Tower plate type drying and fermenting device

A fermentation device and tray technology, which is applied in the field of tray-type drying and fermentation devices, can solve the problems of manpower consumption, unstable equipment, high energy consumption, etc., and achieve the effects of not easily deformed, stronger under pressure, and lower power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

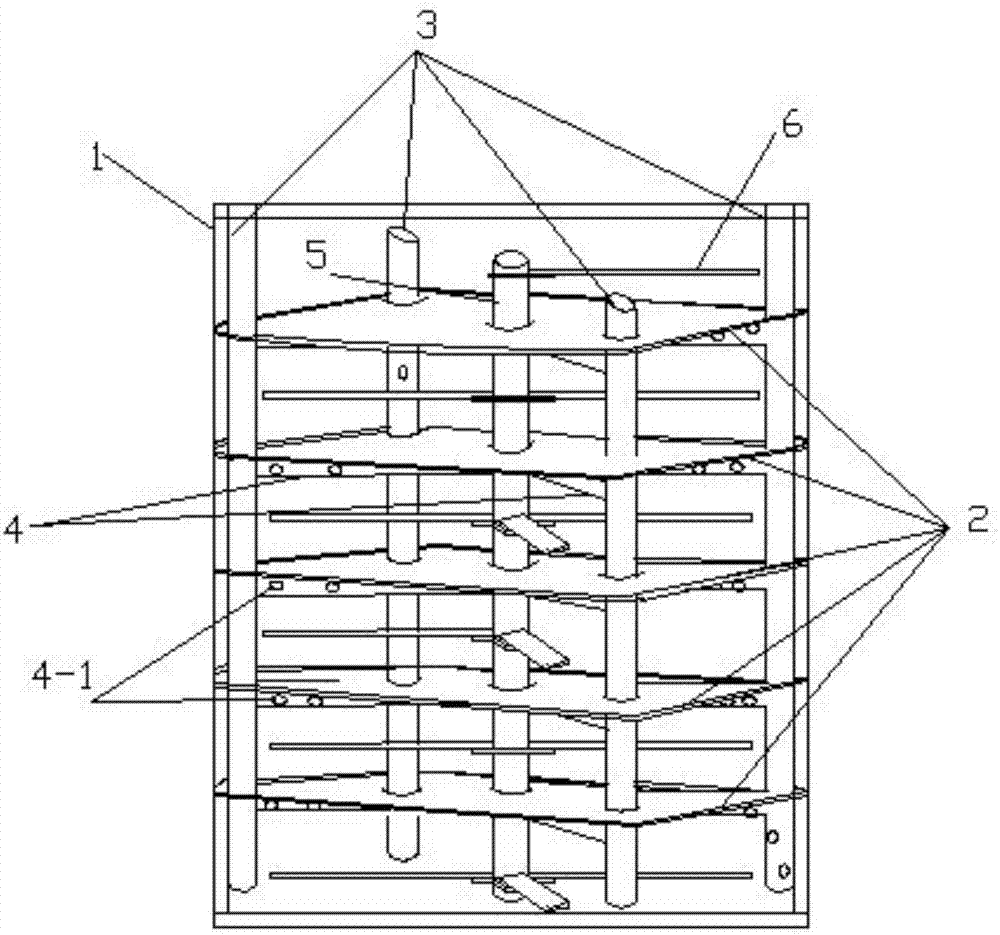

[0018] A kind of tray type dry fermentation device of the present invention, as figure 1 As shown, it includes a tank body 1 for holding sludge, and the inside of the tank body 1 is arranged as a multi-layer structure in the vertical direction, and each layer is used to hold sludge for treatment, and each layer is connected to each other. When the sludge is put in from the top of the tank body 1, a sludge communication channel that communicates sequentially from top to bottom is formed, and each layer supports the sludge during the sludge landing and treatment process; The gas conveying device in 1 is used to convey gas to the sludge.

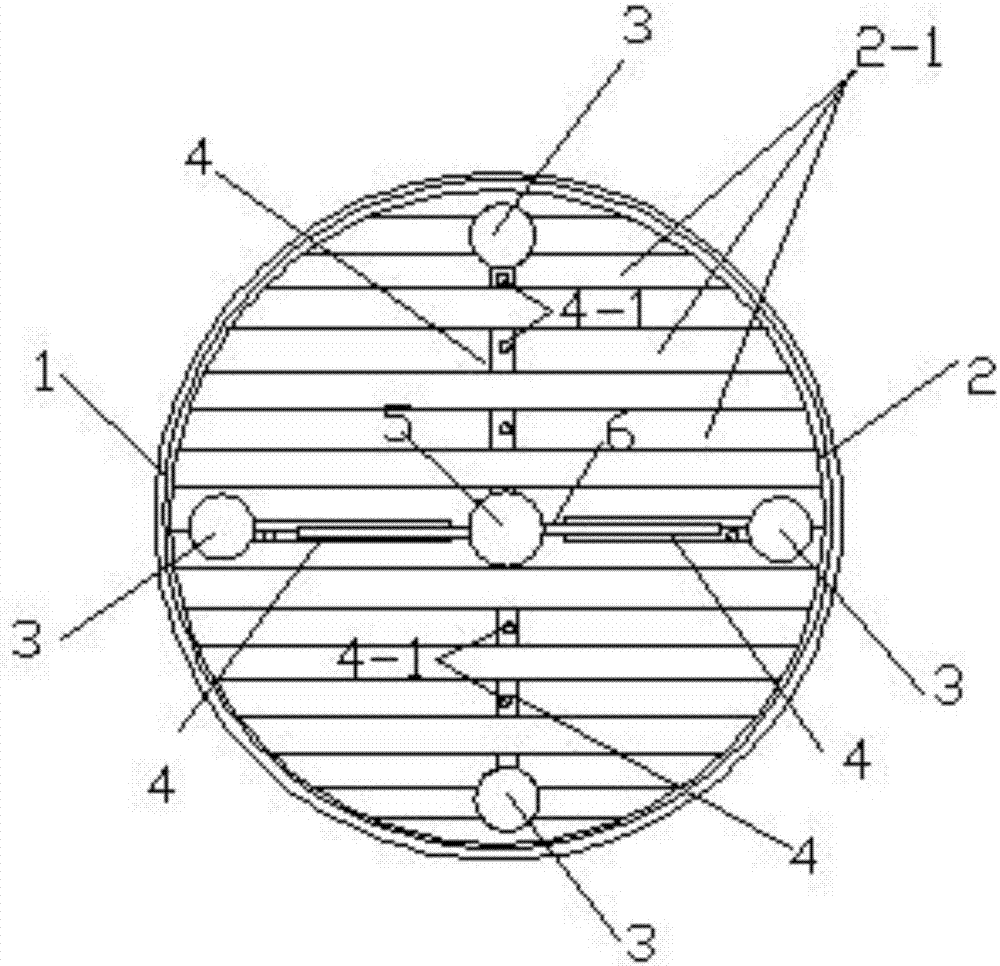

[0019] The multi-layer structure is divided by trays 2 arranged horizontally at intervals up and down. In each layer, the lower tray 2 is also used to support the sludge in the layer; The connecting channel 2-1, so that each column plate 2 and each layer are connected. Such as figure 2 As shown, the connecting channel 2-1 is a vertically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com