Novel lubricating grease for railway switch machine and preparation method

A switch machine and grease technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as corrosion, high-temperature flow, poor startup, etc., and achieve excellent low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

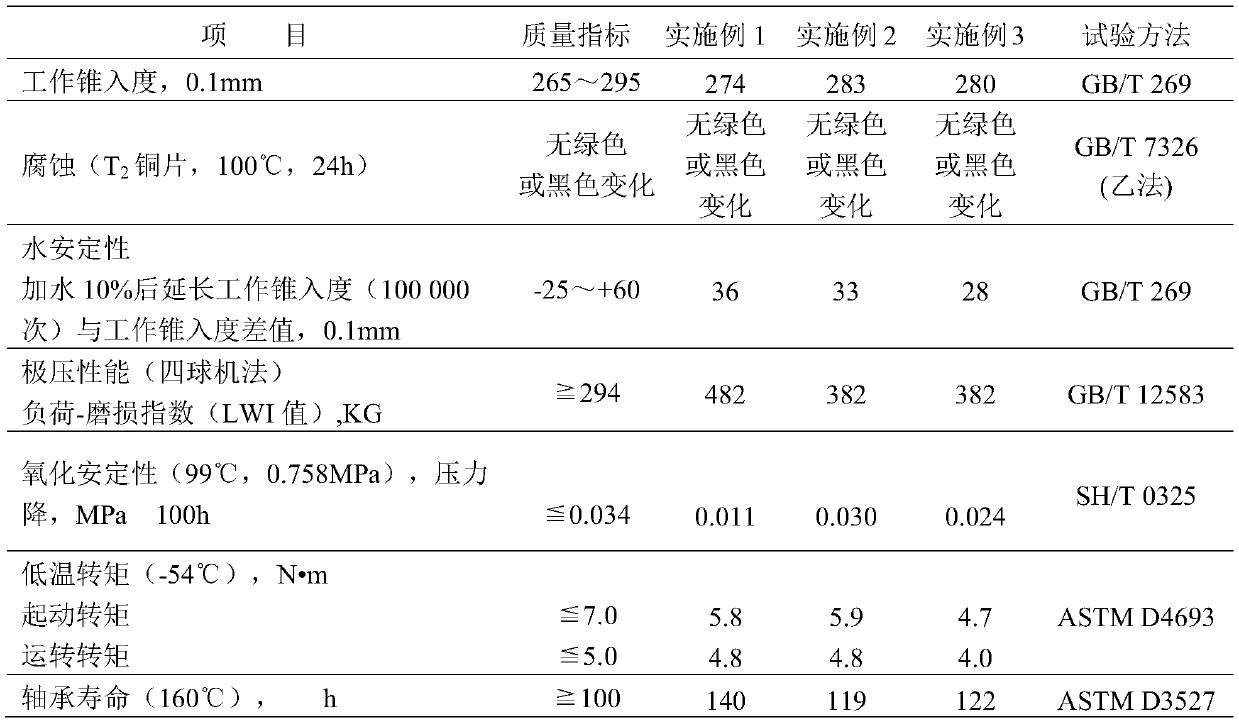

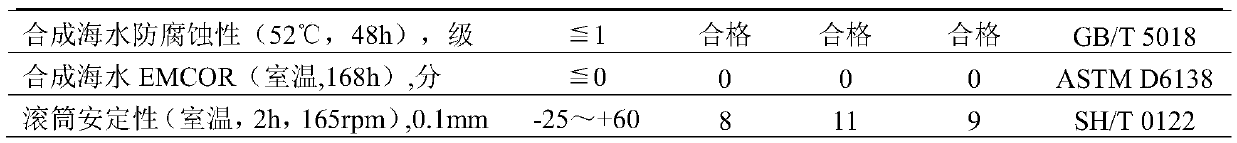

Examples

Embodiment 1

[0026] A new type of lubricating grease for railway switch switch machines, comprising the following components in parts by mass: 55 parts of refined minus three-line mineral oil, 11 parts of 150 BS base oil, 12 parts of lauryl hydroxystearic acid, 2.5 parts of sebacic acid, 2 parts of lithium hydroxide monohydrate, 0.5 parts of calcium hydroxide, 0.7 parts of diphenylamine, 7 parts of ethylene-propylene rubber, 2 parts of T202 anti-oxidation, anti-corrosion and anti-wear agent, 6 parts of lead naphthenate, 4 parts of vulcanized cottonseed oil, 0.05 part of octadecyl alcohol, 0.1 part of 2,6-di-tert-butylphenol.

[0027] A method for preparing novel railway turnout switch machine lubricating grease, comprising the steps of:

[0028] The first step: Feeding

[0029] In the production kettle A, add 3 / 5 of the refined minus third-line mineral oil;

[0030] Step 2: React

[0031] Add lauryl hydroxystearic acid, stir until melting, then put sebacic acid into production kettle A ...

Embodiment 2

[0040] A new type of lubricating grease for railway turnout switch machines, comprising the following components in parts by mass: 58 parts of refined minus three-line mineral oil, 12 parts of 150 BS base oil, 11 parts of lauryl hydroxystearic acid, 2.5 parts of sebacic acid, 2 parts of lithium hydroxide monohydrate, 0.5 parts of calcium hydroxide, 0.7 parts of diphenylamine, 7 parts of ethylene-propylene rubber, 2 parts of T202 anti-oxidation, anti-corrosion and anti-wear agent, 6 parts of lead naphthenate, 4 parts of vulcanized cottonseed oil, 0.05 part of octadecyl alcohol, 0.1 part of 2,6-di-tert-butylphenol.

[0041] A method for preparing novel railway turnout switch machine lubricating grease, comprising the steps of:

[0042] The first step: Feeding

[0043] In the production kettle A, add 3 / 5 of the refined minus third-line mineral oil;

[0044] Step 2: React

[0045] Add lauryl hydroxystearic acid, stir until melting, then put sebacic acid into production kettle A...

Embodiment 3

[0054]A new type of lubricating grease for railway turnout switch machines, comprising the following components in parts by mass: 57 parts of refined minus three-line mineral oil, 12 parts of 150 BS base oil, 12 parts of lauryl hydroxystearic acid, 2.5 parts of sebacic acid, 2 parts of lithium hydroxide monohydrate, 0.5 parts of calcium hydroxide, 0.7 parts of diphenylamine, 7 parts of ethylene-propylene rubber, 2 parts of T202 anti-oxidation, anti-corrosion and anti-wear agent, 8 parts of lead naphthenate, 5 parts of vulcanized cottonseed oil, 0.05 part of octadecyl alcohol, 0.1 part of 2,6-di-tert-butylphenol.

[0055] A method for preparing novel railway turnout switch machine lubricating grease, comprising the steps of:

[0056] The first step: Feeding

[0057] In the production kettle A, add 3 / 5 of the refined minus third-line mineral oil;

[0058] Step 2: React

[0059] Add lauryl hydroxystearic acid, stir until melting, then put sebacic acid into production kettle A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com