Sealed conveying device for fully automatic stacking of magnetic material billets

A conveying device and magnetic material technology, which is applied in the field of conveying magnetic material blanks, can solve the problems of difficulty in achieving no oxygen and nitrogen, oxygen infiltration, low magnetic energy, etc., achieve fully automatic stacking and conveying, avoid labor costs, Avoid low magnetic energy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

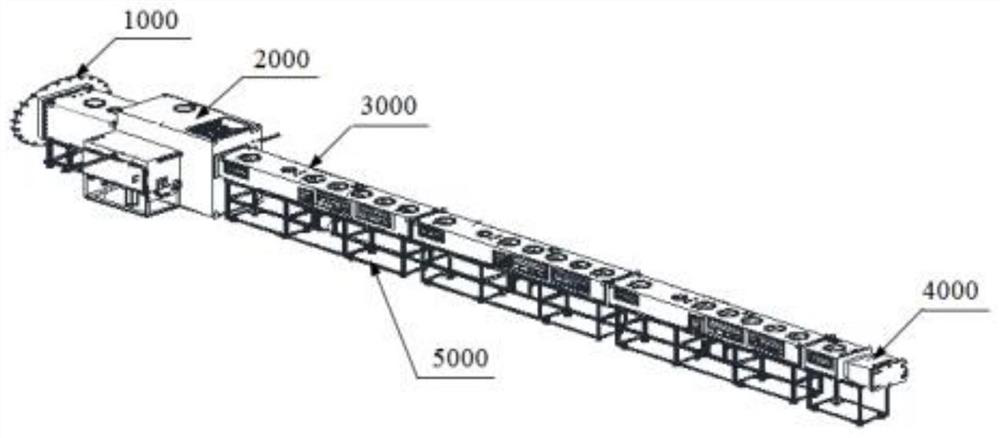

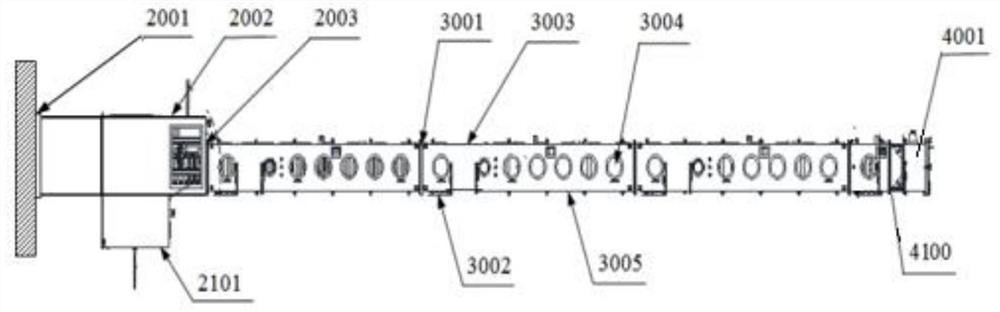

[0054] see figure 1 , 2 , a fully automatic sealing conveying device for stacking magnetic material blanks, which includes stacking box stacking cabins 2000 connected in series, a plurality of conveying main channel cabins 3000, manual box feeding cabins 4000, and a box for supporting the manual box feeding cabin and the cabin box support 5000 of the main channel cabin for conveying; the left end of the box stacking cabin 2000 has an output interface 2001 connected with the sintering furnace 1000, and the right end has an input interface 2003 connected with the main channel cabin 3000 for conveying;

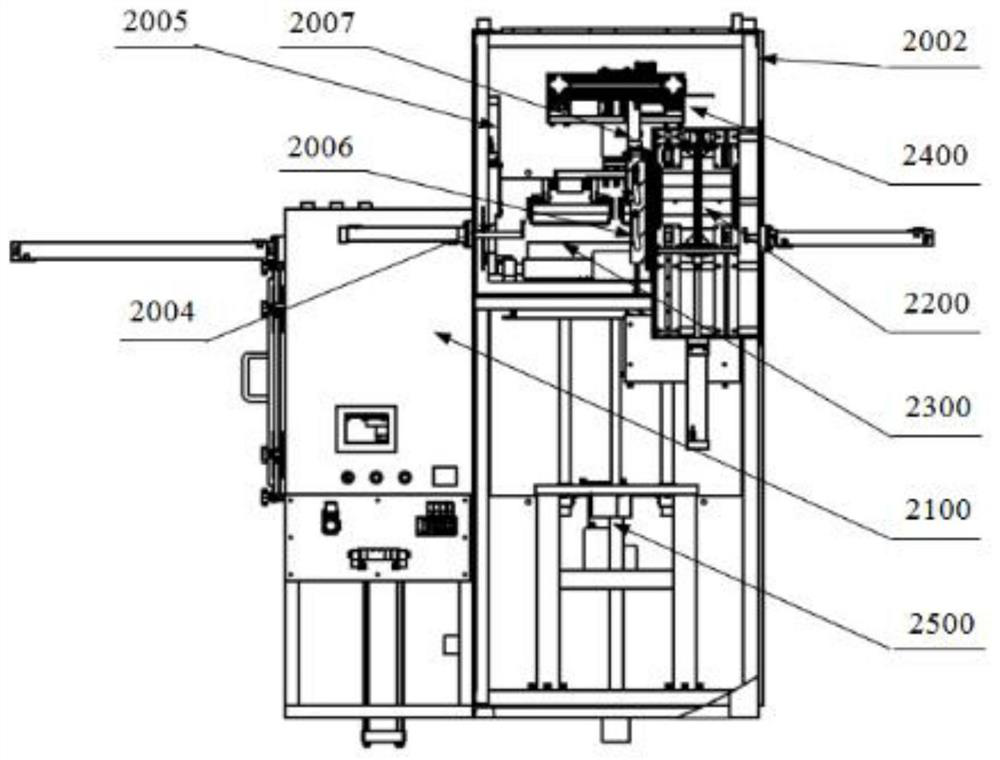

[0055] see image 3 , the code box stacking box cabin 2000 includes an ink cartridge base pushing mechanism 2100, a code box stacking box main box body 2002 and an ink cartridge cover pushing mechanism 2200 arranged in the code box stacking box main box body 2002, ink cartridges and ink cartridge cover arrangements Mechanism 2300, Manipulator Mechanism 2400, Elevator Mechanism ...

Embodiment 2

[0068] see Figures 1 to 18 , the present invention has a plurality of channel delivery cabins 3000 that are sealed and connected in the sealed delivery device for fully automatic stacking of magnetic material blanks, and each channel delivery cabin 3000 is connected to a fully automatic magnetic powder press through a press interface (3002) on its side. Corresponding connection; this embodiment takes the sealed conveying device of the fully automatic stacking magnetic material blank with four channel conveying cabins 3000 as an example:

[0069] Connect the feeding outlets of the four fully automatic magnetic powder presses to the press interface 3002 of the four-channel conveying cabin 3000 in the sealed conveying device for fully automatic stacking of magnetic material billets respectively; the pressure gauge interface 4002 is equipped with a reading pressure gauge and an alarm The controller; the manual nitrogen charging and oxygen exhausting interface 4008 is plugged into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com