Surface correcting device for roller of cold-rolling mill

A roll surface, cold rolling mill technology, applied in the field of cold rolling mill roll surface correction device, can solve the problems of different roll surface wear, lower product qualification rate, easy surface color difference, etc., to reduce workpiece loss and improve processing quality , Simple and efficient detection operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

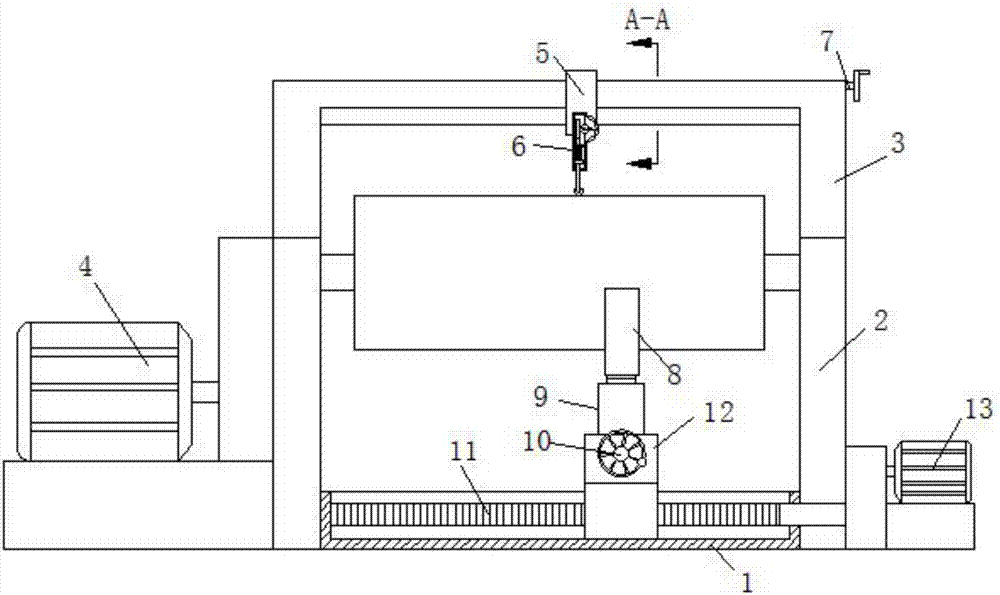

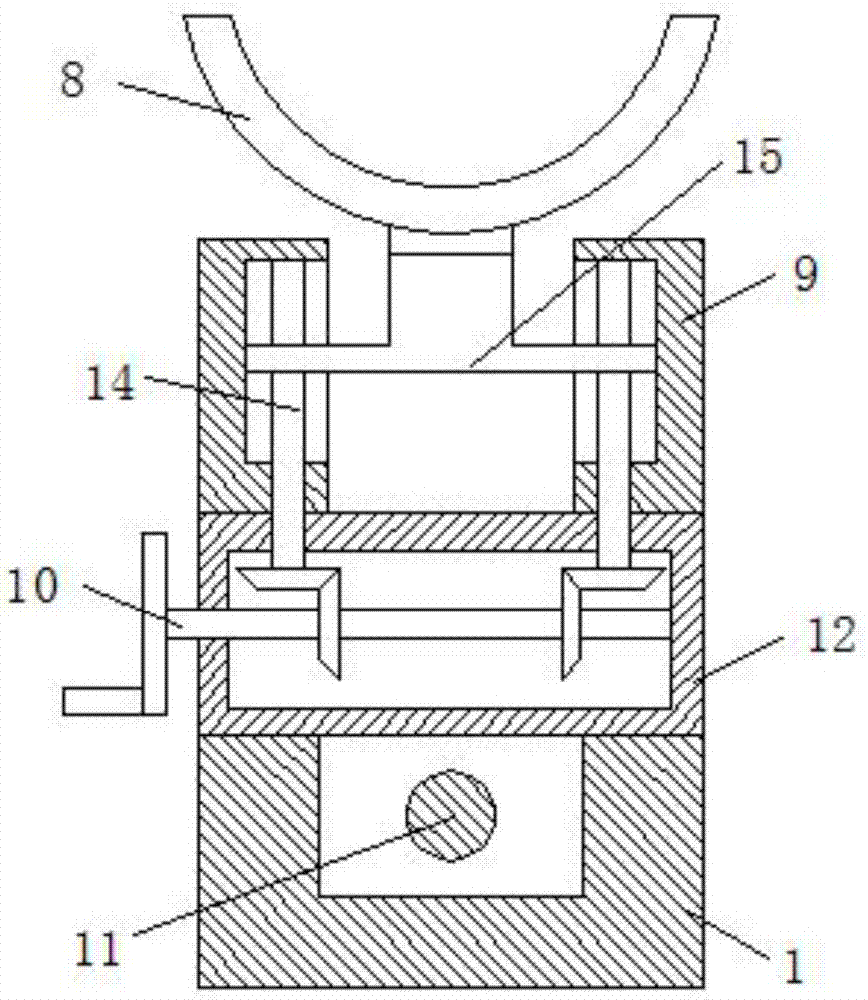

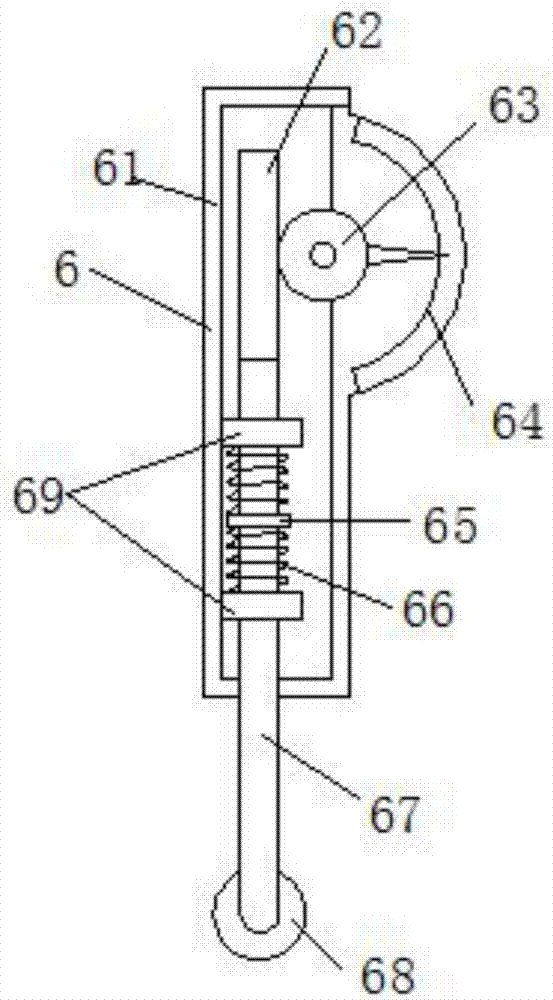

[0018] Such as Figure 1-4 As shown, a cold rolling mill roll surface correction device includes a base 1, a stand 2, a support rod 3 and a main motor 4, and two sets of the stand 2 are vertically fixed on the two ends of the base 1, and the support rod 3 is a C-shaped structure, and the support rod 3 is fixed on the upper end of the stand 2, the inside of the base 1 is provided with a screw 11, and the base 1 is provided with a lifting box 12, and the lifting box 12 is connected by a thread Lead screw 11, the upper surface of the lifting box 12 is symmetrically provided with two groups of columns 9 parallel to each other and vertically upward, the inside of the column 9 is provided with a lifting screw 14, and the lifting screw 14 of the two groups is connected to the lifting seat 15 by threads , the lifting seat 15 is fixedly provided with a grinding ring 8, a sliding seat 5 is slidably socketed on the crossbeam of the support rod 3, a rocker 7 is arranged inside the crossbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com