Custard premixed powder containing oat bran and application method of custard premixed powder

A technology of oat bran and premixed powder, applied in the field of food additives, can solve the problems of lack of change and innovation, achieve good nutritional value and improve water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

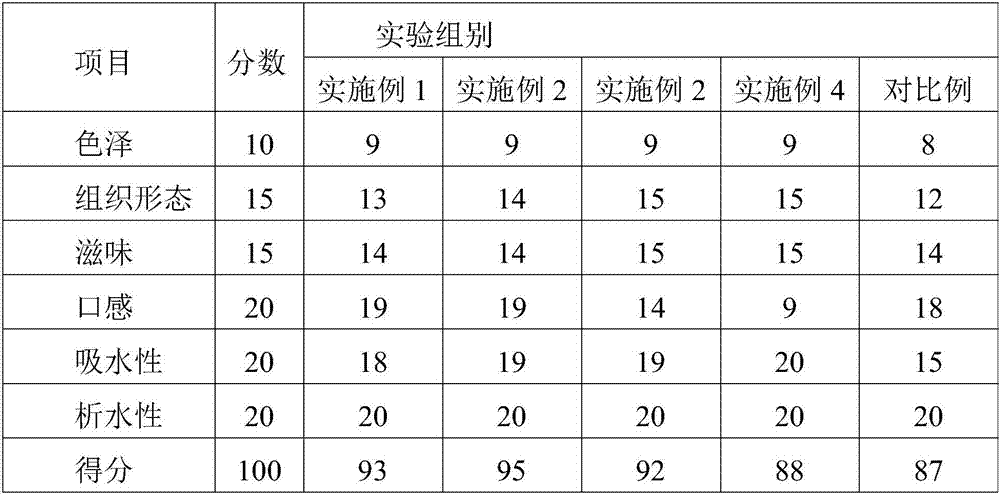

Embodiment 1

[0028] The composition of the Casida pre-mixed powder in this embodiment is: corn starch 56%, icing sugar 35%, oat bran 3%, pregelatinized modified hydroxypropyl distarch phosphate 3.5%, whole milk powder 2%, β-carotene 0.2%, turmeric 0.1%, food flavor 0.2%.

[0029] The above-mentioned application method of custard premixed powder for making custard filling includes the following steps:

[0030] S1: Weigh 200g of Casida premix powder containing oat bran and 600g of water;

[0031] S2: The water is heated to about 50°C;

[0032] S3: Pour the water into the mixing tank, add the Kasta premix powder while stirring slowly, and mix for about 3 minutes until there are no visible particles;

[0033] S4: Let stand for 5 minutes to taste.

Embodiment 2

[0035] The composition of the pre-mixed custard powder in this embodiment is: corn starch 56%, powdered sugar 35%, oat bran 4%, pregelatinized modified hydroxypropyl distarch phosphate 2.5%, and whole milk powder 2%. β-carotene 0.2%, turmeric 0.1%, food flavor 0.2%.

[0036] The application method of the above-mentioned custard premixed powder in making custard filling is the same as the application method of Example 1.

Embodiment 3

[0038] The composition of the Casida premixed powder of this embodiment is: 55.5% of corn starch, 35% of powdered sugar, 5% of oat bran, 2% of hydroxypropyl distarch phosphate, 2% of whole milk powder, and 0.2% of β-carotene. , Turmeric 0.1%, food flavor 0.2%.

[0039] The application method of the above-mentioned custard premixed powder in making custard filling is the same as the application method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com