Multi-model prediction control method of carbon dioxide after combustion capture system

A predictive control and multi-model technology, applied in the direction of control/regulation system, adaptive control, general control system, etc., can solve the problems of stability degradation and predictive controller control performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Apply the multi-model predictive control method of the present invention to the CO after combustion of a certain 1MW thermal power unit 2 In the simulation model of the capture system, the control goal is to make the CO 2 Capture rate and reboiler temperature track set point for CO 2 Large-scale variable operating conditions of the capture system.

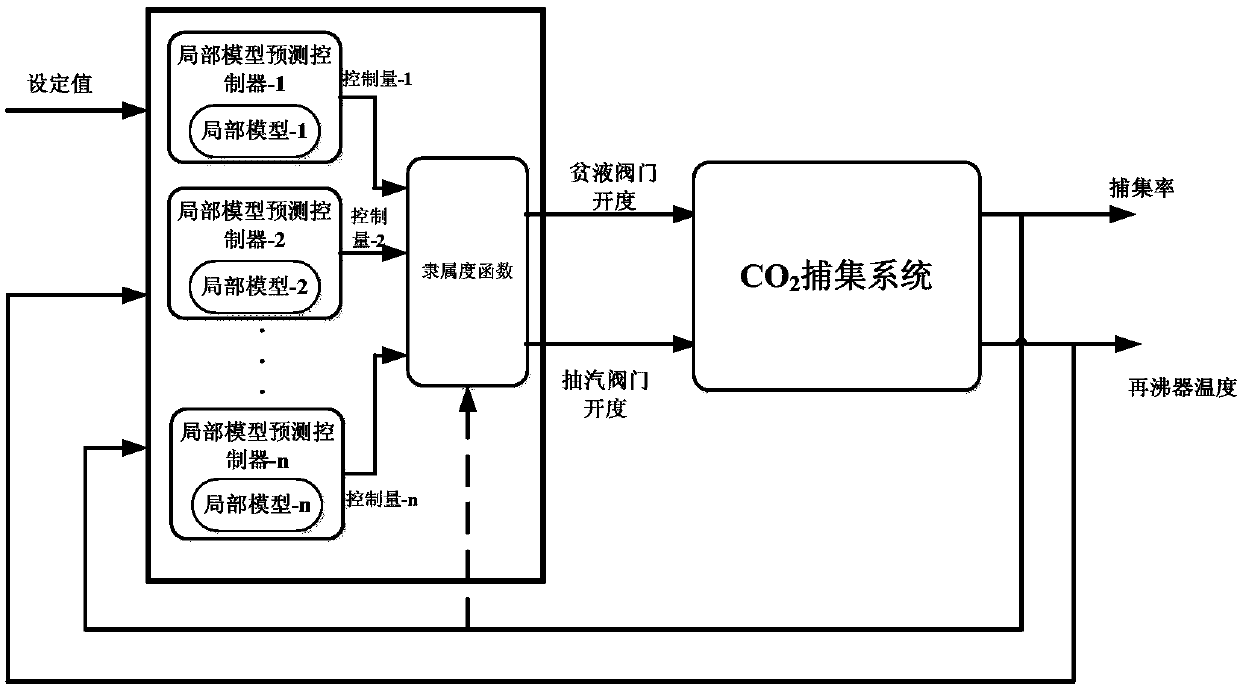

