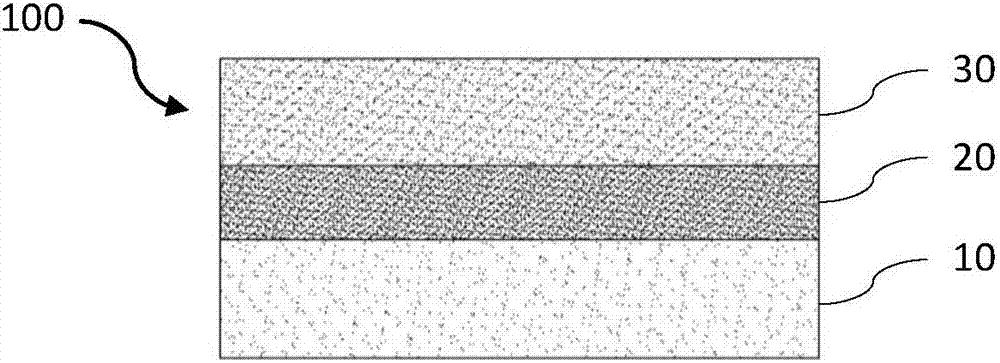

Integrated three-layer composite scaffold for repairing joint cartilages, and production method thereof

A technology of articular cartilage and layer compounding, applied in prostheses, bone implants, medical science, etc., can solve problems such as weak interlayer bonding, achieve good interlayer bonding, improve overall structural stability, and high flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing an integrated three-layer composite scaffold for articular cartilage repair, comprising the following steps:

[0039] (1) Preparation of sodium alginate slurry: first take a certain amount of sodium alginate and add it to water and stir at a certain temperature. After dissolving, add a certain amount of sodium alginate and stir quickly evenly. Sodium alginate slurry is obtained after sieving, and sealed for preservation;

[0040] Wherein, the concentration of the sodium alginate slurry is 0.08-0.3 g / mL.

[0041] (2) Preparation of bioceramic particles / sodium alginate composite slurry: take a certain amount of bioceramic particles sieved through a 200-800-mesh sieve, add it to the sodium alginate aqueous solution, stir quickly and pass through a 200-800-mesh sieve Sieve through a net to obtain a bioceramic particle / sodium alginate composite slurry, which is sealed and stored;

[0042] Among them, the mass ratio...

Embodiment 1

[0049] (1) Take 0.8g of sodium alginate and add it into 10mL of ultrapure water at 95°C and stir to dissolve it. After dissolving, add 2g of sodium alginate and stir evenly. Pass the uniformly mixed slurry through a 400-mesh sieve to obtain sodium alginate slurry materials, and then sealed and stored.

[0050] (2) Pass the bioactive glass powder through a 400-mesh sieve, then take 1g of bioactive glass powder and 1g of sodium alginate powder and add it to 10mL of sodium alginate aqueous solution (concentration: 0.08g / mL), stir quickly and evenly, and mix The uniform slurry is passed through a 400-mesh sieve to obtain a bioactive glass particle / sodium alginate composite slurry, which is then sealed and stored.

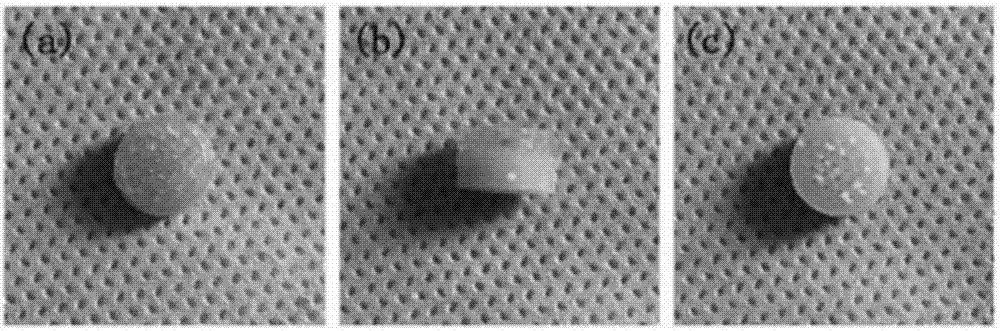

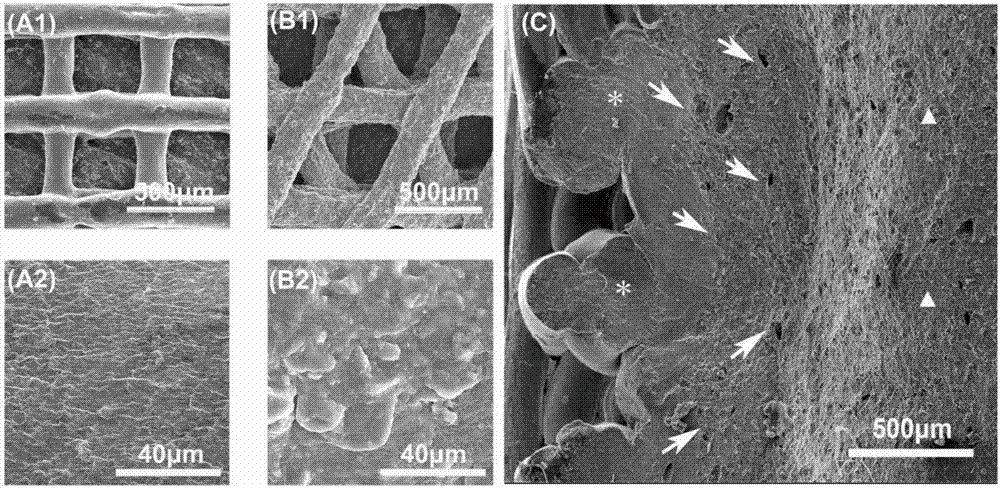

[0051] (3) Using CAD / CAM computer-aided software to design the appearance and internal structure of the three-layer composite bracket, the obtained bracket model is a cylinder (diameter 8mm, height h is 3mm), the internal pore diameter is 200μm, the first eight slurry...

Embodiment 2

[0055] (1) Take 0.8g of sodium alginate and add it into 10mL of ultrapure water at 95°C and stir to dissolve it. After dissolving, add 2g of sodium alginate and stir evenly. Pass the uniformly mixed slurry through a 300-mesh sieve to obtain sodium alginate slurry materials, and then sealed and stored.

[0056] (2) Pass the bioactive glass powder through a 300-mesh sieve, then take 0.5g of bioactive glass powder and 1.5g of sodium alginate powder and add it to 10mL of sodium alginate aqueous solution (concentration: 0.08g / mL), stir quickly and evenly, Pass the uniformly mixed slurry through a 300-mesh sieve to obtain a bioactive glass particle / sodium alginate composite slurry, which is then sealed and stored.

[0057] (3) Using CAD / CAM computer-aided software to design the appearance and internal structure of the three-layer composite bracket, the obtained bracket model is a cylinder (diameter 8mm, height h is 3mm), the internal pore diameter is 400μm, the first eight pulp su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com