Automatic pressure steel pipe welding line leveling welding device and method

A pressure steel pipe, automatic leveling technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as fracture of the welding surface of the nozzle, uneven pressure bearing of the pipe wall, and irregular shape of the nozzle, so as to ensure the welding Quality and precision, improvement of shaping effect, effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

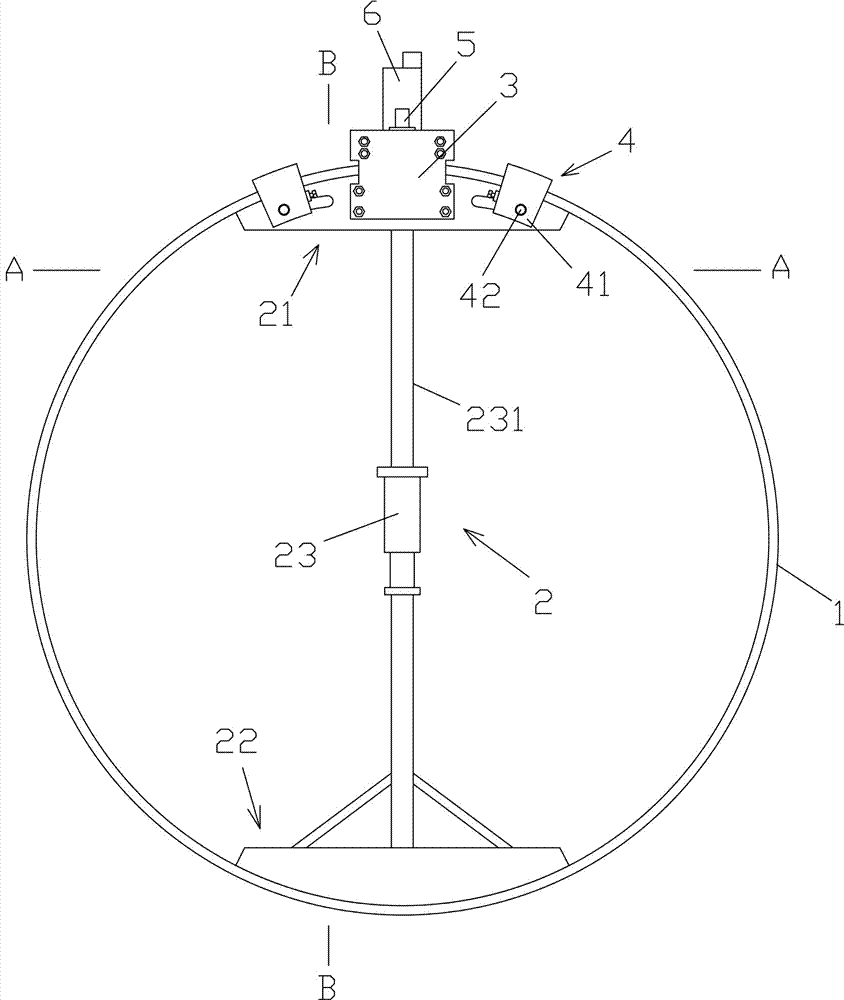

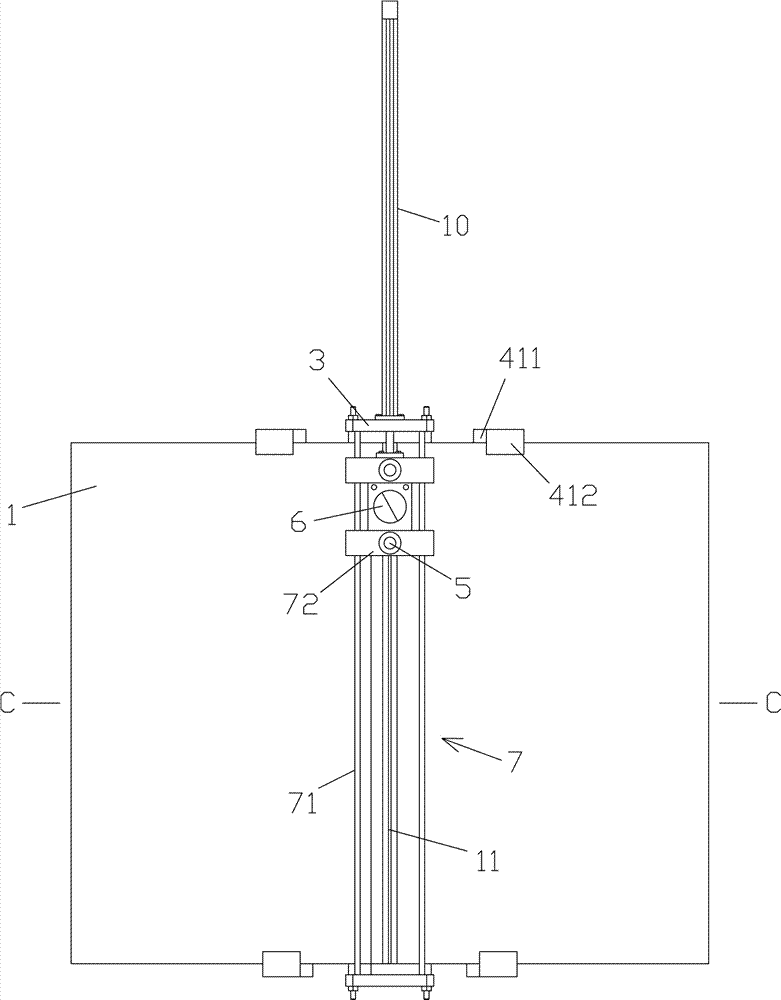

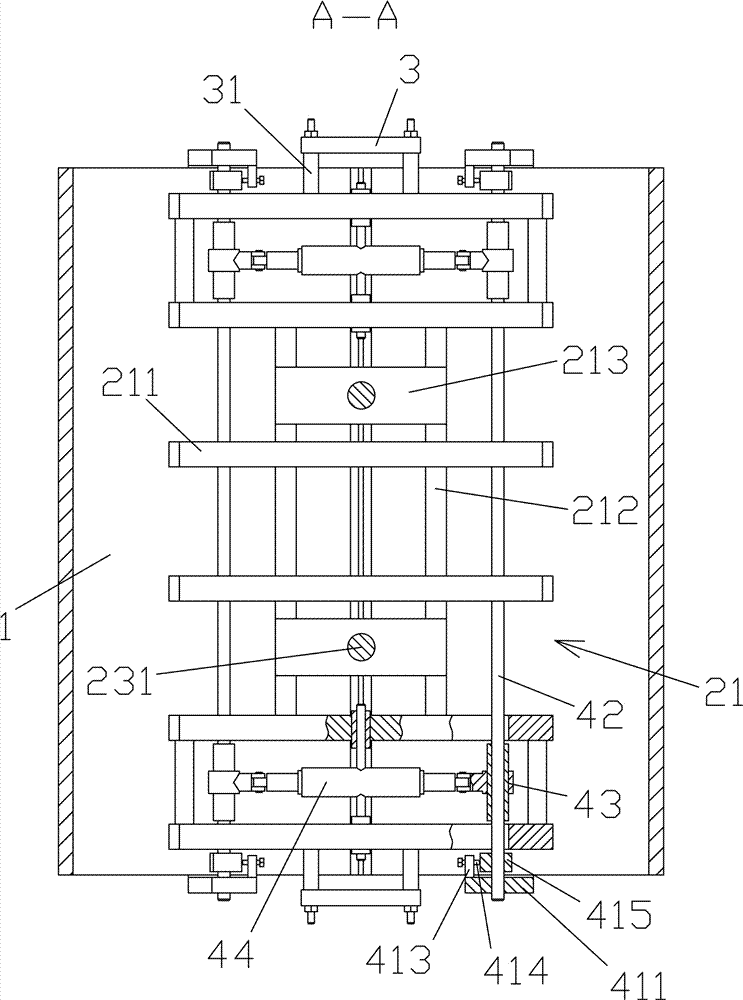

[0036] Such as Figures 1 to 7 As shown, an automatic leveling welding device for penstock welds includes a telescopic frame 2 arranged inside the penstock and a sliding mechanism 7 arranged outside the penstock. The telescopic frame 2 is detachably connected, and a welding machine 6 and two groups of pressure tube mechanisms 5 are installed on the sliding mechanism 7, and the two groups of pressure tube mechanisms 5 are respectively arranged on both sides of the welding machine 6;

[0037] The telescopic frame 2 includes a top frame 21, a bottom frame 22 and a plurality of first oil cylinders 23, the top frame 21 is connected with the bottom frame 22 through a plurality of first oil cylinders 23, the top surface of the top frame 21 and the bottom surface of the bottom frame 22 are arc surfaces , two connecting plates 3 are respectively connected on both sides of the top frame 21, and the seam of the pressure steel pipe to be welded is located between the two connecting plates...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap