High-level radioactive industrial cobalt source anti-leakage packaging structure and packaging technology

A technology of packaging structure and packaging process, applied in the fields of radioisotopes, radioactive sealed sources, and nuclear technology applications, can solve problems such as the generation of cobalt-containing radioactive aerosols, the peeling of the coating on the surface of cobalt particles, and the complicated welding process of stainless steel, so as to facilitate recycling and reuse. Utilize, reduce the risk of leakage, increase the effect of product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

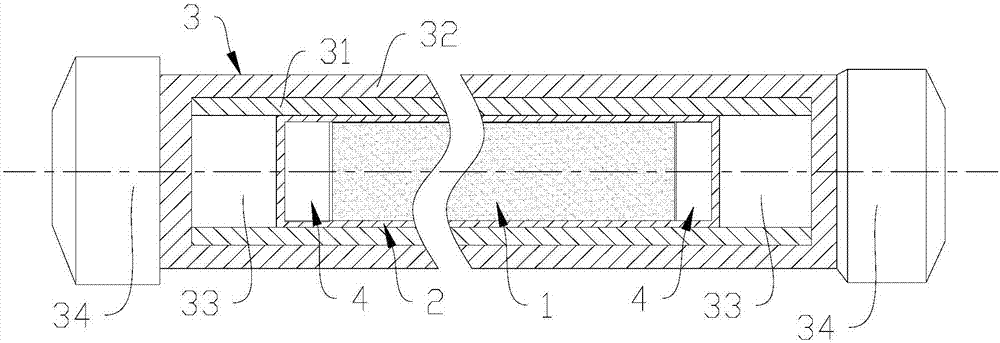

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0026] like figure 1 As shown, the highly radioactive industrial cobalt source leakage-proof packaging structure in a preferred embodiment of the present invention includes a glass sealing body 2 sealed and sealed for cobalt particles 1, and a metal sealing structure 3 sealed outside the sealing body 2, cobalt Particle 1 is usually high activity cobalt-60.

[0027] Add a layer of sealing body 2 made of low melting point material outside the cobalt particle 1. By utilizing the low melting point characteristic of the sealing body 2, when the cobalt particle 1 is melted and sealed, the sealing time is short, and the melting temperature is lower than that of stainless steel, which can ensure that the cobalt particle 1 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com