Control system and control method for lifting transverse movement parking equipment

A parking equipment and control system technology, which is applied in the general control system, control/regulation system, sequence/logic controller program control, etc., can solve the problem of difficulty in integration, low fault tolerance, and influence on the popularization and application of lifting and lateral parking equipment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following description.

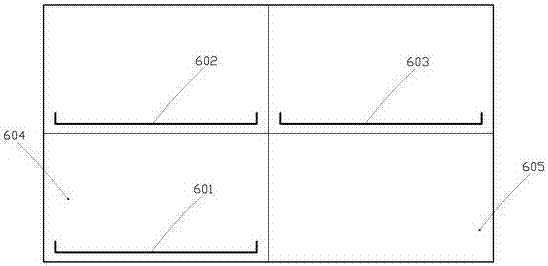

[0092] figure 1 As shown in the figure, it is the simplest layout diagram of the lifting and traversing parking equipment. It can be seen from the figure that the parking equipment has two floors and two columns, the lower part is the entry and exit floor, and there is a vehicle loading plate No. 101 No. 6-1, which can move left / right on the entry and exit floor; the top is the highest floor ( That is, the second floor) has vehicle loading board No. 6-2 of 201 and vehicle loading board No. 6-3 of 202. These two loading boards can only be raised / lowered between the second floor and the access floor; as shown in the figure The left side of the access floor is parking space 1 6-4, and the right side is parking space 2 6-5.

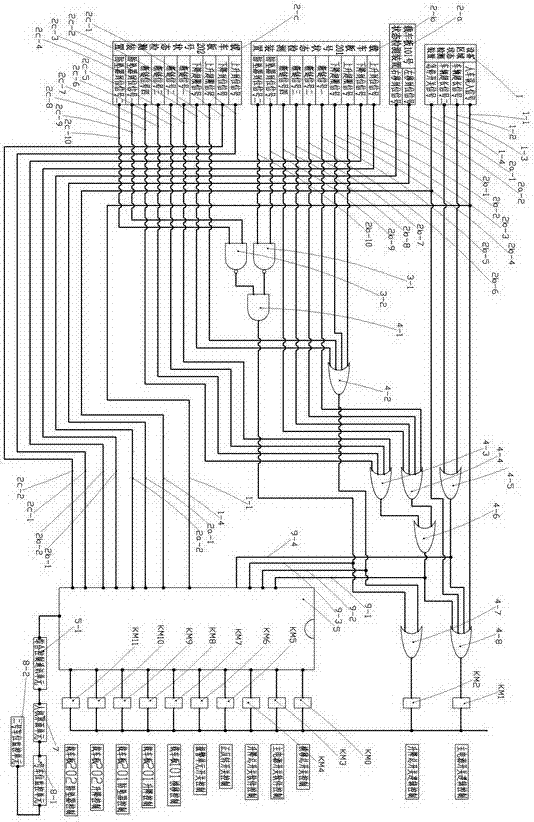

[0093] figure 2 shown, for the figure 1 The schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com