Titanate nanotube composite type photocatalyst as well as preparation method and application thereof

A nanotube composite and photocatalyst technology, which is applied in the field of titanate nanotube composite photocatalyst and its preparation, to achieve the effects of easy recycling, high photocatalytic activity and selectivity, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

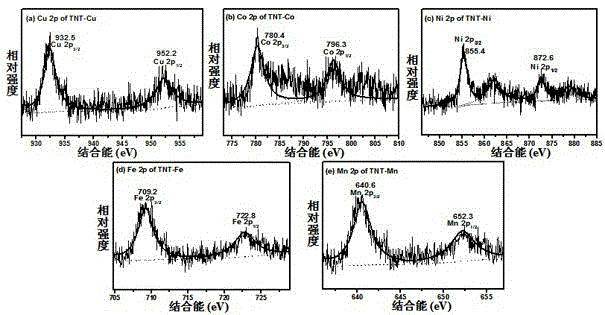

[0039] Anatase TiO 2 (10 nm, 0.5 g) dispersed in 40 mL of 10 M NaOH solution, mixed and stirred uniformly, then placed in a reaction kettle at 140 ℃ for 12 h water heating, then cooled, filtered, and washed with water to pH 8, then use Washed with ethanol, and finally dried at 80 ℃ to obtain a solid, and then calcined at 400 ℃ for 6 h to obtain TNT with a one-dimensional tubular structure. The metal ion precursor salt M(CH 3 COO) 2 (M=Cu, Co, Ni, Fe or Mn) dissolved in water to form 50 mL 3 mM solution, then add ammonia (25%) dropwise to the solution, then add the above TNT to the solution and continue stirring for 20 h , Then filter, wash with ammonia, wash the solution to pH 8, and finally dry to obtain a one-dimensional tubular structure of TNT-M (Cu, Co, Ni, Fe or Mn) photocatalyst. Mix 8 mg of catalyst, 1.5 mL BTF that has been pre-passed with oxygen, and 0.1 mmol alcohol, and place it under visible light (> The photocatalytic activity and selectivity of a series of cataly...

Embodiment 2

[0044] Anatase TiO 2 (10 nm, 0.5 g) dispersed in 40 mL 10 M NaOH solution, mixed and stirred evenly, then 0.3856 g Cd(NO 3 ) 2 ·4H 2 O and 0.1033 g TAA, continue to stir for 0.5 h, and then place in the reaction kettle at 140 ℃ for 48 h, then cool, filter, wash the solution with water to pH 7, and finally dry at 60 ℃ to obtain a one-dimensional tubular structure of CdS / TNT Composite photocatalyst. Mix 8 mg of catalyst, 1.5 mL BTF with oxygen pre-passed with 0.1 mmol alcohol, and place it under visible light (> The photocatalytic activity and selectivity of a series of catalysts as shown in Table 2 were obtained by illuminating for 2 h under 420 nm).

[0045] Table 2 shows the selective alcohol activity of TNT, CdS / TNT and CdS catalysts

[0046]

[0047]

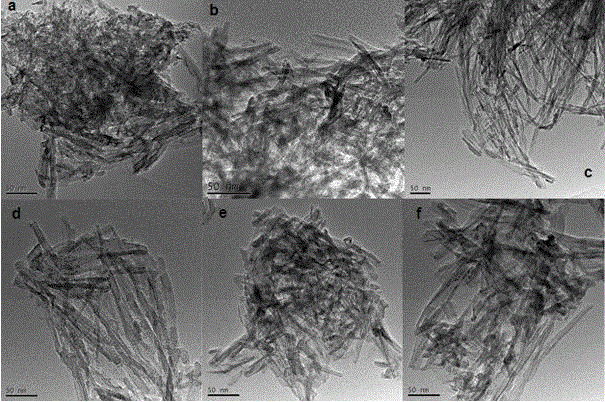

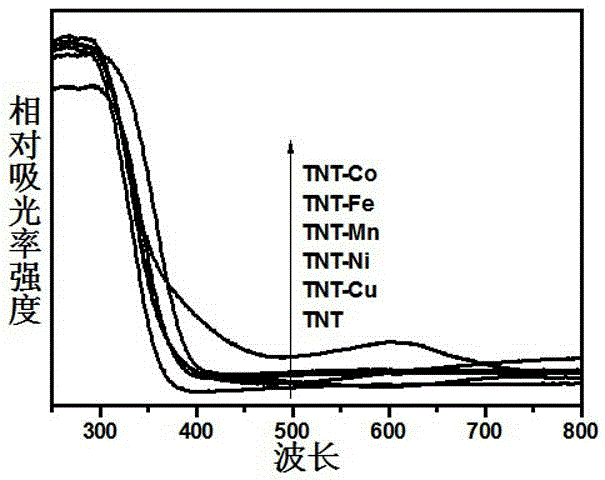

[0048] figure 1 These are the TEM images of TNT (a), TNT-Cu (b), TNT-Co (c), TNT-Ni (d), TNT-Fe (e) and TNT-Mn (f). From figure 1 We can see that the metal ion doped TNT does not affect or change the one-dimensional tubular struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com