Compression moulding device for molasses-mineral-urea block and using method of compression moulding device

A technology for pressing and forming and licking bricks is applied in the field of pressing and forming devices for licking bricks, which can solve the problems of low pressing efficiency and complex structure, and achieve the effects of high pressing efficiency, simple operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

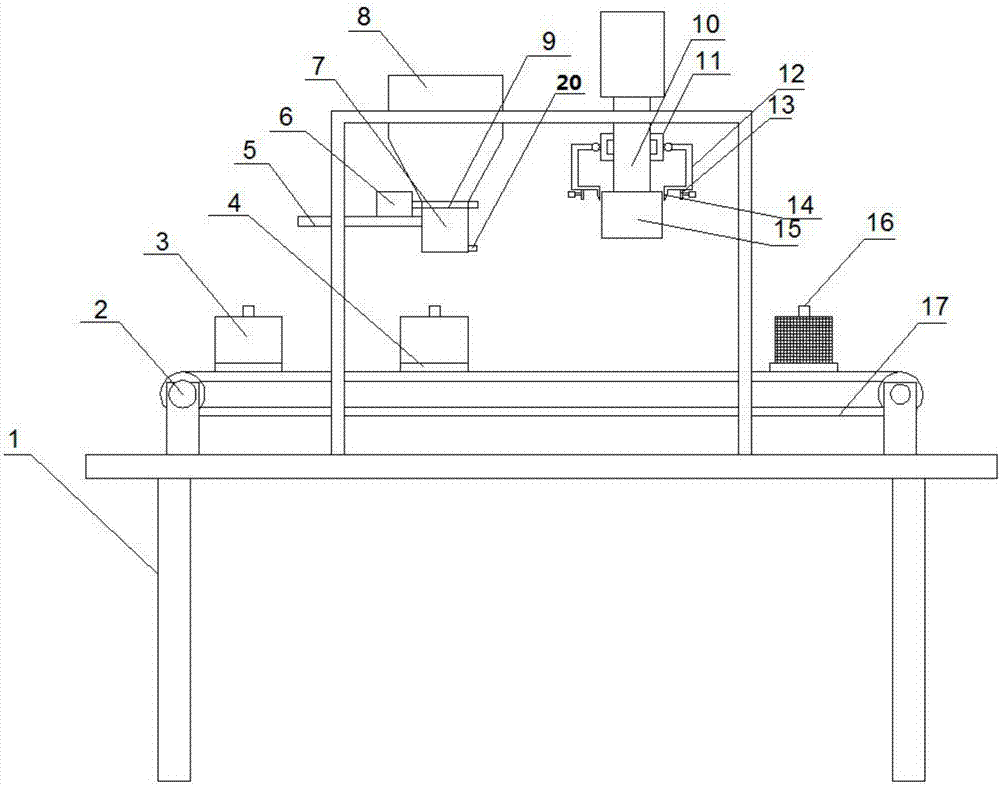

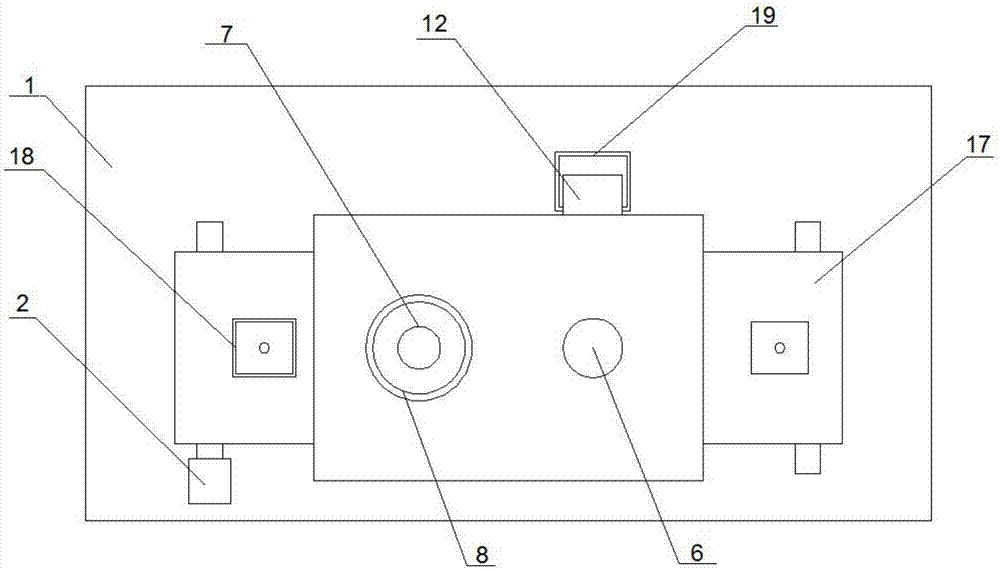

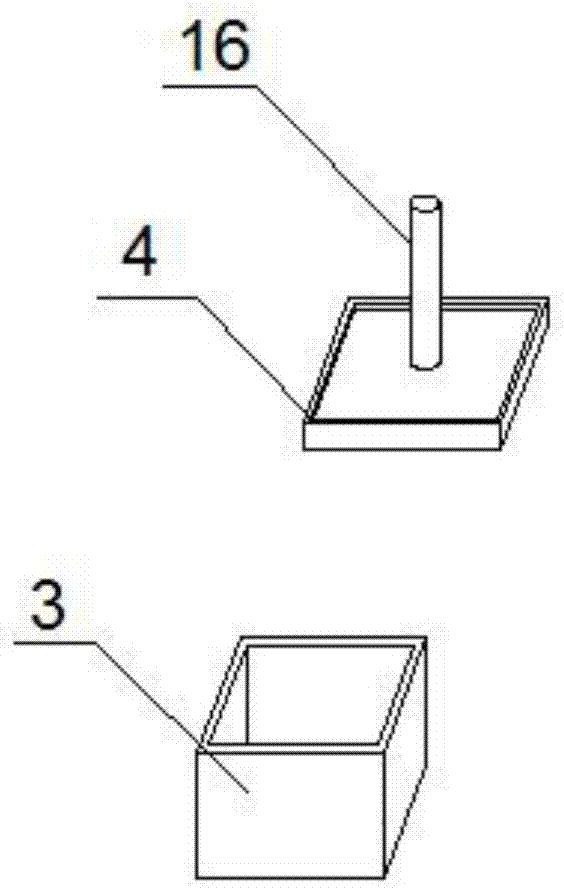

[0021] like Figures 1 to 3 As shown, this embodiment provides a pressing and forming device for brick licking processing, including a bracket, and a conveying mechanism driven by a motor is provided on the support, a brick licking mold is placed on the conveying mechanism, and a fixed The discharge mechanism and the pressing mechanism on the bracket, the pressing mechanism includes a connecting rod driven by a cylinder, a pressure block is fixed at the end of the connecting rod, and mounting plates are arranged on both sides of the connecting rod, and the mounting plate is embedded Combined with a grabbing mechanism driven by an air cylinder.

[0022] Place the mold on the conveying mechanism, add raw materials into the mold through the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com