Determination method of adhesion number of carbon fiber precursors

A technology of carbon fiber precursor and measurement method, which is applied in the field of carbon fiber, can solve the problems of lack of testing methods, etc., and achieve the effect of standard requirements, strong comparability and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take the 1# line raw silk sample from the spinning workshop for testing:

[0023] (1) Preparation of fiber dispersant; prepare 100mL of 0.1% aqueous solution of Noigen EA-157 as fiber dispersant;

[0024] (2) intercept the 3mm fiber in a bundle of silk as the fiber sample to be tested, with a weight of 0.009g (a bundle is 24000);

[0025] (3) Transfer all the intercepted fiber samples to be tested to the fiber dispersant, and stir on a magnetic stirrer (100 revolutions / min); the fibers are evenly distributed in the solution;

[0026] (4) Quickly pour the stirred sample solution into the Buchner funnel (the diameter of the funnel is 12.5cm), and the filter paper is pre-laid in the Buchner funnel, and the sample solution does not exceed the edge of the filter paper; for the convenience of observation, black filter paper is used for the original silk ;Take out the filter paper after the dispersant is basically drained; the non-adhesive monofilaments will be evenly distrib...

Embodiment 2

[0031] Except that the raw silks tested were another batch of raw silks (the process parameters of spinning were adjusted to produce another batch of raw silks), other measurement methods were all the same as in Example 1. Cut the 3mm fiber in a bundle of silk as the fiber sample to be tested, with a weight of 0.009g (a bundle is 24000);

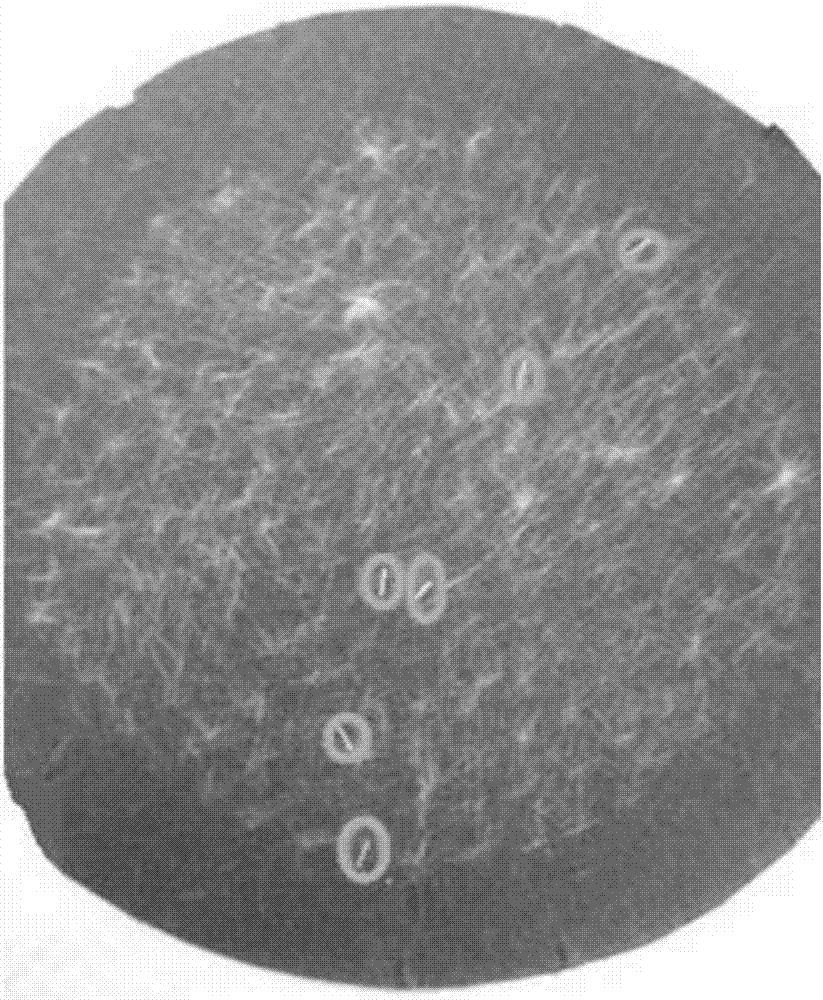

[0032] Test results: the adhesion filaments are very obvious on the filter paper and are easy to identify; the number of adhesions is 6, which can be seen figure 2 .

