Vehicle-mounted movable multifunctional weight hoisting equipment

A kind of hoisting equipment and multi-functional technology, applied in hoisting device, clockwork mechanism, etc., can solve the problems of affecting the efficiency of transportation, high labor intensity of workers, and large occupation, so as to facilitate installation and disassembly and reduce labor intensity of workers , easy to manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

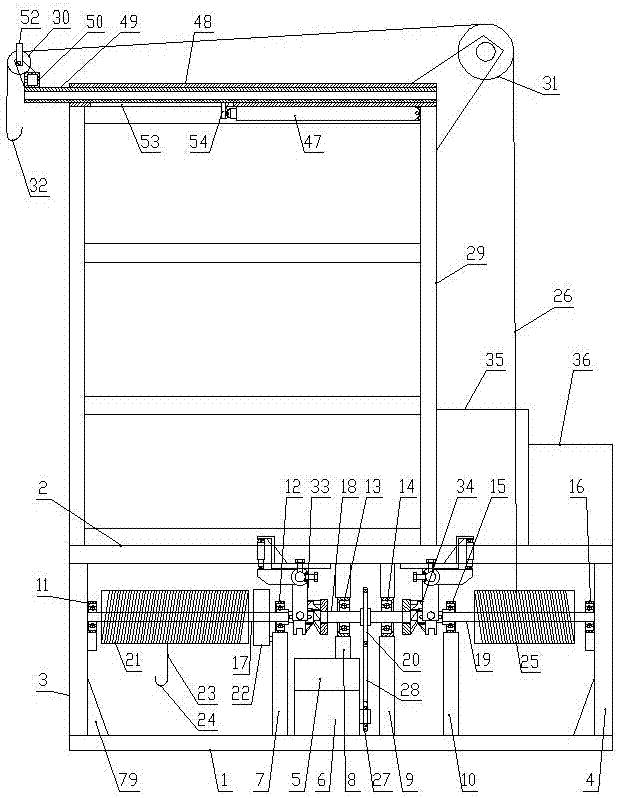

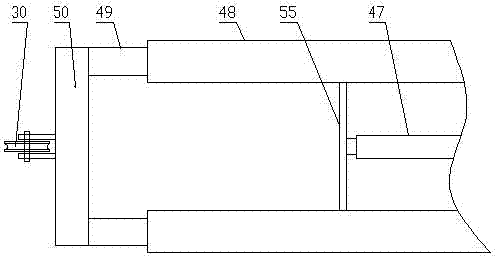

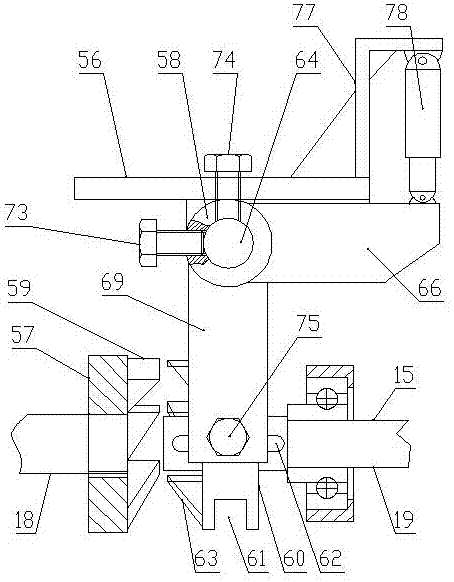

[0035] Such as Figure 1-Figure 7 As shown, the present invention comprises a lower frame 1 and an upper frame 2 arranged horizontally, the left side and the right side between the lower frame 1 and the upper frame 2 are respectively fixedly provided with a left frame 3 and a right frame 4, and the lower frame 1 A drive motor 5 and a gearbox 6 are provided, and the upper surface of the lower frame 1 is provided with a first support frame 7, a second support frame 8, a third support frame 9 and The fourth support frame 10, wherein the top of the second support frame 8 and the third support frame 9 are fixedly connected with the lower surface of the upper frame 2, the left frame 3 right side is provided with a first bearing seat 11, and the first support frame 7 is provided with The second bearing seat 12, the second support frame 8 is provided with the third bearing seat 13, the third support frame 9 is provided with the fourth bearing seat 14, the fourth support frame 10 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com