Reciprocating tea turning and throwing compacting mechanism

A technology of reciprocating and resetting mechanism is applied in the field of reciprocating tea turning, throwing and compacting mechanism, which can solve problems such as low molding efficiency, and achieve the effects of improving production efficiency, reducing labor intensity and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

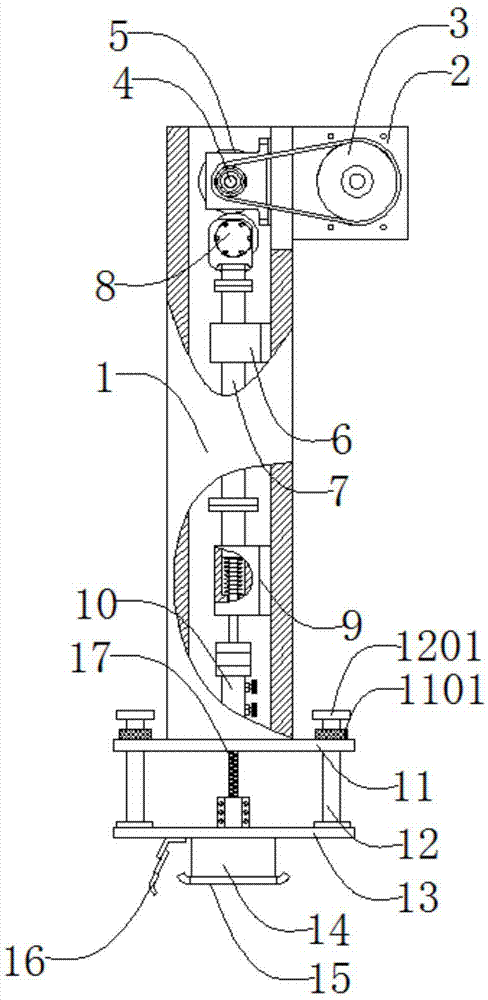

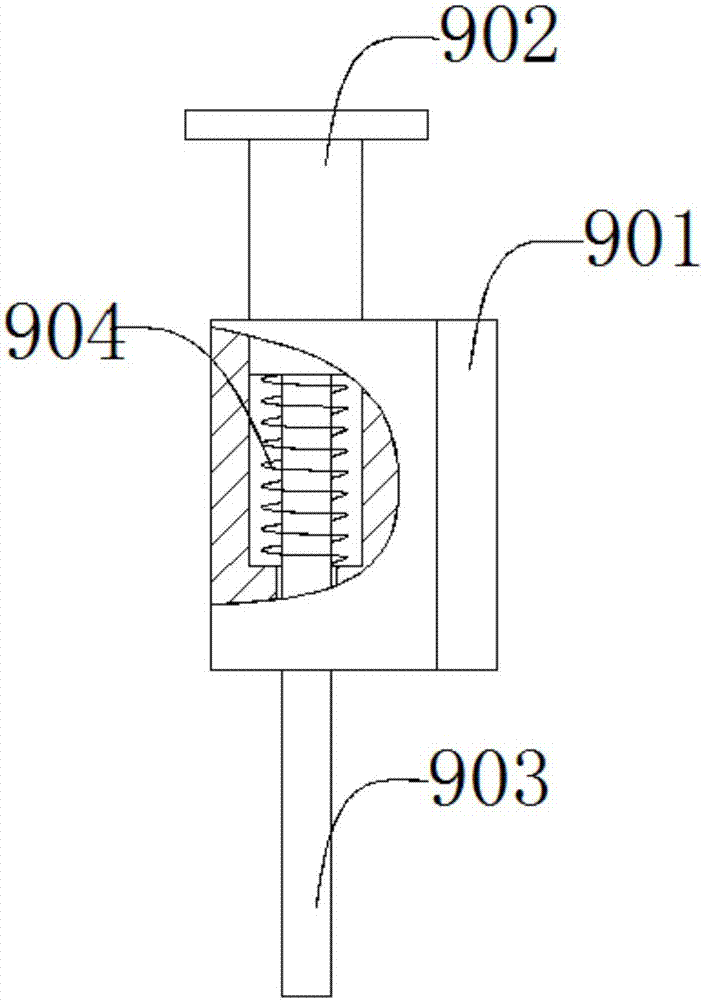

[0025] Such as figure 1 , figure 2 As shown, a reciprocating tea turning and compacting mechanism includes a housing 1, a speed regulating motor 2, a transmission mechanism 3, a rotating shaft 4, a cam 5, a guide seat 6, a square push rod 7, a guide wheel 8, and a reset mechanism 9 , collet 10, upper supporting plate 11, guide rod 12, lower supporting plate 13, briquetting block 14, pressing plate 15, material rake 16, steel wire rope 17, described speed-regulating motor 2 is located at the upper end of the right side of housing 1, and described The speed-regulating motor 2 is threadedly connected with the housing 1, the transmission mechanism 3 is located on one side of the speed-regulating motor 2 and runs through the housing 1, the transmission mechanism 3 is connected with the speed-regulating motor 2 by keys, and the rotating shaft 4 Located at the upper end of the inner side of the housing 1 and on the side of the transmission mechanism 3, the rotating shaft 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com