A flexible touch motherboard and its preparation method, flexible touch substrate, touch panel

A flexible touch and motherboard technology, applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., to achieve low square resistance, avoid bubbling defects, and improve product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

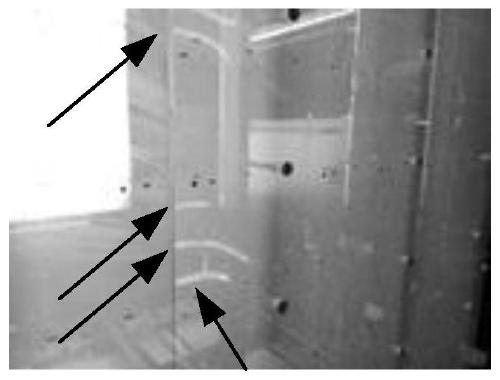

[0037] The embodiment of the present invention provides a method for preparing a flexible touch motherboard, such as figure 2 As shown, the preparation method includes,

[0038] Step S01, patterning the first transparent conductive layer formed on the flexible film to form a plurality of intersecting first electrodes and second electrodes located in the display area; wherein, the first transparent conductive layer is deposited by multiple times The multi-layer first transparent conductive film is formed; the thickness of the deposited first layer of the first transparent conductive film is 15-45nm, and the total thickness of the multi-layer first transparent conductive film is 120-200nm.

[0039] It should be noted that, first, the above-mentioned flexible touch motherboard provided by the embodiment of the present invention includes multiple display areas, which can be divided into multiple small pieces, that is, a single flexible touch substrate, each flexible Each touch su...

Embodiment 2

[0088] Furthermore, the embodiment of the present invention also provides a flexible touch control board, which is prepared by the above preparation method. It can obtain a relatively flat surface while having a low electrode channel impedance, and is the first in the industry to realize the Roll to Sheet low square resistance process.

Embodiment 3

[0090] Furthermore, the embodiment of the present invention also provides a flexible touch substrate, which is any one of the multiple sub-substrates cut from the above-mentioned flexible touch motherboard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com