Composite annual cooling system capable of converting working modes

A cooling system and conversion work technology, applied in air conditioning systems, refrigerators, heating methods, etc., can solve problems such as low energy efficiency ratio and weak power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

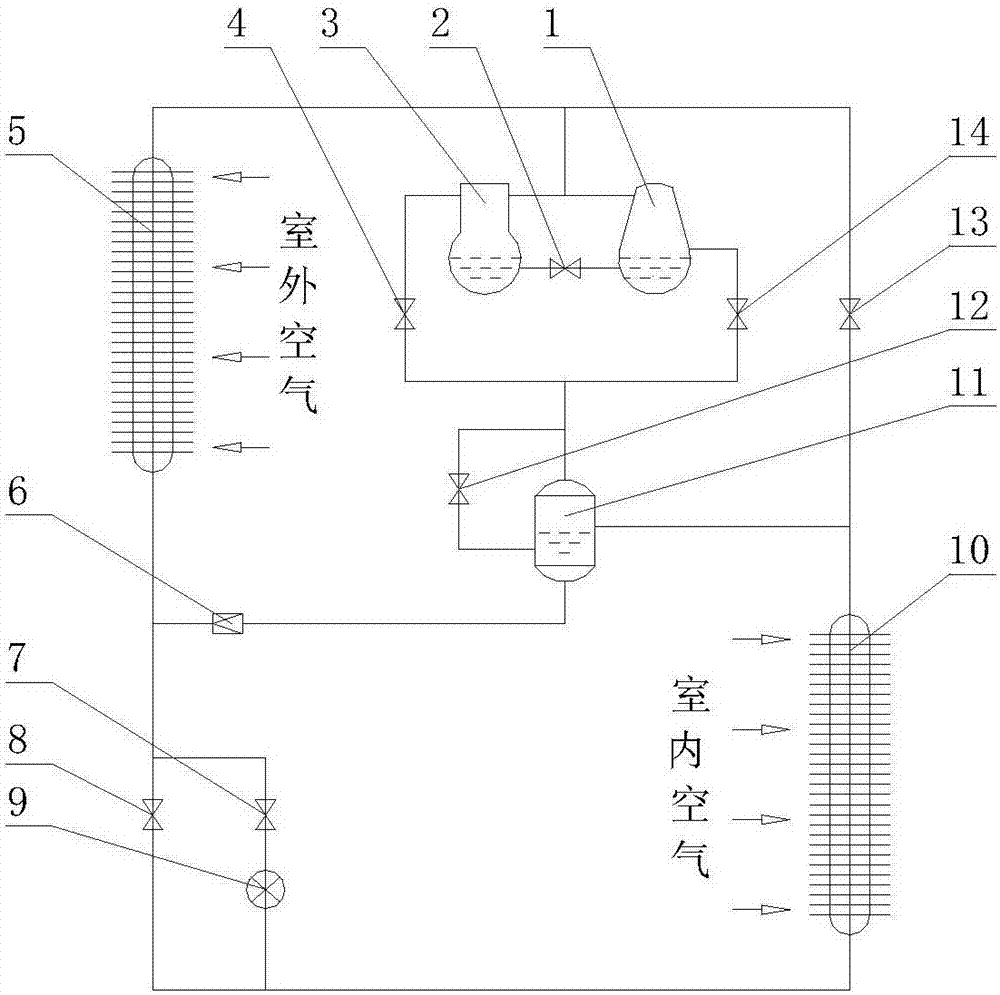

Embodiment 1

[0023] refer to figure 1 , this embodiment is a year-round cooling cooling system that can realize the conversion of three working modes: separated heat pipe, air pump driven heat pipe and mechanical refrigeration. The system consists of air pump 1, oil balance pipe 2 with control valve, compressor 3, and switching valve a4 , outdoor heat exchanger 5, one-way valve 6, switching valve b7, switching valve c8, throttling element 9, indoor heat exchanger 10, gas-liquid separator 11 with oil return port and liquid return port, with control valve Oil return pipe 12, switching valve d13, switching valve e14 and so on.

