A ship with an energy-saving acceleration mechanism

A technology for ships and rotating motors, applied in ships, ship construction, ship propulsion, etc., can solve problems affecting ship speed, potential safety hazards, and speeding up of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

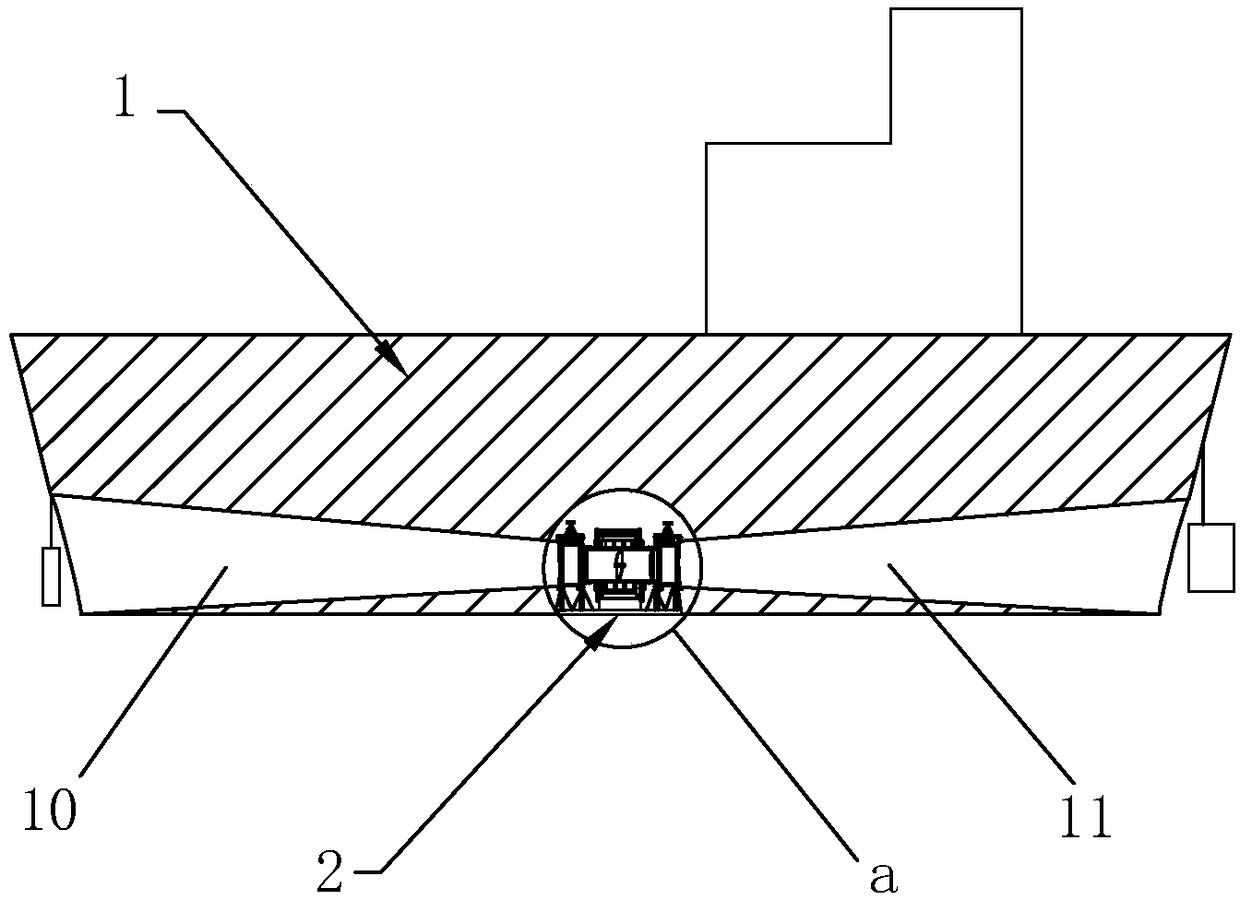

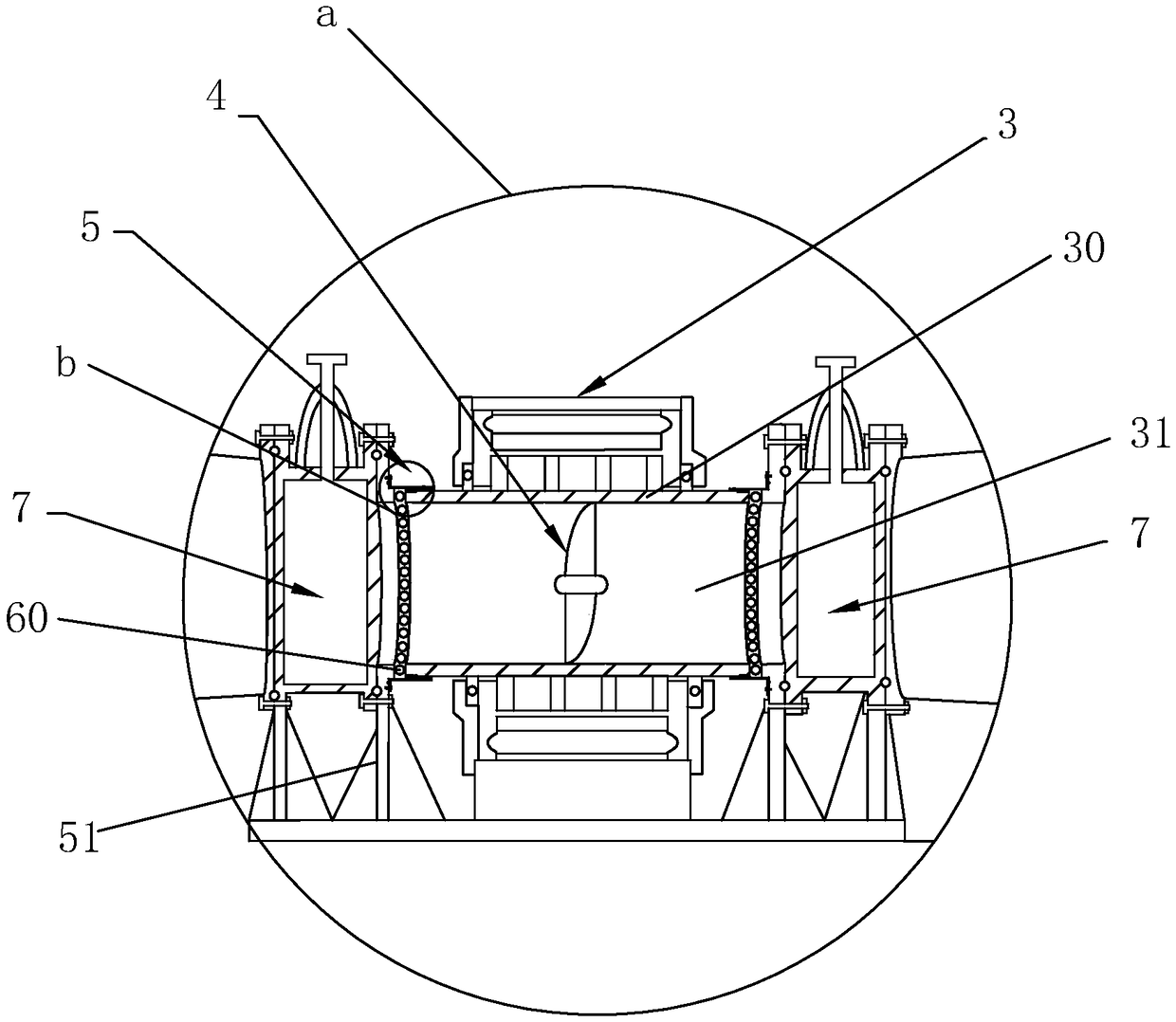

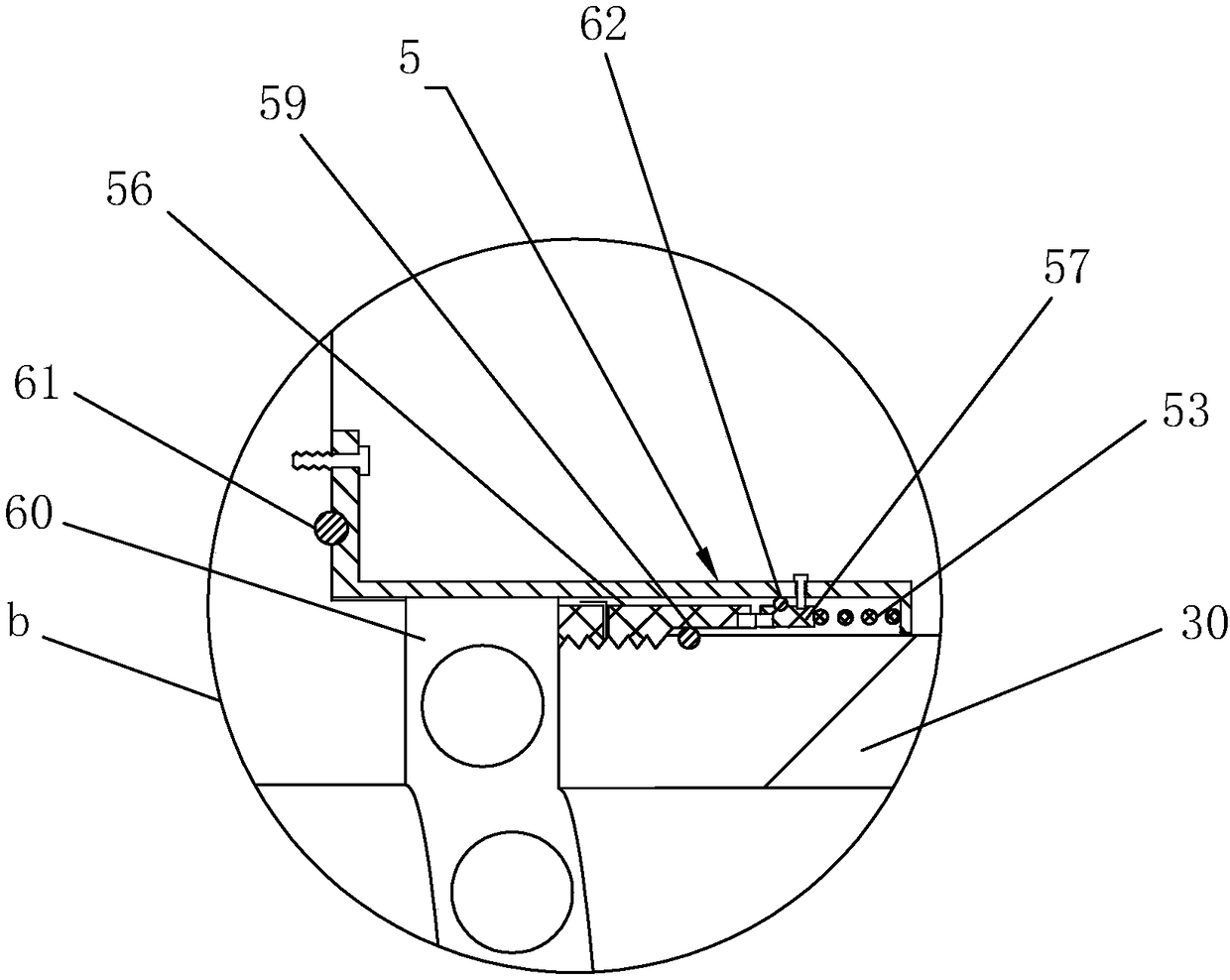

[0018] refer to Figure 1 to Figure 5 A ship embodiment with an energy-saving acceleration mechanism of the present invention will be further described.

[0019] A ship with an energy-saving acceleration mechanism 2, comprising a hull 1, an acceleration mechanism 2 is arranged in the hull 1, the acceleration mechanism 2 includes a motor device 3, and the motor device 3 includes a rotating motor shaft 30, and the rotating motor shaft 30 A through-cavity 31 is provided inside, and an impeller 4 is arranged in the said through-cavity 31, and one end of the rotating motor shaft 30 is connected with a water inlet channel 10, and the water inlet channel 10 is extended to the bow of the hull 1, and the The other end of the rotating motor shaft 30 is connected with a water outlet channel 11, and the water outlet channel 11 is extended to the stern of the hull 1, and a sealing assembly 5 is arranged between the rotating motor shaft 30, the water inlet channel 10, and the water outlet c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com