Feeding trough for cattle raising

A technology of feeding troughs and storage bins, applied in applications, animal feeding devices, animal husbandry, etc., can solve the problems of feed residue, feed waste, feed slipping, etc., to avoid waste, reduce labor intensity, and simplify the feeding process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

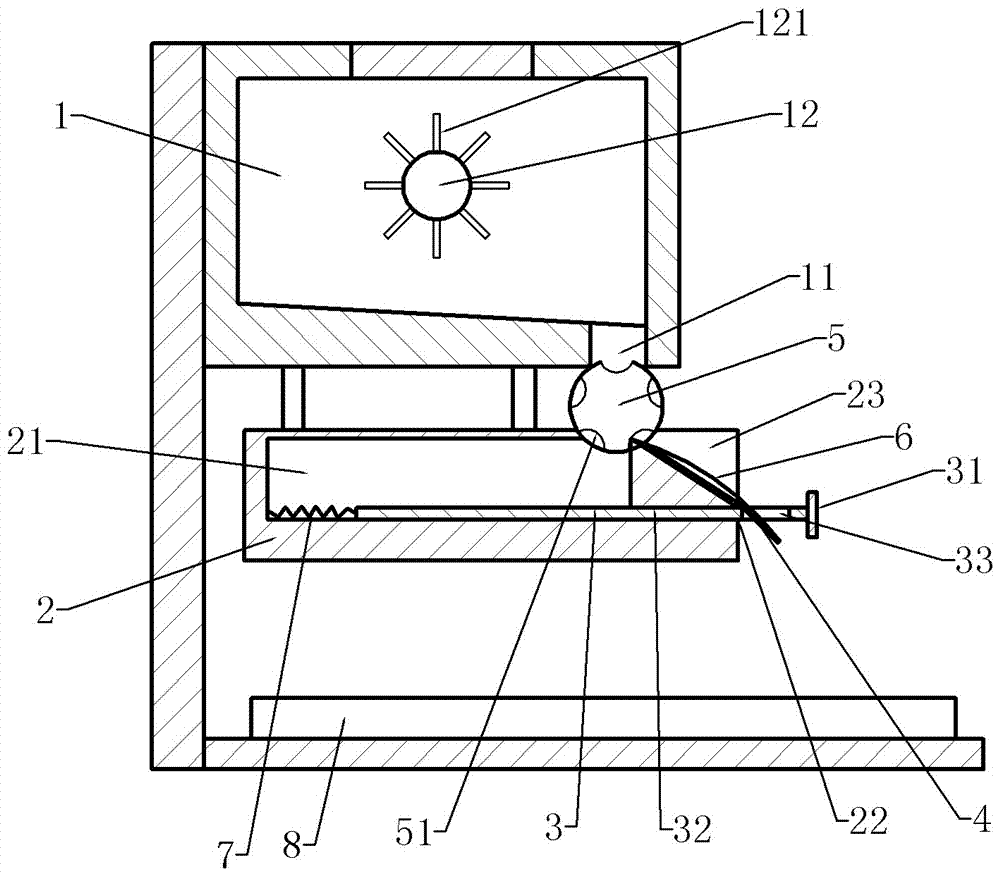

[0032] Such as figure 1 As shown, a feeding trough 8 for raising cattle includes a support frame, a feeding trough 8 is provided at the bottom of the support frame, and a storage bin 1 is provided at the top of the support frame. The top of the storage bin 1 is provided with a feed port, the feed port is threadedly connected with a sealing cover, the bottom of the storage bin 1 is inclined, and the left end of the bottom of the storage bin 1 is higher than the right end, and the right end of the bottom of the storage bin 1 is provided with a There is a discharge port 11, and the feeding trough 8 is located below the discharge port 11. The storage bin 1 is rotatably connected with a rotating shaft 12, the rotating shaft 12 runs through the storage bin 1, and the middle part of the rotating shaft 12 is provided with a stirring blade 121, and the left end of the rotating shaft 12 outside the storage bin 1 is provided with a driven gear.

[0033] It also includes an eating mechan...

Embodiment 2

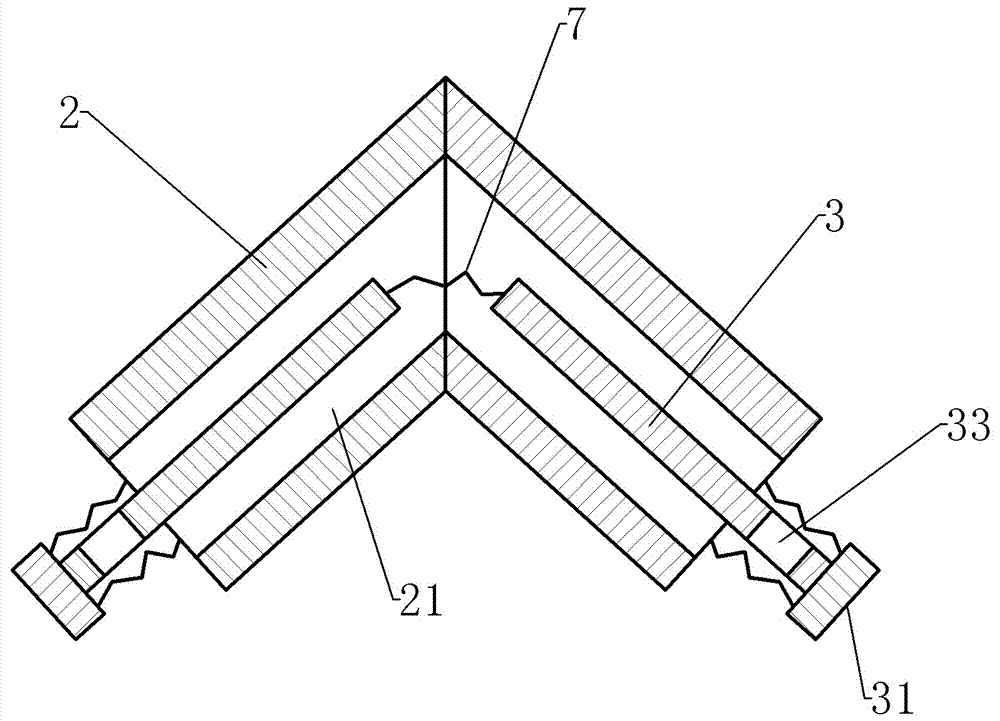

[0040] Embodiment 2 differs from Embodiment 1 only in that, as figure 2 As shown, there are two feeding mechanisms and feeding openings, and the supporting blocks 2 of the two feeding mechanisms are arranged in a V shape, and the two supporting blocks 2 are not provided with one end of the mounting hole 22. The cavity 21 of the block 2 communicates. The spring 7 is arranged between the two push rods 3 , and the spring 7 is also arranged between the block 31 and the supporting block 2 .

[0041] When using this embodiment, when the calf is close to the feeding trough 8, squeeze the push rod 3 on the right side, so that the push rod 3 on the right side drives the cutting block 32 to move, thereby driving the baffle plate 4 to move to close the storage tank 23, and The unloading roller 5 is driven to rotate so that the feed in the discharge trough 51 enters the storage trough 23 . When the push rod 3 on the right side moves, the push rod 3 on the left side is driven to move by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com