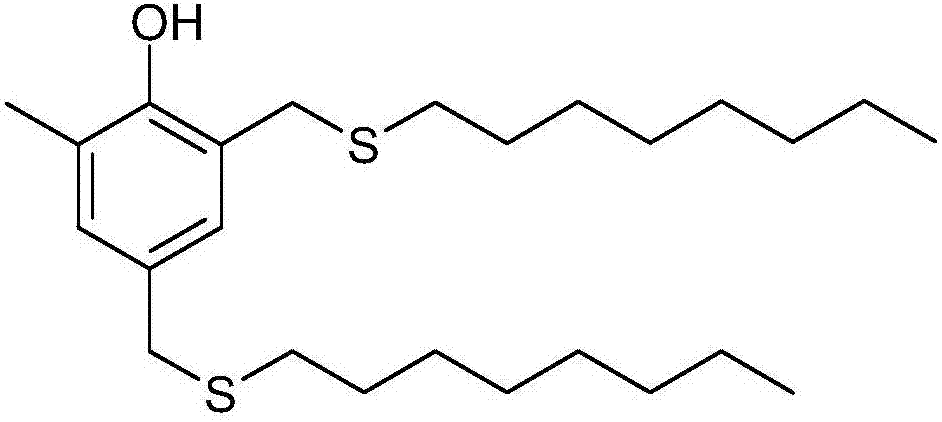

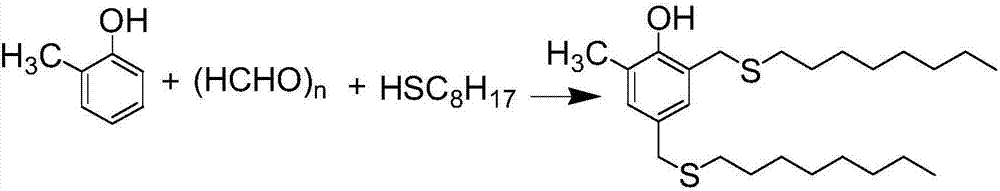

Method for purifying antioxidant 2,4-di(n-octyl sulfur methylene)-6-methylphenol

A purification method and technology for antioxidants, which are applied in the field of purification of antioxidants, can solve problems such as color and product odor, and achieve the effects of high quality and simple technical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

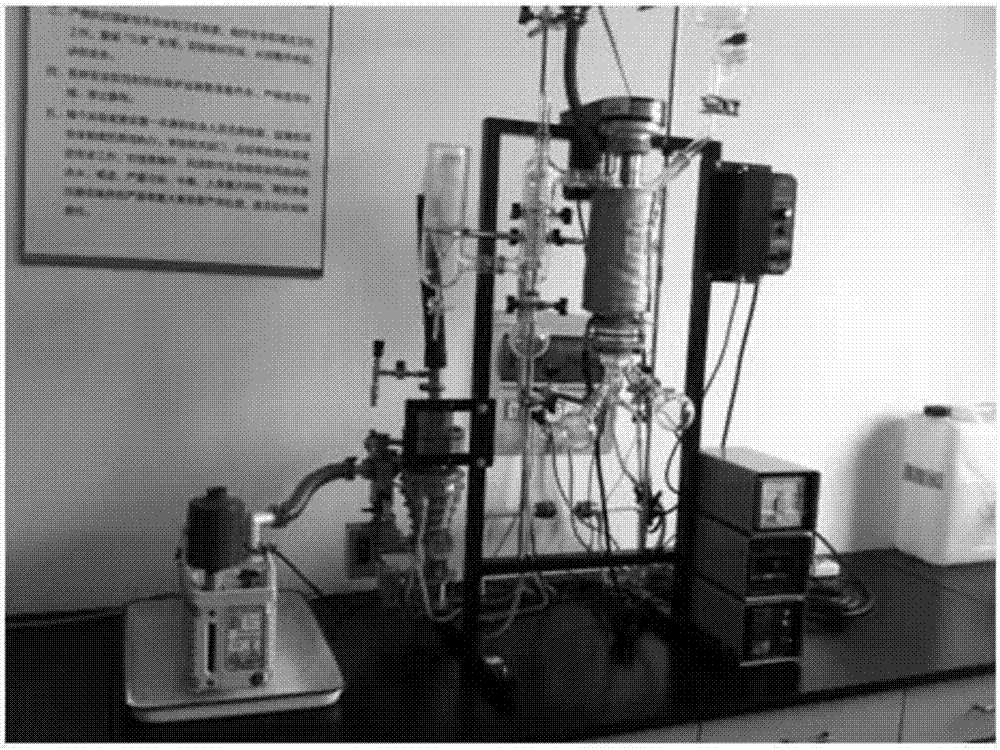

[0024] The experiment used the PL-60220 molecular distillation device produced by POPE Company of the United States, as shown in the accompanying drawing. All parts of the whole set of equipment are connected well, and 245.01g of crude product is added in the feed tank. Close all passages to the atmosphere. Turn on the corresponding power supply, and the cooling water of the condenser plate and the cold well condenser.

[0025] Turn on the vacuum system, set the temperature of the heating plate, the preheating temperatures of the feed tank materials are 80°C and 50°C respectively, and the rotating speed of the rotary wiper is 380r / min. When the vacuum degree is maintained at about 1.33kPa, the raw materials are added dropwise, and after 3 minutes, the product flows out from the heavy component outlet, maintaining a stable drop rate. After 45 minutes, the dropwise addition of the material was completed. The molecular distillation device continued to operate for 15 minutes. ...

Embodiment 2

[0028] The experiment used the PL-60220 molecular distillation device produced by POPE Company of the United States, as shown in the accompanying drawing. All parts of the whole set of equipment are connected well, and 135.0g of crude product is added in the feeding tank. Close all passages to the atmosphere. Turn on the corresponding power supply, and the cooling water of the condenser plate and the cold well condenser.

[0029] Turn on the vacuum system, set the temperature of the heating plate, the preheating temperatures of the feed tank materials are 80°C and 50°C respectively, and the rotating speed of the rotary wiper is 380r / min. When the vacuum degree is maintained at about 1.33kPa, the raw materials are added dropwise, and after 4 minutes, the product flows out from the heavy component outlet, maintaining a stable drop rate. After 27 minutes, the dropwise addition of the material was completed. The molecular distillation device continued to operate for 15 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com