A frost sensor utilizing an evaporating pipe as an electrode

A technology of evaporating tubes and sensors, which is applied in the field of sensors, can solve the problems of reducing sensor sensitivity, etc., and achieve the effects of improving defrosting effect, improving refrigeration efficiency, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

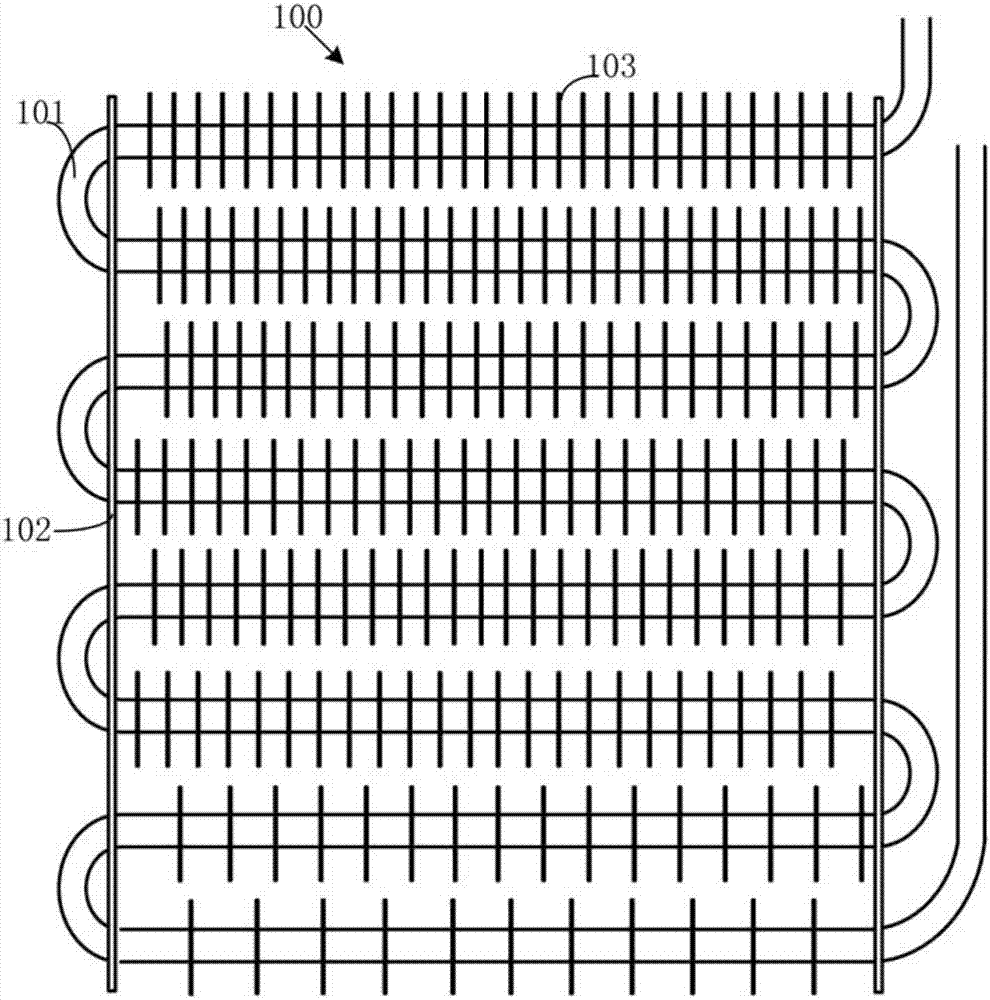

[0029] see figure 1 As shown, it is a common refrigerator finned evaporator 100 at present, in which the frame 102 is used for fixing; Large heat exchange area, so the fins 103 must have good thermal contact with the evaporation tube 101. Evaporation tubes are generally made of copper / aluminum tubes with a circular outer diameter, and the common size generally ranges from 6 to 9 mm; the fins are made of aluminum alloy sheets, which is conducive to heat dissipation. Usually the frosting of the evaporator starts from the evaporating tube and is mainly attached to the fins. The frosting efficiency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com