiltration system enters the first-level nanofiltration system, and is circulated and concentrated through the first-level nanofiltration system. The pore size of the nanofiltration membrane is 1nm, and the operating pressure is 2MPa to remove most of the monovalent ions (Na + , Cl - 、K + 、Br - , I - ), the remaining concentrated solution is mixed with tap water;

[0031] (3) The concentrated solution is mixed with tap water and then concentrated by a secondary nanofiltration system until the total amount of dissolved solids in the concentrated solution reaches...

Embodiment 2

[0037] A preparation method of iron-containing seawater compound liquid fertilizer:

[0038] (1) Using the second-class seawater in the Bohai Bay sea area as raw material, the organic organisms and impurities in the seawater are filtered through a microfiltration membrane with a pore size of 0.5 μm. The operating pressure of the microfiltration membrane is 0.1MPa;

[0039] (2) The seawater discharged from the microfiltration system enters the first-level nanofiltration system, and is circulated and concentrated through the first-level nanofiltration system. The pore size of the nanofiltration membrane is 1nm, and the operating pressure is 3MPa to remove most of the monovalent ions (Na+, Cl- , K+, Br-, I-), the remaining concentrated solution is mixed with tap water;

[0040] (3) The concentrated solution is mixed with tap water and then concentrated by a secondary nanofiltration system until the total amount of dissolved solids in the concentrated solution reaches 240g / L, whic...

Embodiment 3

[0045] A preparation method of manganese-copper seawater composite liquid fertilizer:

[0046] (1) Using the second-class seawater in the Bohai Bay sea area as raw material, the organic organisms and impurities in the seawater are filtered through a microfiltration membrane with a pore size of 0.5 μm. The operating pressure of the microfiltration membrane is 0.1MPa;

[0047] (2) The seawater discharged from the microfiltration system enters the first-level nanofiltration system, and is circulated and concentrated through the first-level nanofiltration system. The pore size of the nanofiltration membrane is 1nm, and the operating pressure is 4MPa to remove most of the monovalent ions (Na+, Cl- , K+, Br-, I-), the remaining concentrated solution is mixed with tap water;

[0048](3) The concentrated solution is mixed with tap water and then concentrated by a secondary nanofiltration system until the total amount of dissolved solids in the concentrated solution reaches 200g / L, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com