Pressure holding fixture

A clamping and clamping technology, which is applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of easy wear or breakage of buckles, high development cost of clamping fixtures, and low efficiency of disassembly and assembly, so as to achieve easy disassembly and assembly, Save jig cost and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

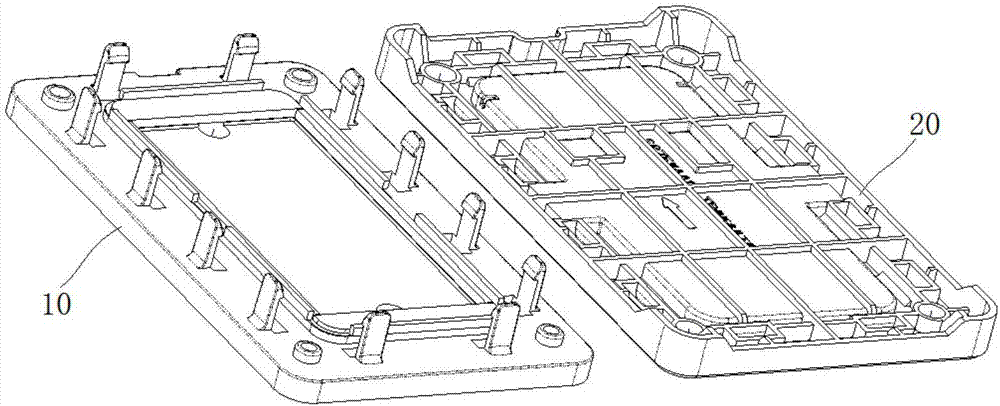

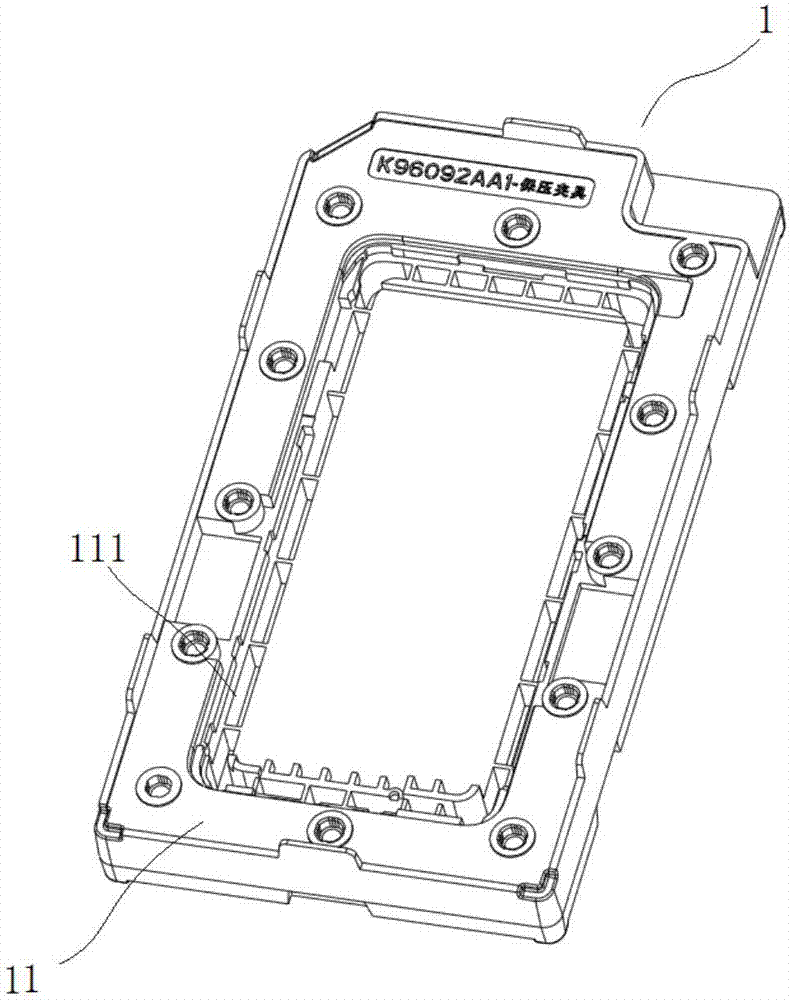

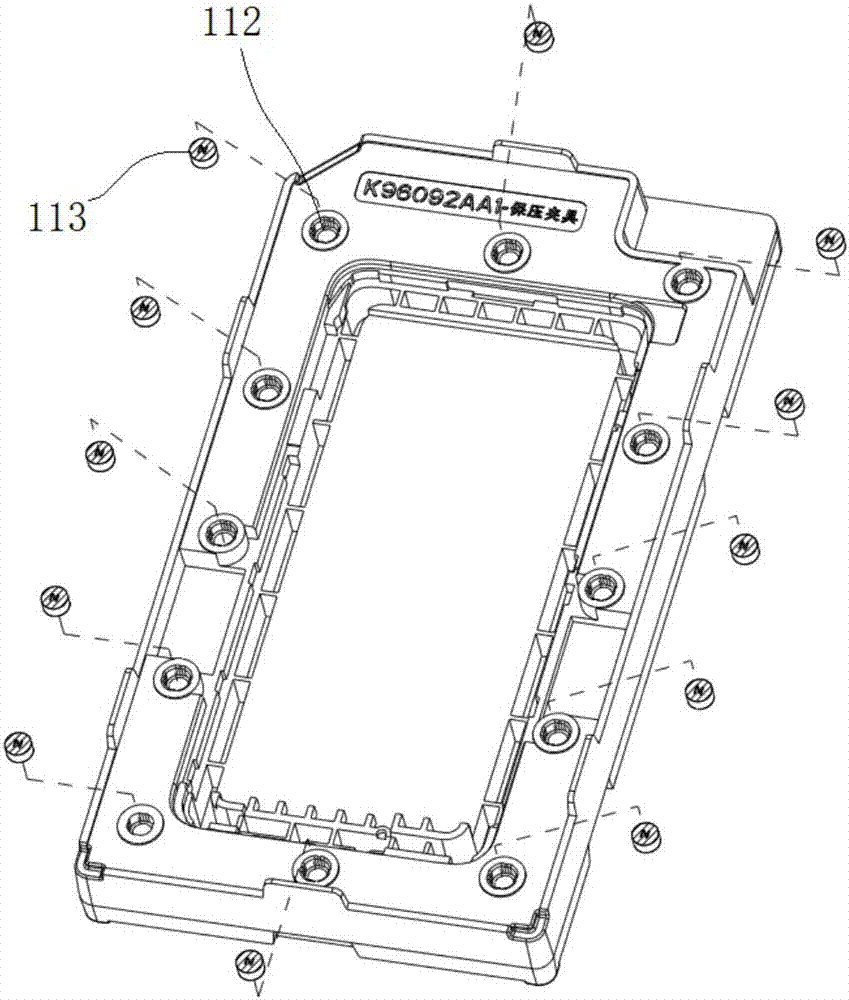

[0029] see Figure 2 to Figure 9 , the present invention discloses a pressure maintaining fixture, which comprises: several clamp units 1, the middle part of the first surface 11 of each clamp unit 1 is provided with a groove 111 for placing a pressed object, each clamp unit 1 The first surface 11 of each clamp unit 1 is used as the lower clamp surface, and the second surface 12 of each clamp unit 1 is used as the upper clamp surface. The upper clamp surface of one clamp unit 1 can cooperate with the lower clamp surface of another clamp unit 1 to complete the pressure maintaining action (such as Figure 7 , Figure 9 shown).

[0030] The periphery of the groove 111 is provided with several circular grooves 112, and the first magnetic mechanism 113 is arranged in the circular groove 112; the second surface 12 of the clamp unit 1 is provided with several circular grooves 122, and the circular grooves A second magnetic mechanism 123 opposite to the first magnetic mechanism 113...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com