[0024] The connection relationship of the year-round cooling system is as follows: the outdoor heat exchanger 5, the switching valve 8, the indoor heat exchanger 10 and the switching valve d13 are sequentially connected into a circuit through pipelines; On the pipeline between the outdoor heat exchanger 5 and the switching valve d13, the oil balance pipe 2 with a con...

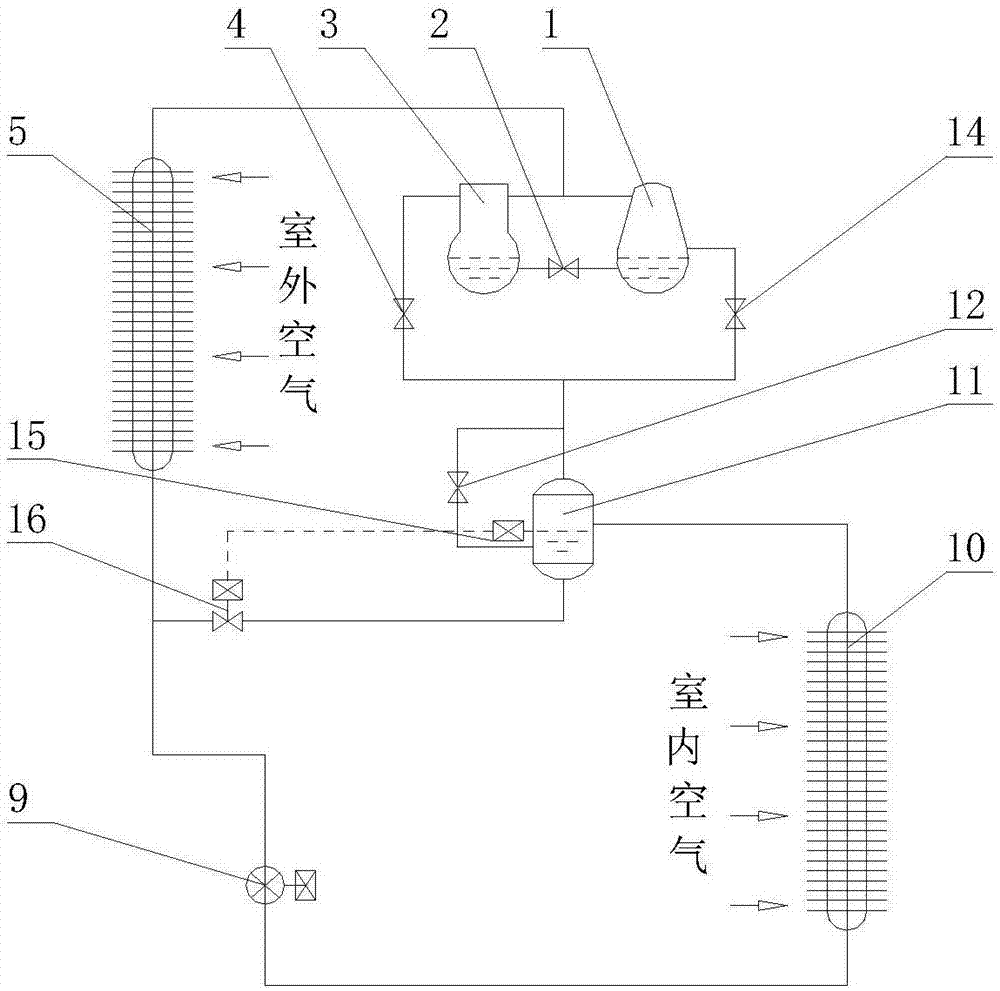

Embodiment 2

[0026] refer to figure 2 , this embodiment is an air pump-driven heat pipe compound mechanical refrigeration year-round cooling cooling system, compared with Embodiment 1, this system saves the connection from the air pump 1 and compressor 3 exhaust pipes to the inlet of the gas-liquid separator 11 The branch where the switching valve d13 at the access point is located, the switching valve b7, and the branch where the switching valve d13 is in parallel with the branch where the throttling element 9 is located. The throttling element 9 is an electric expansion valve. The one-way valve 6 is replaced by a liquid level control valve 16, and the liquid level control valve 16 is controlled by the liquid level controller 15 sensing the height of the liquid level. When the conversion valve a4 is closed and the conversion valve e14 is opened, the cooling system works in the air pump driven heat pipe mode; when the conversion valve e14 is closed and the conversion valve a4 is opened, ...