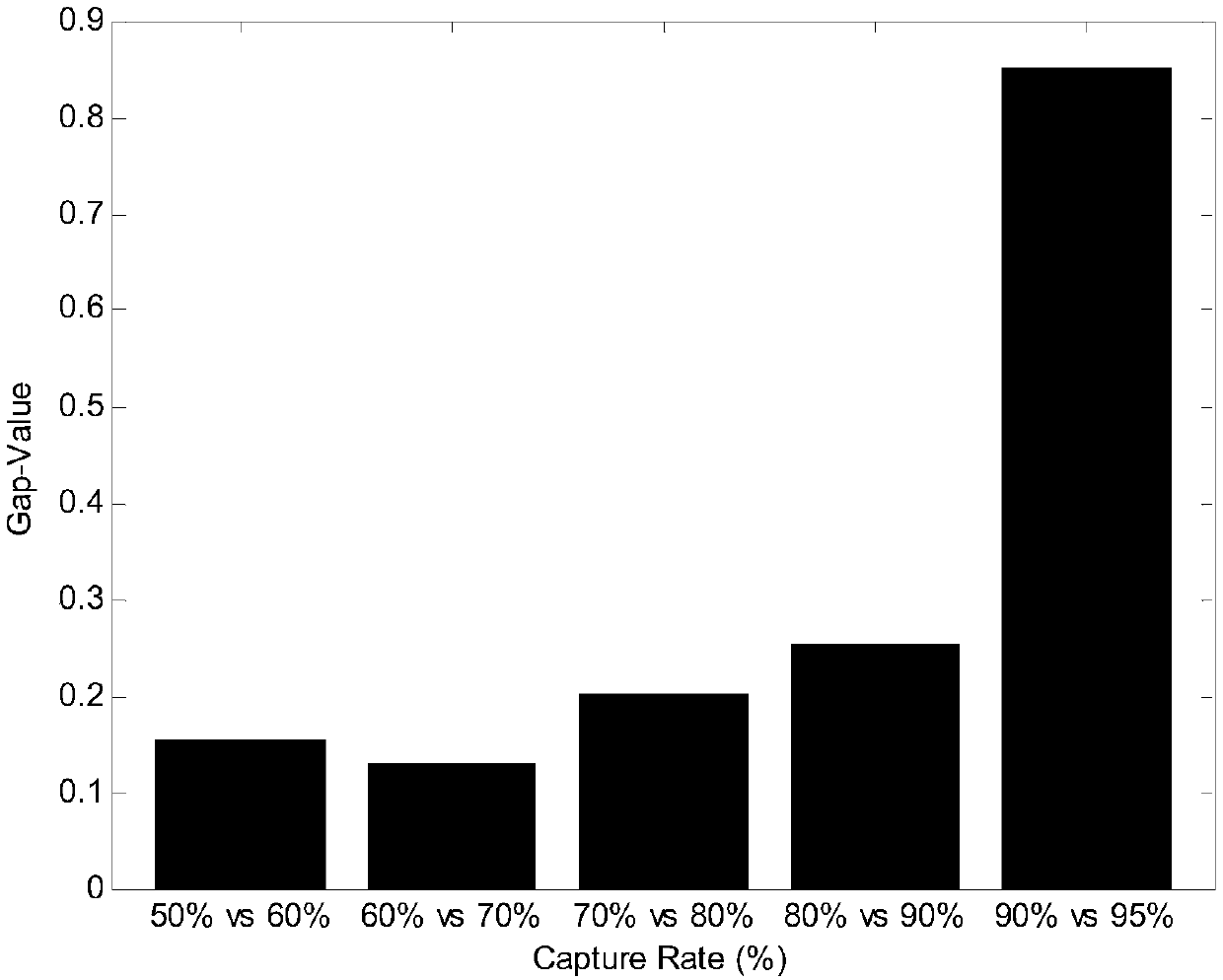

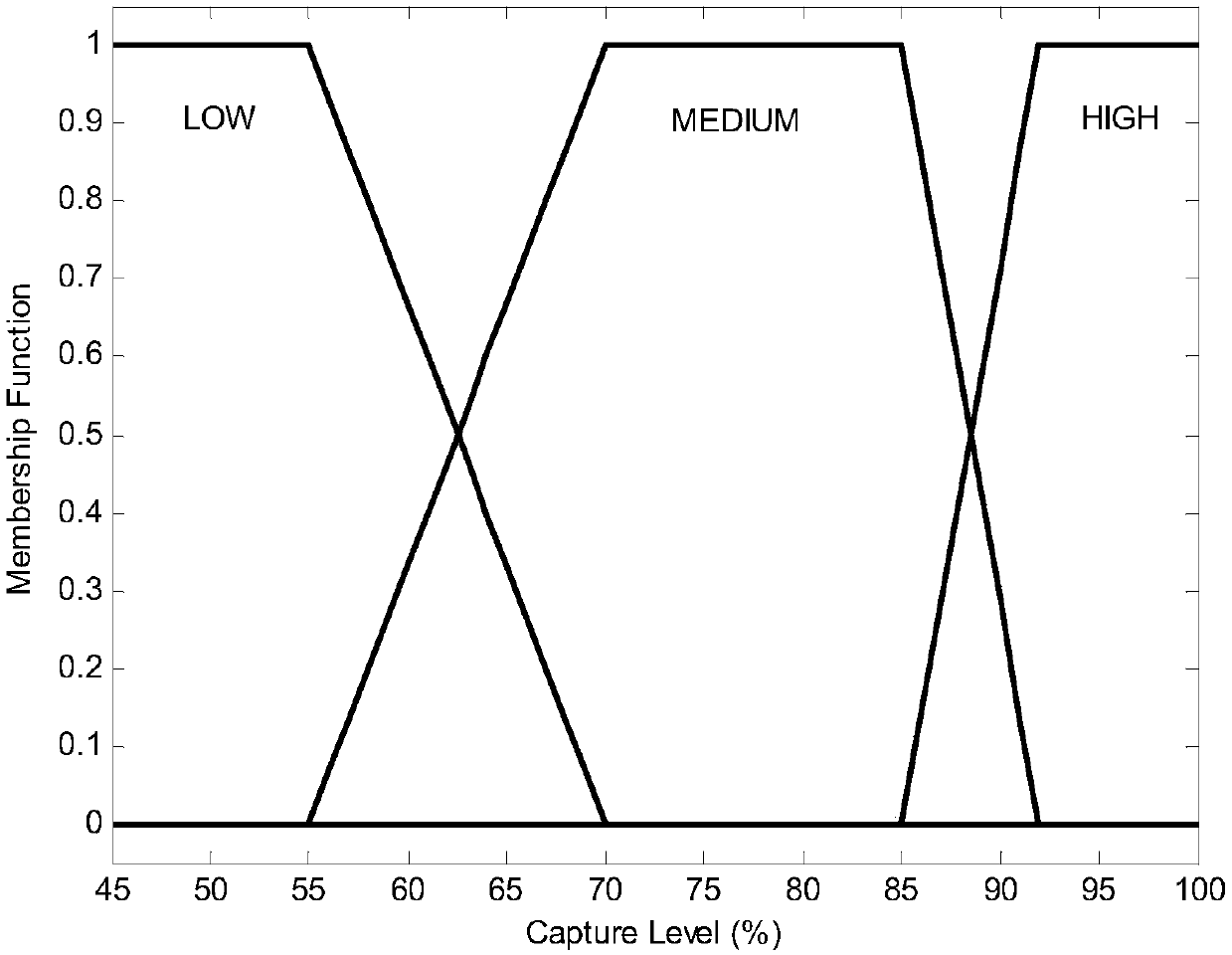

[0064] Post-combustion CO of the present invention 2 A multi-model predictive control method for capture systems based on chemisorption-based post-combustion CO 2 The capture system is the controlled object, the lean liquid valve opening and the steam turbine low-pressure cylinder extraction valve opening are the system control inputs, and the CO 2 The capture rate and reboiler temperature are the output of the system. First, based on the subspace identification method, using the data generated by the system operation, the local state space model of the system is established at different operating points; then the gap mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com