Transfer printing fixing device

A fixing device and pad printing technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of high production cost, damage to the 90-degree rotating cylinder, and crushing of the protruding end of the outer frame, so as to achieve low loss, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with each accompanying drawing, the present invention is described in detail.

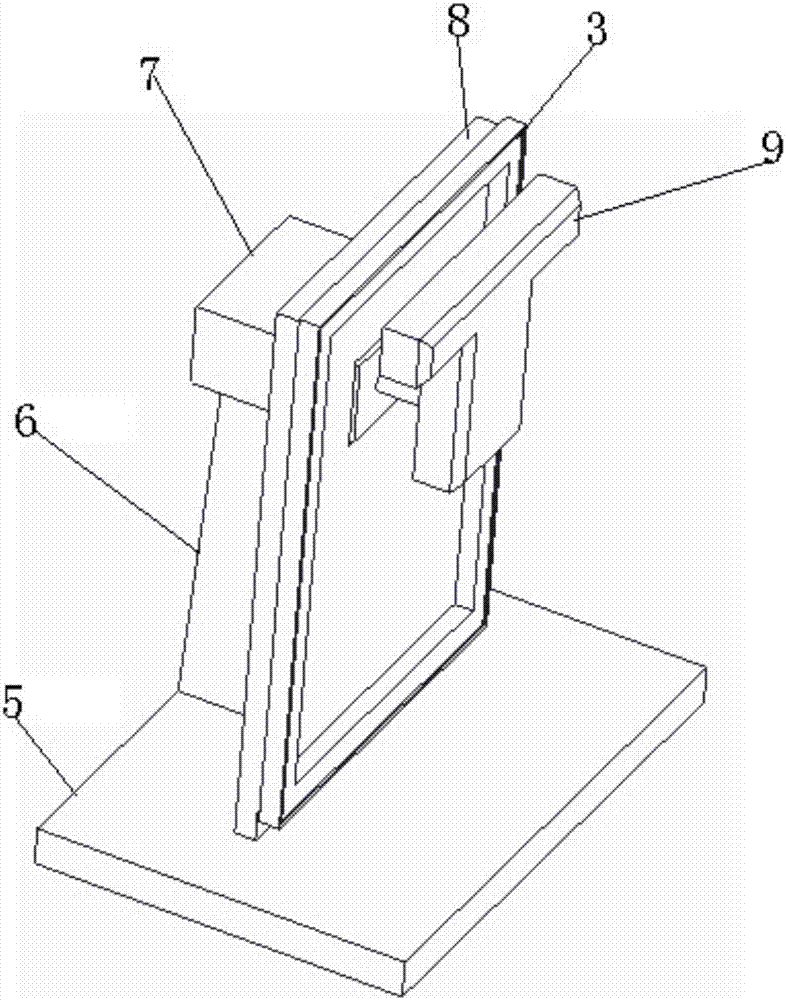

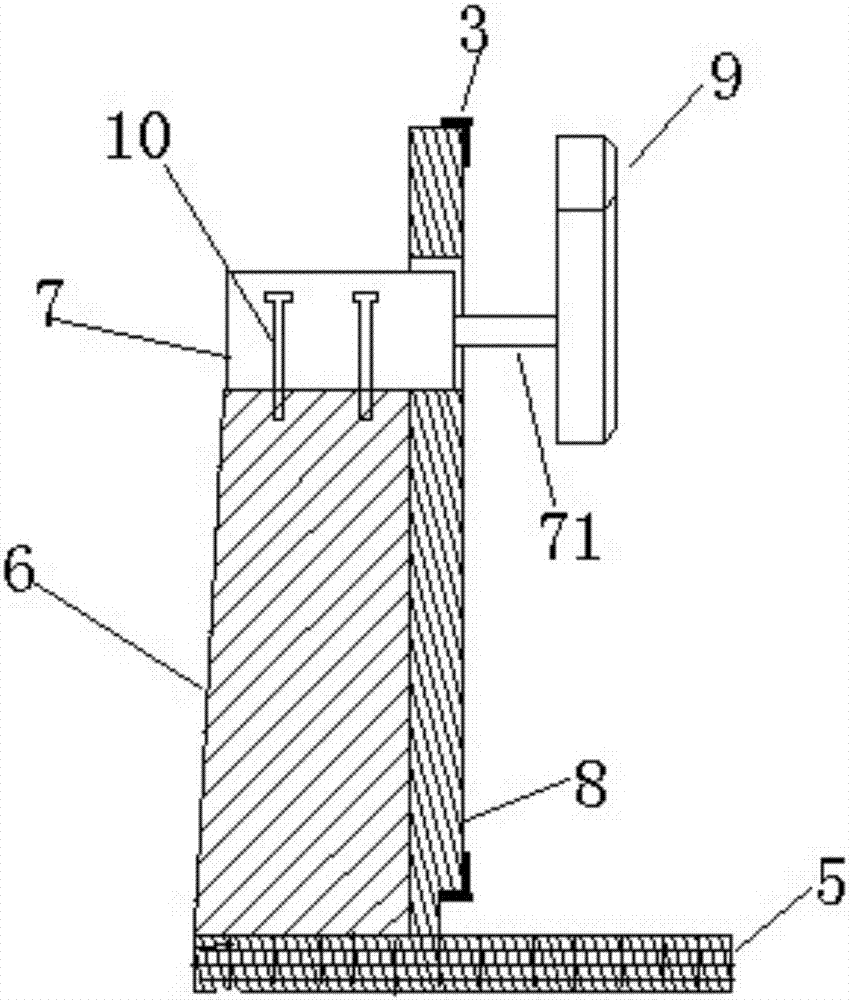

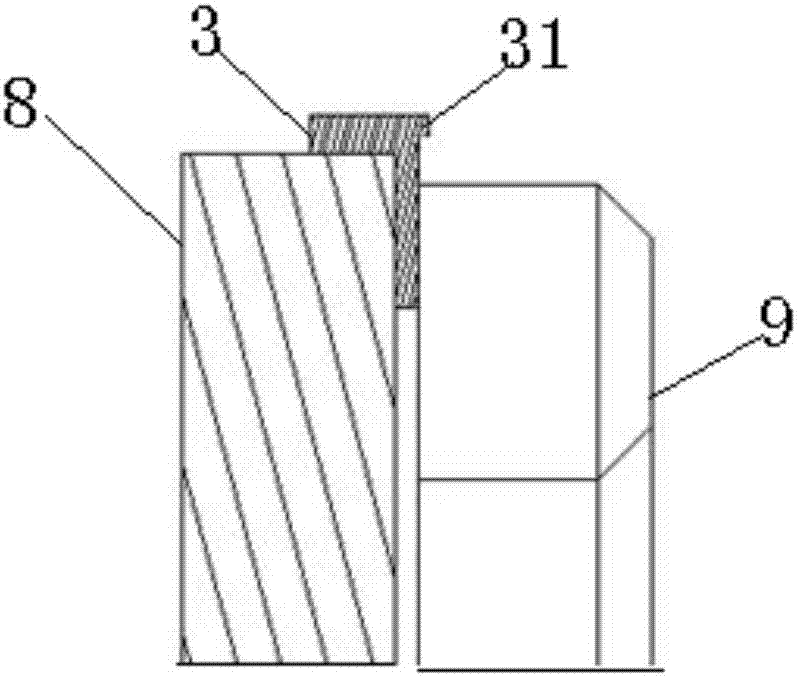

[0029] as attached figure 1 , attached figure 2 and attached image 3 As shown, a pad printing fixing device, a pad printing fixing device, including a substrate 8, a press-attached handle, is characterized in that it also includes a parallel cylinder 7, the substrate 8 is in a vertical state, and a through hole is provided on the substrate 8. The parallel cylinder 7 is installed on the support 6, and the piston rod 71 of the parallel cylinder 7 vertically passes through the through hole of the base plate 8 and connects with the press-attached handle.

[0030] When in use, first put the outer frame 3 on the base plate 8, start the parallel cylinder 7, and the piston cylinder of the parallel cylinder 7 starts to shrink, driving the pressing handle to move closer to the base plate 8, when the pressing handle is attached to the outer frame 3 , the outer frame 3 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com