Ultrasonic cleaner

An ultrasonic cleaner technology, applied in the field of ultrasonic cleaners, can solve the problems of steel wire surface corrosion resistance decline, steel wire surface gap corrosion, large workshop area, etc., and achieve the effects of low cost, increased strength and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

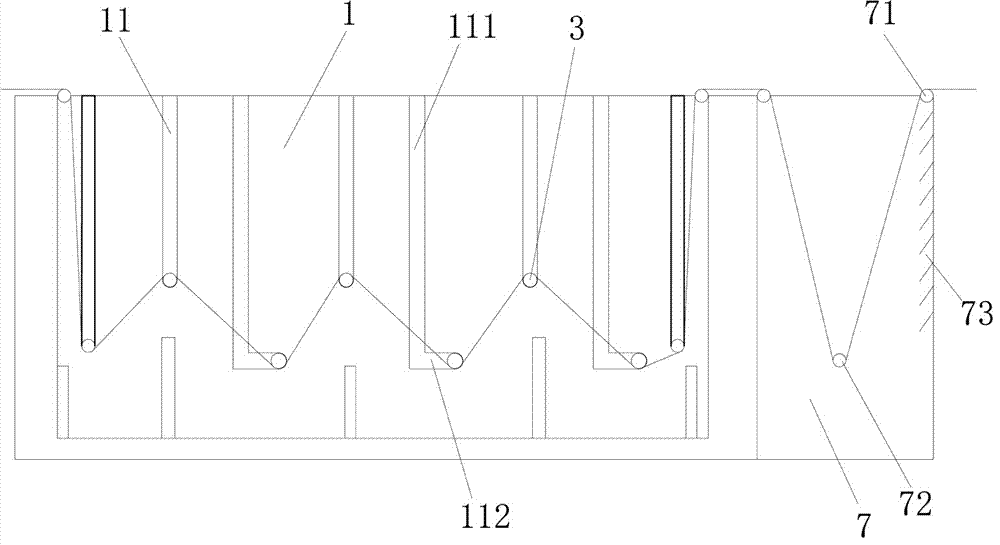

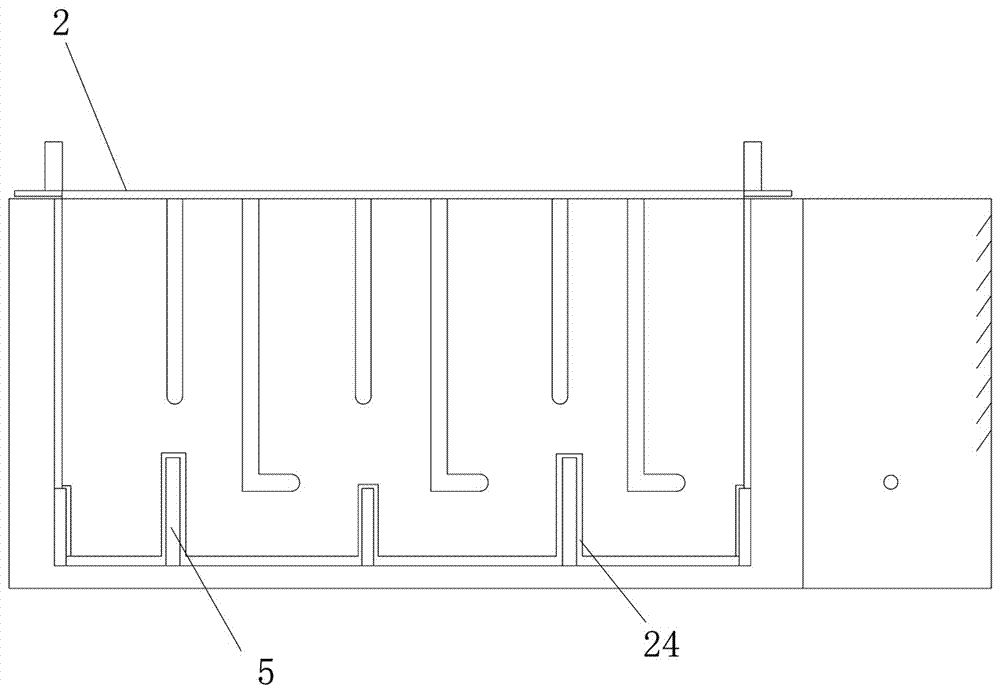

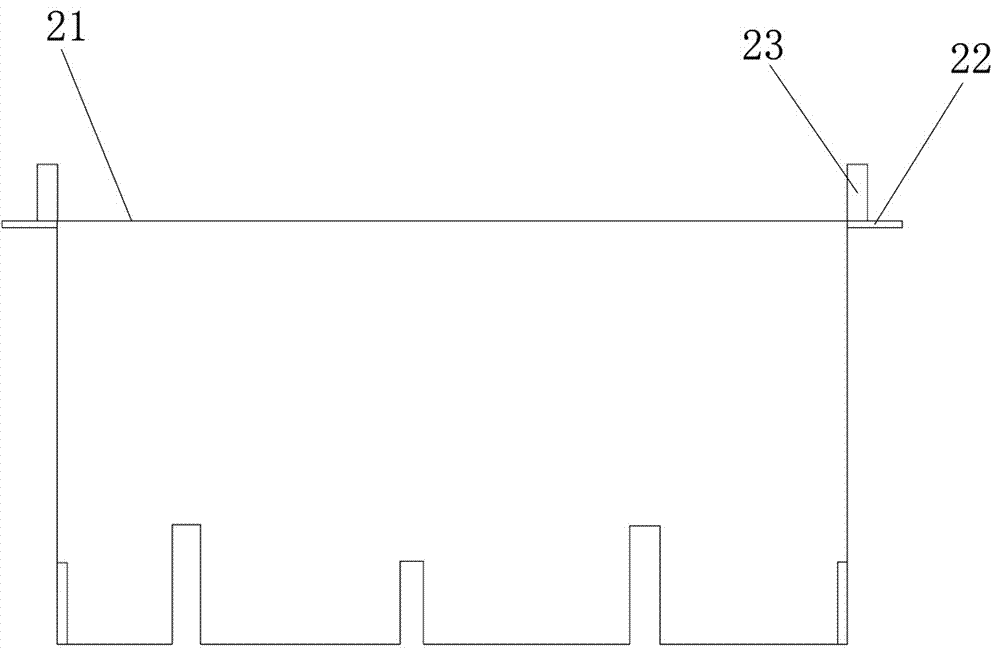

[0035] An ultrasonic cleaner, the ultrasonic cleaner includes a cleaning tank 1 with ultrasonic vibration, a filter screen frame 2 that can be erected in the cleaning tank, and a number of transfer rollers 3 that can be arranged in the cleaning tank; The filter screen frame includes a frame body 21 and a frame 22 located on the outer edge of the top of the frame body, and a hoisting ring 23 is arranged on the frame body.

[0036] A group of opposite tank walls on both sides of the cleaning tank are correspondingly provided with several roller slots 11 for cooperating with the two ends of the conveying rollers. It includes an introduction groove 111 that extends upwards to the top of the cleaning tank and is open at the upper end to form an insertion port. At least part of the roller insertion groove also includes a locking groove 112 that communicates with the bottom of the introduction groove and forms a knuckle with the introduction groove. .

[0037] The roller fitting gro...

Embodiment 2

[0041] The difference from the above embodiment is that every two adjacent conveying rollers form a group, and the two ends of the two conveying rollers are connected with connecting rods 4 . The conveying rollers of the above structure are set in pairs, and each group is set up and down. The steel wire reciprocates up and down in the washer, which lengthens the distance in the washer and improves the cleaning efficiency. It will not run up, so only one introduction groove is needed. The introduction groove is a long groove, and the transmission roller is not easy to fall out and easy to install. The locking groove of the lower groove can hold the transmission roller in this position and not along the introduction The groove runs upwards and escapes from the groove, and the conveying roller is also driven to press into the locking groove during the traveling process of the steel wire.

[0042] The connecting rod includes a rod body 41 and a collar 42 fixed at both ends of the ...

Embodiment 3

[0045] The difference from the above-mentioned embodiment is that the wall of the cleaning tank is provided with several frame bars 5 that protrude into the tank, and the filter screen frame is provided with a frame bar that is formed by the filter screen indenting into the frame. The shelf groove 24 that bridge connects.

[0046] The setting of the frame makes the cleaning tank fully drive the vibration of the filter screen frame, thereby realizing the follower effect, and the entire filter screen frame also undergoes ultrasonic vibration to improve the ultrasonic cleaning efficiency. And the frame bar improves the stability of the filter screen frame, and the frame groove improves the strength of the filter screen frame. The upper end of the rack tank is sealed to form a horizontal rack surface, the bottom end of the rack bar is connected to the bottom plate of the cleaning tank, and the upper end is lower than the top of the cleaning tank.

[0047] The frame bars are divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com