Modified HAP composite material for removing fluoride in water body as well as preparation method and application of the modified HAP composite material

A composite material and modification technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of high economic benefits, lack of reliable reliability, etc., and achieve easy availability of raw materials, low cost, and preparation methods. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

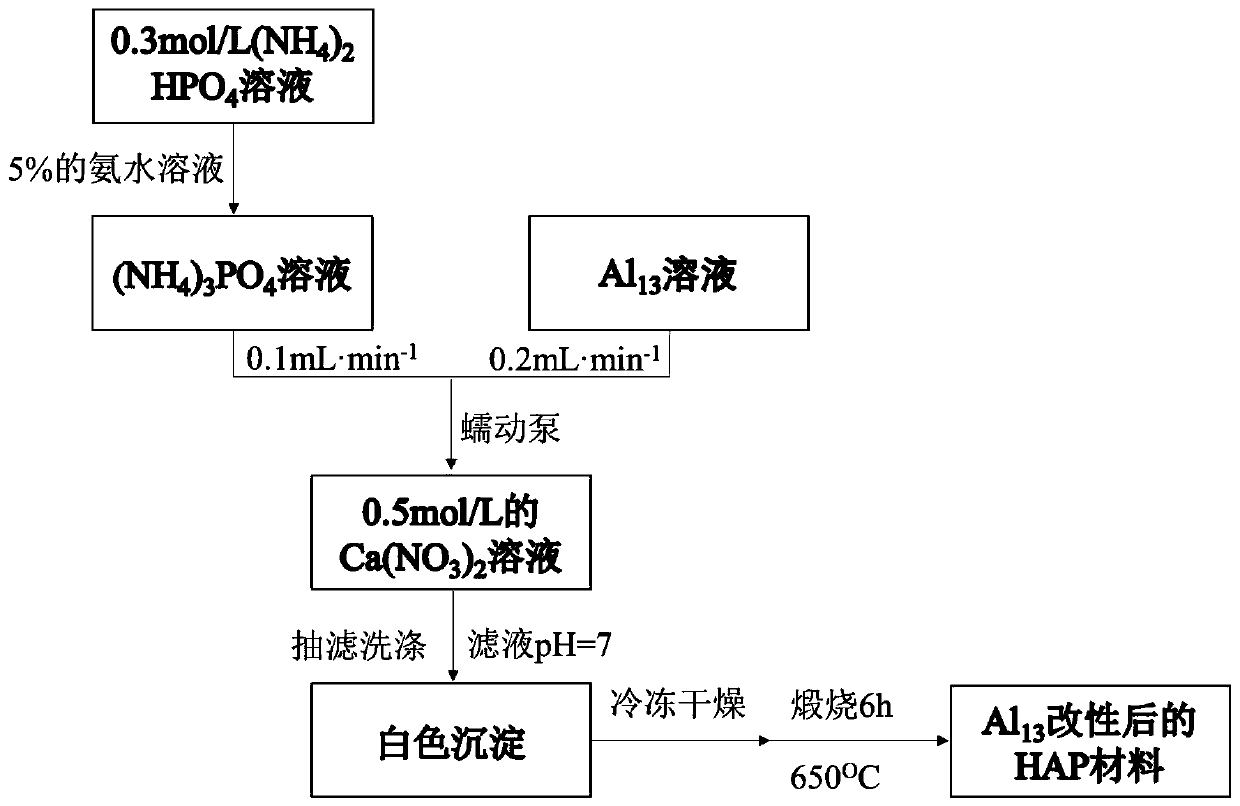

[0022] The invention discloses a preparation method of a modified HAP composite material, comprising:

[0023] (1) The configured Al 13 solution and (NH 4 ) 3 PO 4 solution or Na 3 PO 4 The solution was added with Ca(NO 3 ) 2 solution or CaCl 2 Aging after reaction in the solution to obtain a mixed solution;

[0024] (2) Filtrating the mixed solution to obtain a precipitate, drying the precipitate and then sintering to obtain the modified HAP composite material.

[0025] In some embodiments of the present invention, the molar ratio of Al and Ca in the mixed solution in step (1) is (3.6 to 3.8):9, specifically 3.62:9, 3.63:9, 3.64:9, 3.65:9, 3.66:9, 3.68:9, 3.7:9, 3.71:9, 3.72:9, 3.73:9, 3.75:9, 3.78:9, 3.8:9; the molar ratio of Ca and P is (2.9 to 3.1): 2, specifically 2.9: 2, 2.95: 2, 3.0: 2, 3.05: 2, 3.1: 2.

[0026] In some embodiments of the present invention, Al described in step (1) 13 The concentration of the solution is 0.08 to 0.12mol / L, specifically 0.08m...

Embodiment 1

[0048] The preparation method of the modified HAP composite material with efficient removal of fluoride in the water body of this implementation, such as figure 1 As shown, through HAP and Al with high-efficiency defluorination performance 13 The combination of fluoride can improve the removal efficiency and adsorption capacity of fluoride, and provide technical support for ensuring good effluent water quality. Specifically include the following steps:

[0049] 1) Prepare AlCl with a concentration of 0.2mol / L 3 solution, 0.25mol / L Na 2 CO 3 Solution, using slow alkali drop method, to 0.2mol / L AlCl 3 Slowly add 0.25mol / L Na to the solution 2 CO 3 solution, the dropping rate is controlled at 0.1-0.15mL·min -1 , and then undergo a purification step to produce [OH + ] and [Al 3+ ] The molar ratio is 2.2:1, Al b >90% Al 13 solution, Al concentration of 0.1mol / L Al 13 solution. Among them, the Al 13 Solution B=2.2, Al b >90%.

[0050] 2) Prepare 0.5mol / L Ca(NO 3 ) ...

Embodiment 2

[0057] The difference between embodiment 2 and embodiment 1 only lies in the Ca(NO 3 ) 2 The solution was changed to CaCl 2 solution, other things remain unchanged, and Al can also be obtained 13 Modified HAP material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com