Automatic large-size workpiece machining device

A processing device, large-scale technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of unfavorable automation, no automatic loading and unloading mechanism, and increase the labor burden of operators, so as to realize automation, improve processing efficiency and process The effect of quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

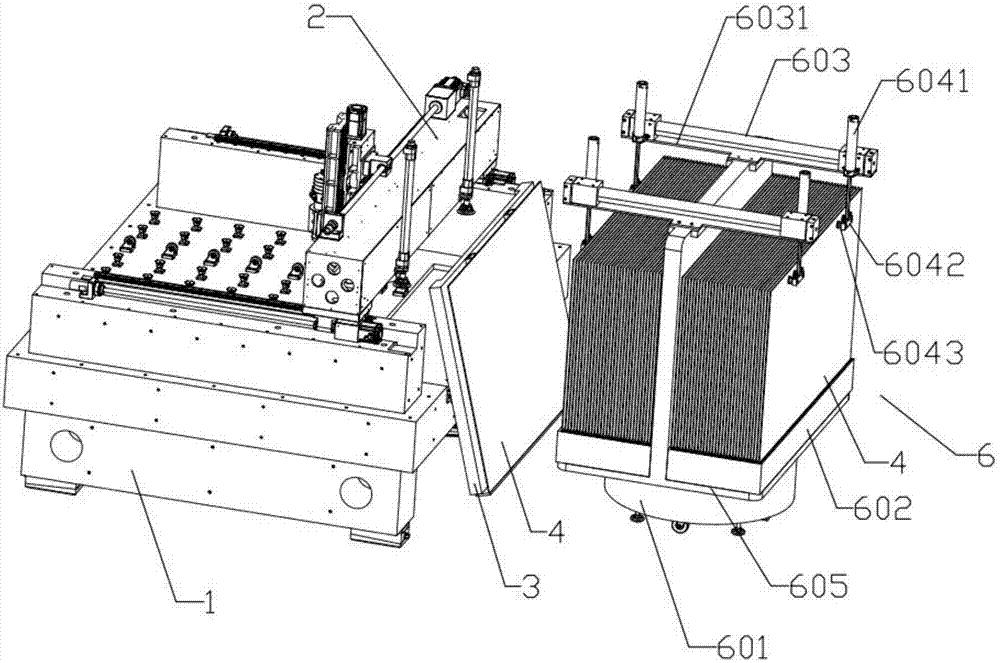

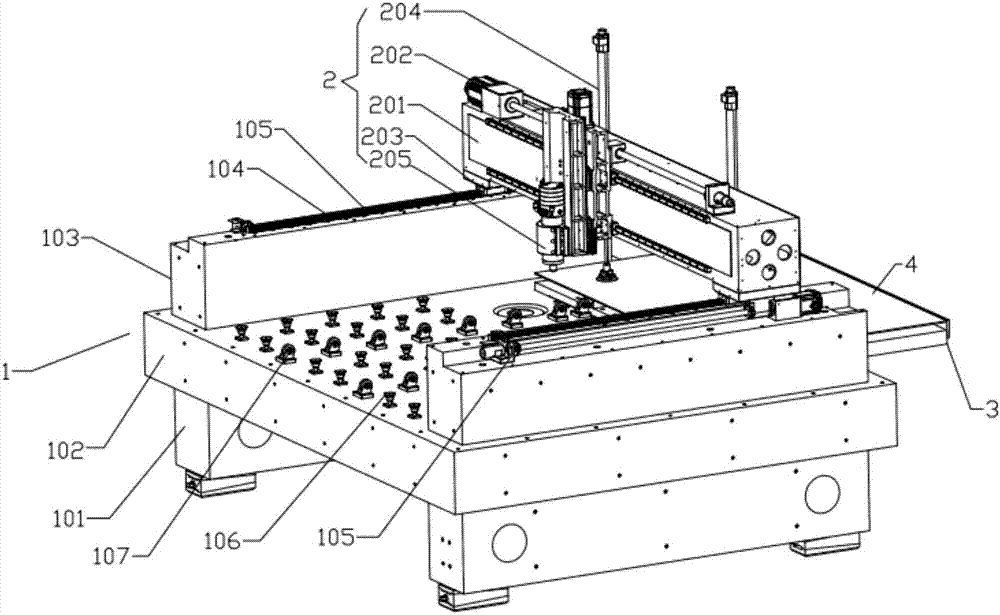

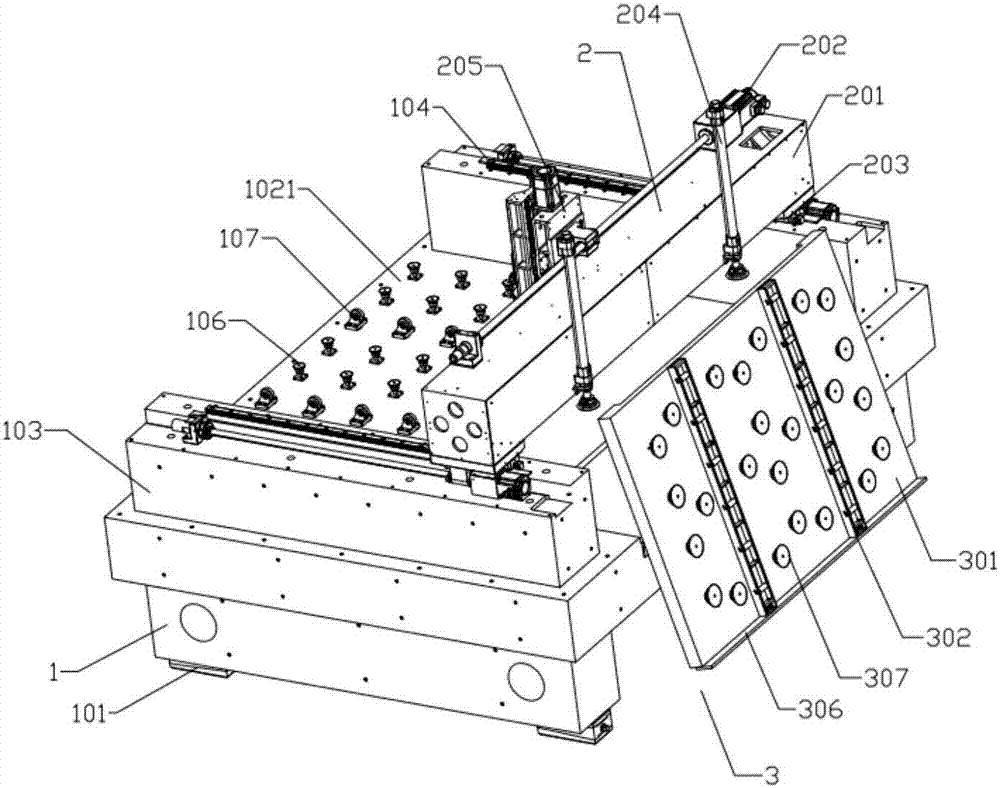

[0032] Attached below figure 1 - attached Figure 17 The present invention is described in further detail.

[0033] refer to Figure 1 to Figure 4, the present invention provides a large-size workpiece automatic processing device, including a working platform 1, the working platform 1 includes a base 101, a bed 102 on the base 101, columns 103 on the left and right sides of the bed 102, and a set On the first guide rail 104 on the column 103 , the front side of the bed 102 is a processing table 1021 , and the back side of the bed 102 is provided with a limiting groove 108 . The loading and unloading device 3 is reversibly arranged on the rear side of the bed 102, and the loading and unloading device 3 can be horizontally placed in the limit groove 108 when it is turned over in the upward direction of the working platform 1. The loading and unloading device 3 is provided with There is a third sucker device 307, and the third sucker device 307 can absorb the workpiece 4; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com