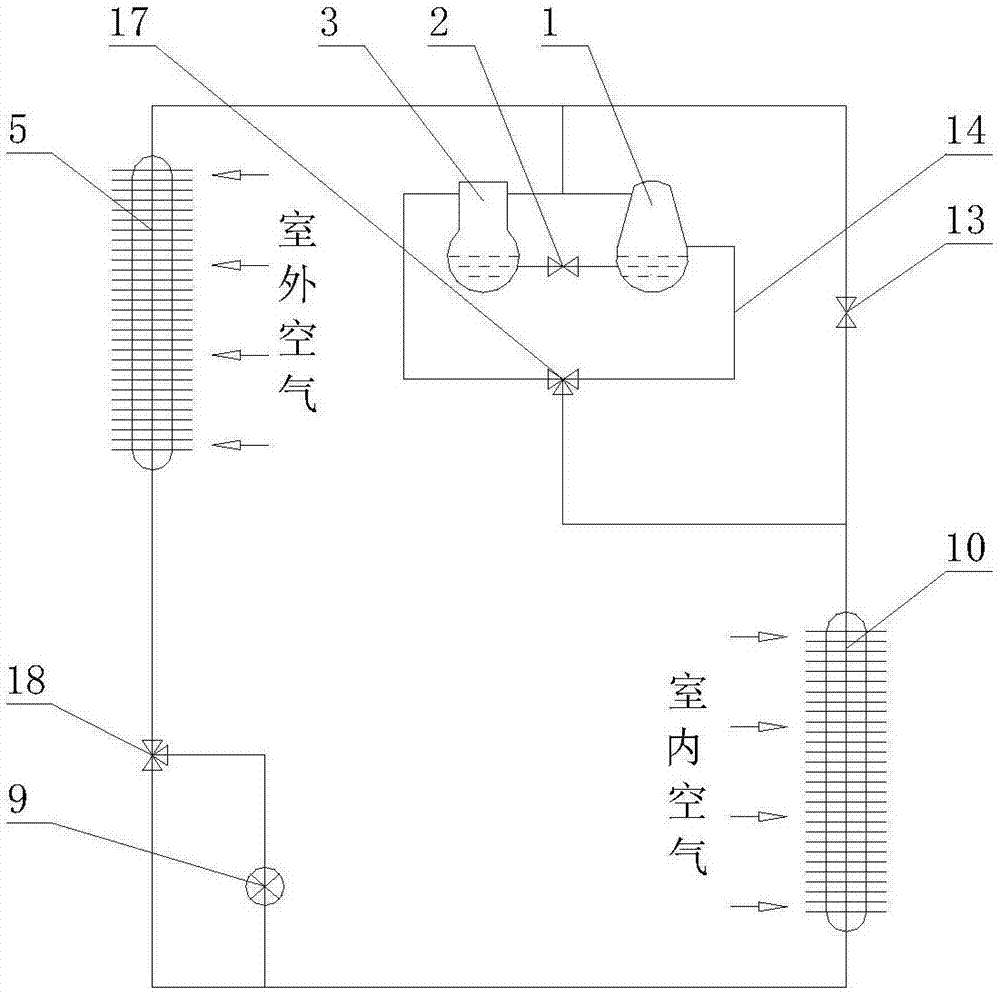

Embodiment 3

[0028] refer to image 3 , this embodiment is a year-round cooling cooling system with three working modes without a gas-liquid separator. The main difference from Embodiment 1 is: the gas-liquid separator 11 is omitted, and the air pump 1 and the compressor 3 suction pipes are now Directly connected to the pipeline between the indoor heat exchanger 10 and the switching valve d13; switching valve a4 and switching valve e14, switching valve b7 and switching valve c8 are replaced by three-way valve a17 and three-way valve b18 respectively. The system configuration and working mode conversion of other parts are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com