Sensor system for determining temperature and rotational characteristics of rotating element

A temperature sensor and rotating element technology, applied in the field of sensor systems, can solve the problems of permanent magnet demagnetization, cost, lack of measurement information, limit motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

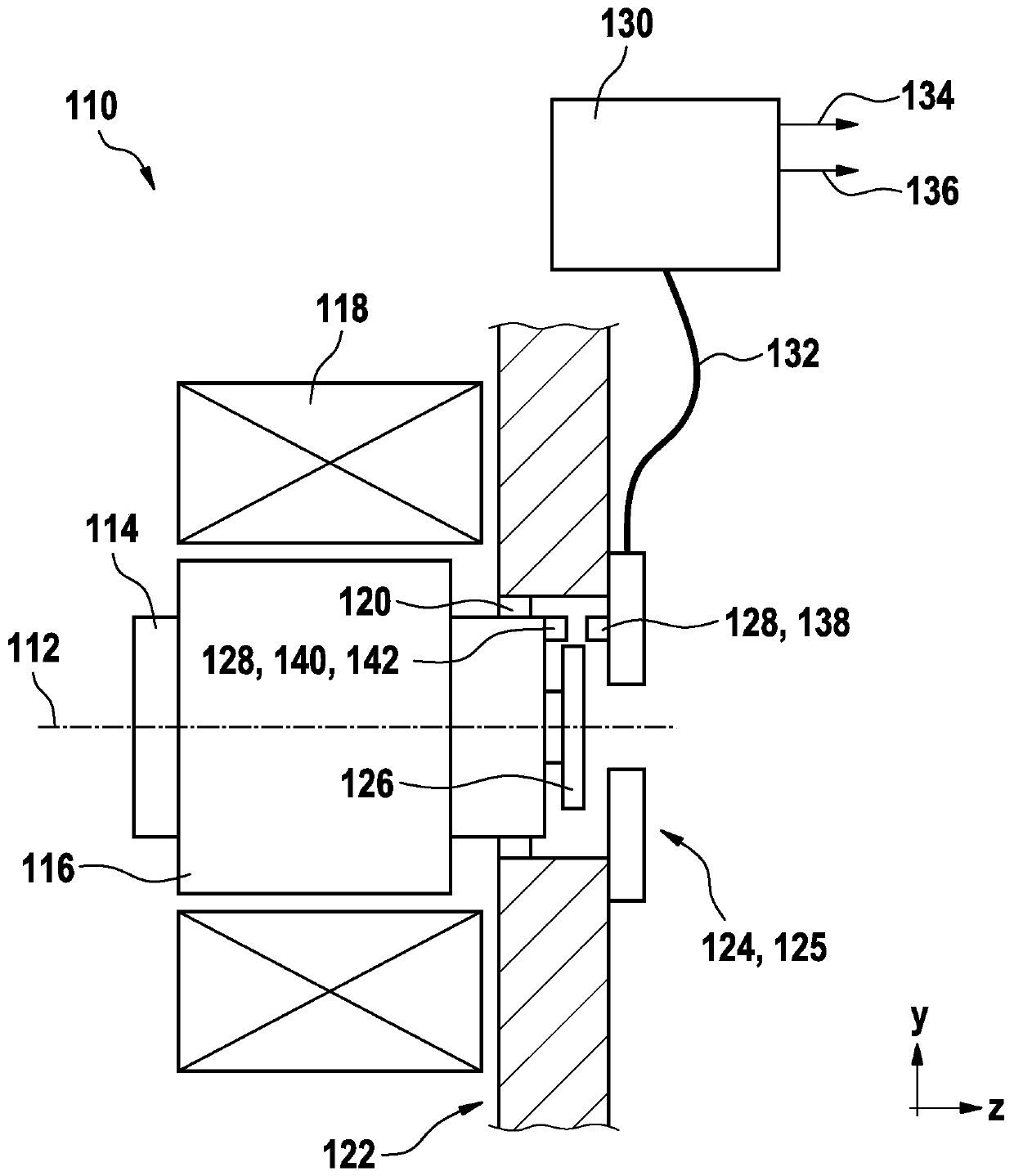

[0051] figure 1 A schematic illustration of a sensor system 110 according to the invention according to an embodiment is shown. The sensor system 110 is provided for determining at least one rotational characteristic of a rotational element 114 about at least one rotational axis 112 . In particular, sensor system 110 may be provided for use in a motor vehicle. In particular, sensor system 110 may be provided for sensing at least one rotational characteristic of the camshaft. Sensor system 110 may be configured, for example, to sense the angular position of a camshaft. Correspondingly, the rotating element 114 can be, for example, a shaft. In the case of the shown constant field synchronous machine, the shaft may carry permanent magnets 116 . The stator coil pack 118 can be arranged cylindrically around the permanent magnet 116 . The output device can be arranged in the negative z-direction and is not shown again. On the side opposite the output, a B bearing 120 can be ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com