Castanea mollissima sorting device and method

A sorting device and chestnut technology, applied in sorting and other directions, can solve problems such as incomplete visual processing, low efficiency of chestnut grading, cumbersome grading steps, etc., achieve all-round shooting analysis, realize fully automated production, and optimize grading effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

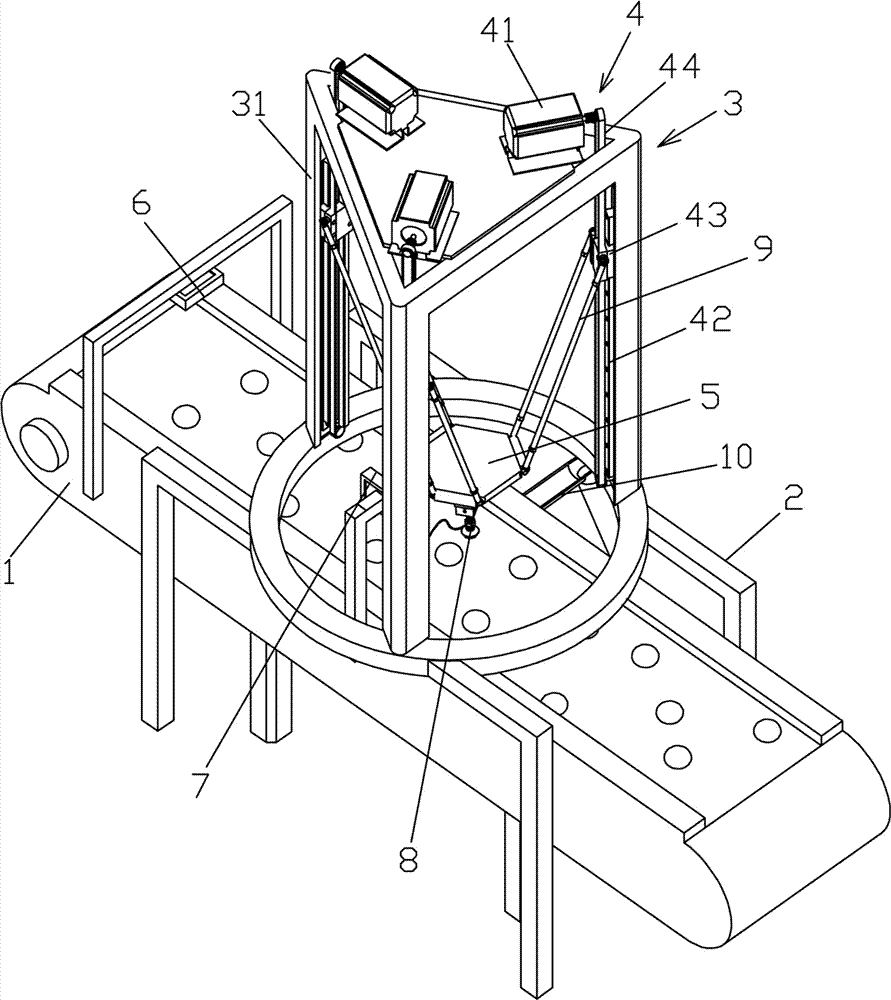

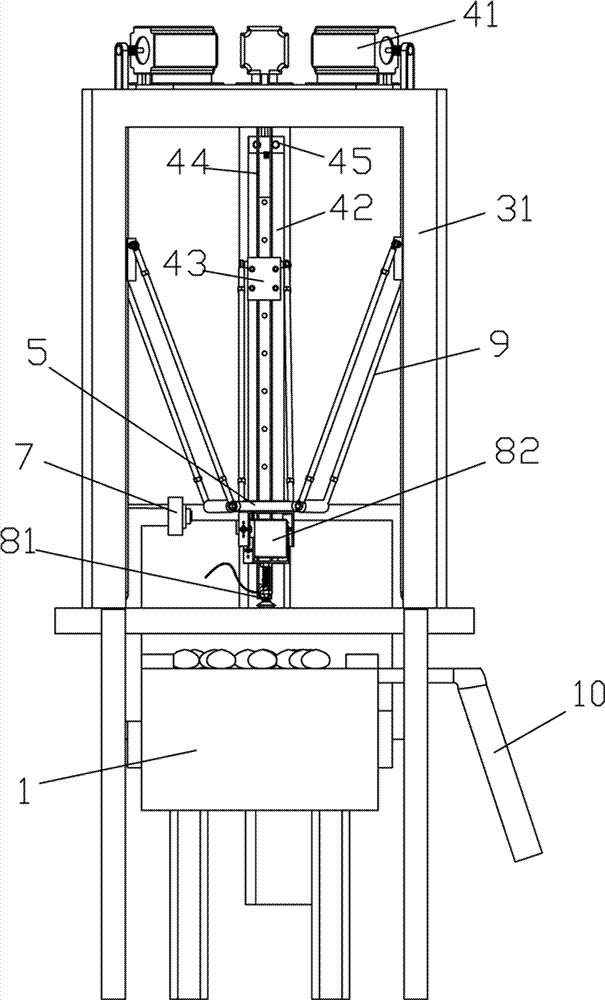

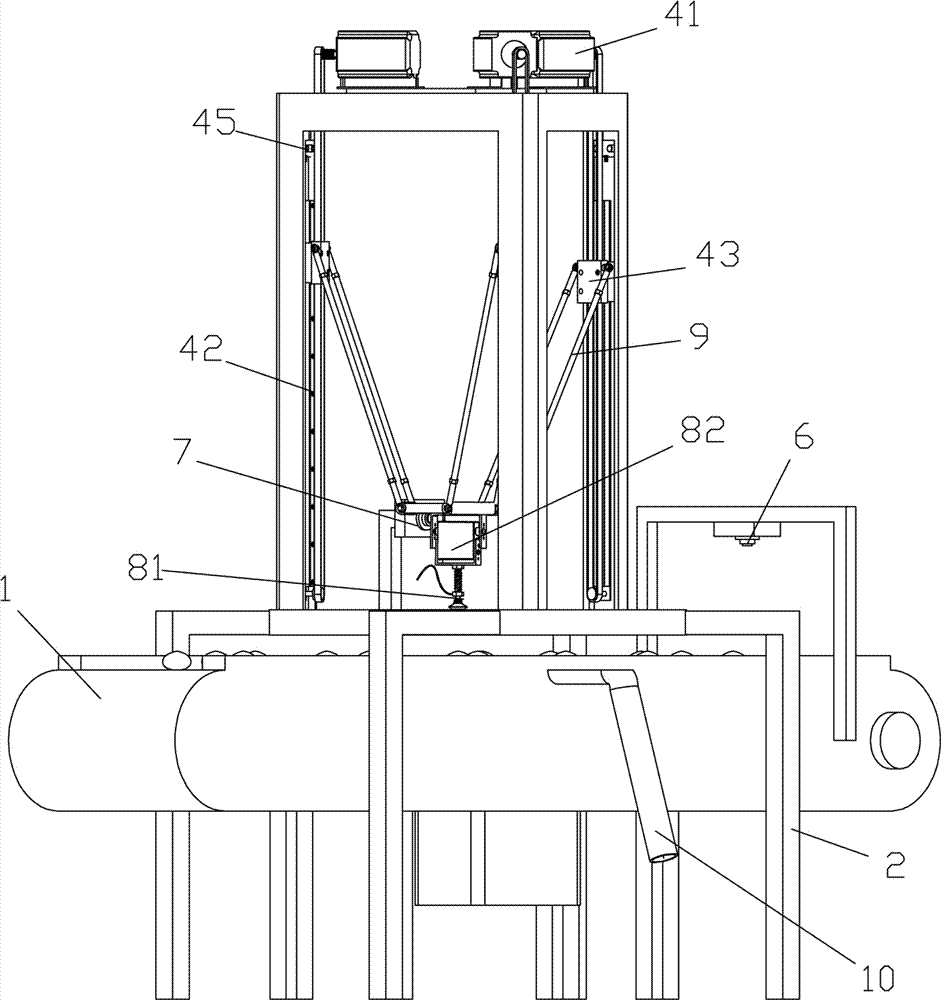

[0026] A chestnut sorting device, comprising a frame 2, a support frame 3, a conveyor 1, a movable platform 5, a suction mechanism 8, three groups of drive mechanisms 4, a first camera 6, a second camera 7, a PLC controller and a computer;

[0027] The conveyor 1 is located in the frame 2, and the support frame 3 is fixed on the frame 2. The support frame 3 includes three vertical poles 31, and the three groups of driving mechanisms 4 are respectively installed on the three vertical poles 31. The movable platform 5 is located on the conveyor In the support frame 3 above 1, a discharge pipe 10 is provided on one side of the conveyor 1;

[0028] The driving mechanism 4 includes a servo motor 41 fixed on the upper end of the pole 31, a guide rail 42 fixedly installed on the pole 31, a slider 43 installed on the guide rail 42, and two ends are respectively hinged with the slider 43 and the movable platform 5 The connecting rod 9 and the ranging sensor 45 installed on the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com