Tin sulfide-graphene oxide composite photocatalyst as well as preparation method and application thereof

A graphene composite and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water treatment of special compounds, etc., can solve the problems of increasing process and complexity, and improve visible light catalytic activity and synthesis conditions Gentle, high photocatalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

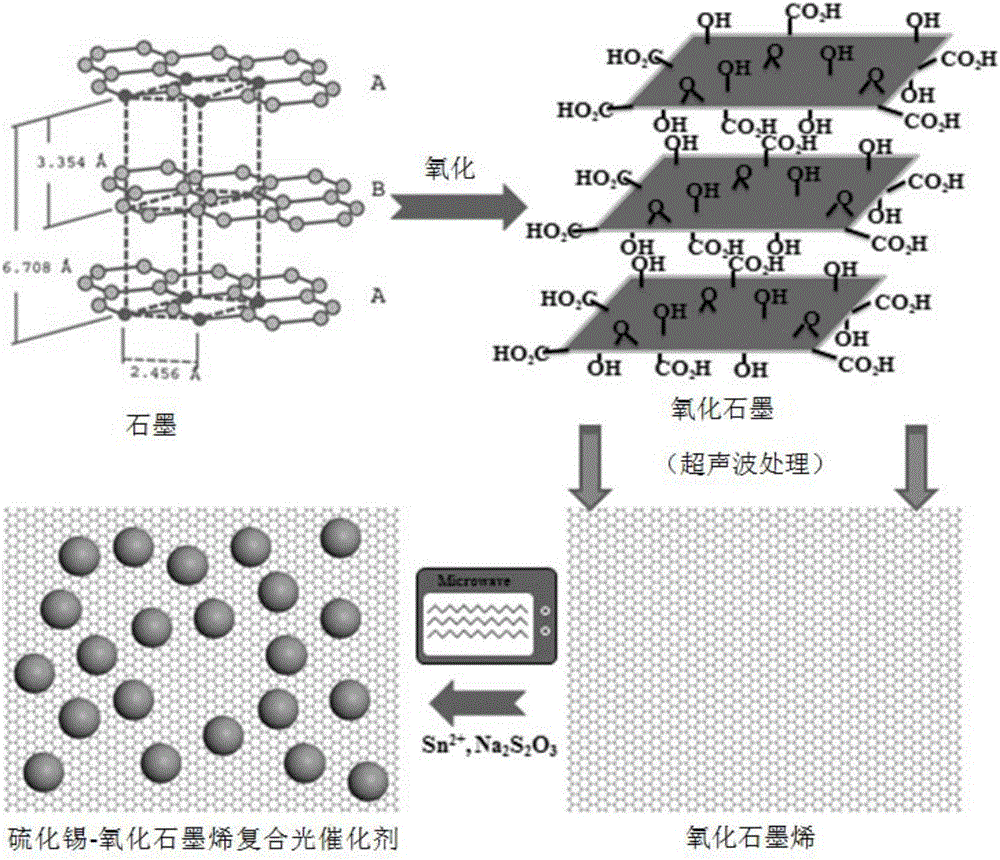

[0037] The preparation method of tin sulfide-graphene oxide composite photocatalyst comprises step S1: mixing stannous chloride dihydrate, water and ethylene glycol to obtain a first mixed solution.

[0038] Wherein, the dosage ratio of stannous chloride dihydrate, water and ethylene glycol is 0.27-0.31g: 8-12ml: 185-195ml.

[0039] The water is selected from one or more of deionized water, distilled water and ultrapure water, preferably deionized water.

[0040] The preparation method of the tin sulfide-graphene oxide composite photocatalyst further includes step S2: mixing the first mixed solution with the graphene oxide solution to obtain a second mixed solution.

[0041] Wherein, the concentration of the graphene oxide solution is 8-12 mg / ml, preferably 10 mg / ml. The graphene oxide solution with this concentration is beneficial to the deposition of tin sulfide nanoparticles.

[0042] The volume ratio of the first mixed solution to the graphene oxide solution is 193-207:1...

Embodiment 1

[0056] The preparation method of the tin sulfide-graphene oxide composite photocatalyst provided by the present embodiment comprises the following steps:

[0057] Step S1: Mix stannous chloride dihydrate, distilled water and ethylene glycol according to the dosage ratio of 0.27g: 12ml: 185ml to obtain the first mixed solution;

[0058] Step S2: disperse the graphene oxide in deionized water and ultrasonically for 4 hours (amplitude set to 45%) to obtain a graphene oxide solution with a concentration of 8 mg / ml, and mix the first mixed solution with the graphene oxide solution according to the ratio of 197:17 The volume ratio is mixed to obtain the second mixed solution;

[0059] Step S3: Mix the second mixed solution with polyvinylpyrrolidone and sodium thiosulfate according to the dosage ratio of 214ml: 0.002g: 0.2g to obtain the third mixed solution;

[0060] Step S4: Use ammonia water to adjust the pH of the third mixed liquid to 7.5, then place the third mixed liquid in a...

Embodiment 2

[0065] The preparation method of the tin sulfide-graphene oxide composite photocatalyst provided by the present embodiment comprises the following steps:

[0066] Step S1: Mix stannous chloride dihydrate, ultrapure water and ethylene glycol according to the dosage ratio of 0.31g:8ml:195ml to obtain the first mixed solution;

[0067] Step S2: disperse the graphene oxide in deionized water and ultrasonically for 5 hours (amplitude set to 50%) to obtain a graphene oxide solution with a concentration of 12 mg / ml, and mix the first mixed solution and the graphene oxide solution according to the ratio of 203:23 Mix by volume ratio to obtain the second mixed solution, and ultrasonically treat the second mixed solution for 32 minutes;

[0068] Step S3: Mix the second mixed solution with polyvinylpyrrolidone and sodium thiosulfate according to the dosage ratio of 226ml: 0.002g: 0.205g to obtain the third mixed solution. Place the third mixed solution at room temperature and stir it mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com