[0033] Sampling was repeated 5 times, and the test was carried out in the same way. The test results were: 5, 6, 6, 5, and 6. It can be seen that under the same process conditions, the batch of samples has more adhesions; the measurement results of the adhesion number are very stable and have good repeatability.

Embodiment 3

[0035] Take the pre-oxidized silk sample from the 1# line of the carbonization workshop for testing:

[0036] (1) Preparation of fiber dispersant; prepare 100mL of 0.1% aqueous solution of Noigen EA-157 as fiber dispersant;

[0037](2) intercept the 3mm fiber in a bundle of silk as the fiber sample to be tested, with a weight of 0.009g (a bundle is 24000);

[0038] (3) Transfer all the fiber samples intercepted to the fiber dispersant, stir on a magnetic stirrer, 100 rpm; make the fibers evenly distributed in the solution;

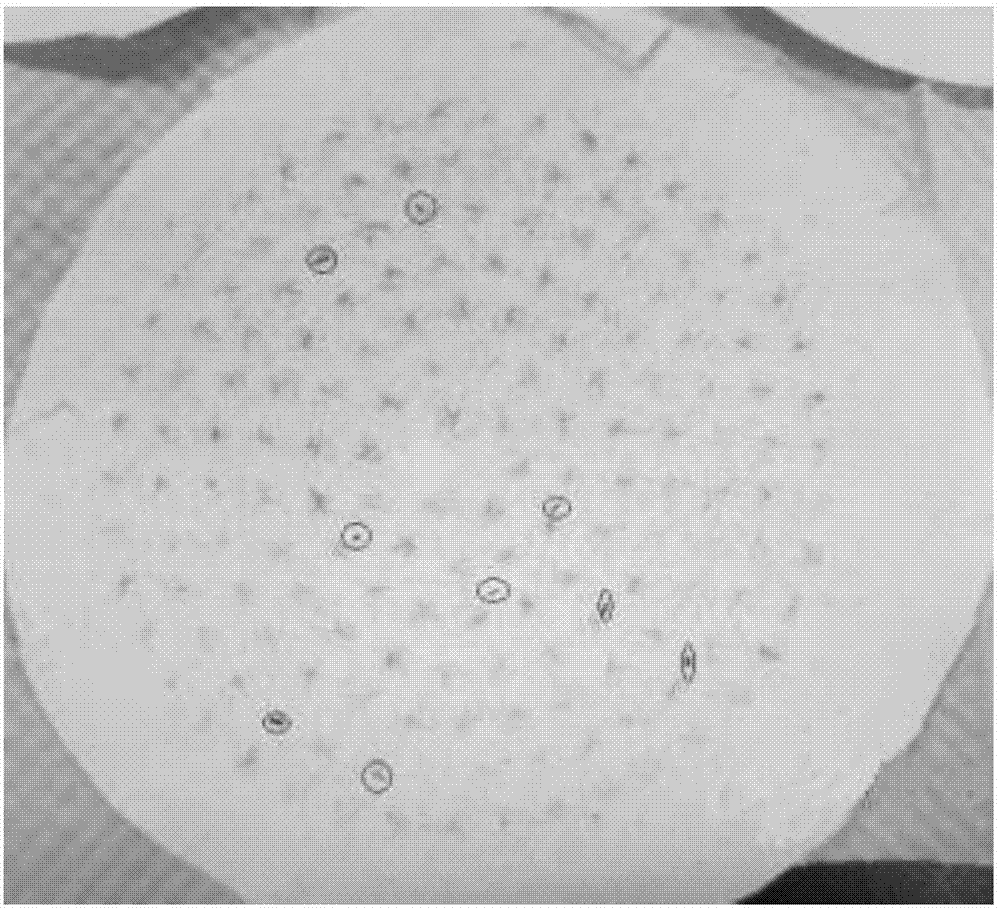

[0039] (4) Quickly pour the stirred sample solution into the Buchner funnel (funnel specification: diameter 12.5cm), and filter paper is laid in the Buchner funnel in advance. For the convenience of observation, use white filter paper for the pre-oxygenation silk; After drying, take out the filter paper; the non-adhesive monofilaments will be evenly distributed on the filter paper; the cohesive filaments will be obviously thicker than the surrounding mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com